Waste book paper dust remover

The technology of a dust collector and this paper is applied in the field of papermaking equipment, which can solve the problems of high consumption of deinking chemicals, affecting normal production, and equipment blockage, etc., and achieves the effects of simple and practical structure, low maintenance cost, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

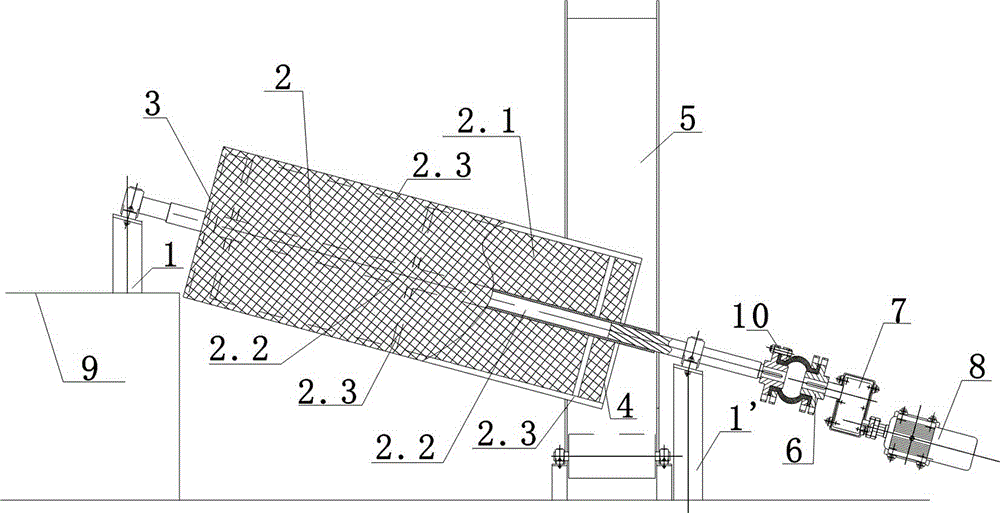

[0018] Such as figure 1 As shown, a waste book paper dust collector includes a cylindrical mesh cage 2 installed on the frame. The cylindrical mesh cage 2 is installed on the frame in an inclined shape, and the cylindrical mesh cage 2 is relatively high. One end is provided with a feed inlet 3, and the lower end of the cylindrical mesh cage 2 is provided with a discharge outlet 4, and a belt conveyor 5 is arranged below the discharge outlet 4, and the cylindrical mesh cage 2 is connected with a driving device.

[0019] The cylindrical mesh cage 2 includes a cylindrical steel wire mesh 2.1, a main shaft 2.2, and a plurality of support pipes 2.3, and the main shaft 2.2 runs through the cylindrical steel wire mesh 2.1 from the feed port 3 to the discharge port 4, and a plurality of support pipes One end of the pipe 2.3 is connected to the main shaft 2.2, and the other end is fixedly connected to the inner wall of the cylindrical wire mesh 2.1. The main shaft 2.2 is a steel pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com