Comprehensive utilization method of iron, heat and slag of converter slag and desulfurization slag

A technology for desulfurization slag and converter slag, applied in the field of steelmaking, can solve the problems of high recovery rate of slag metal iron and high added value of tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

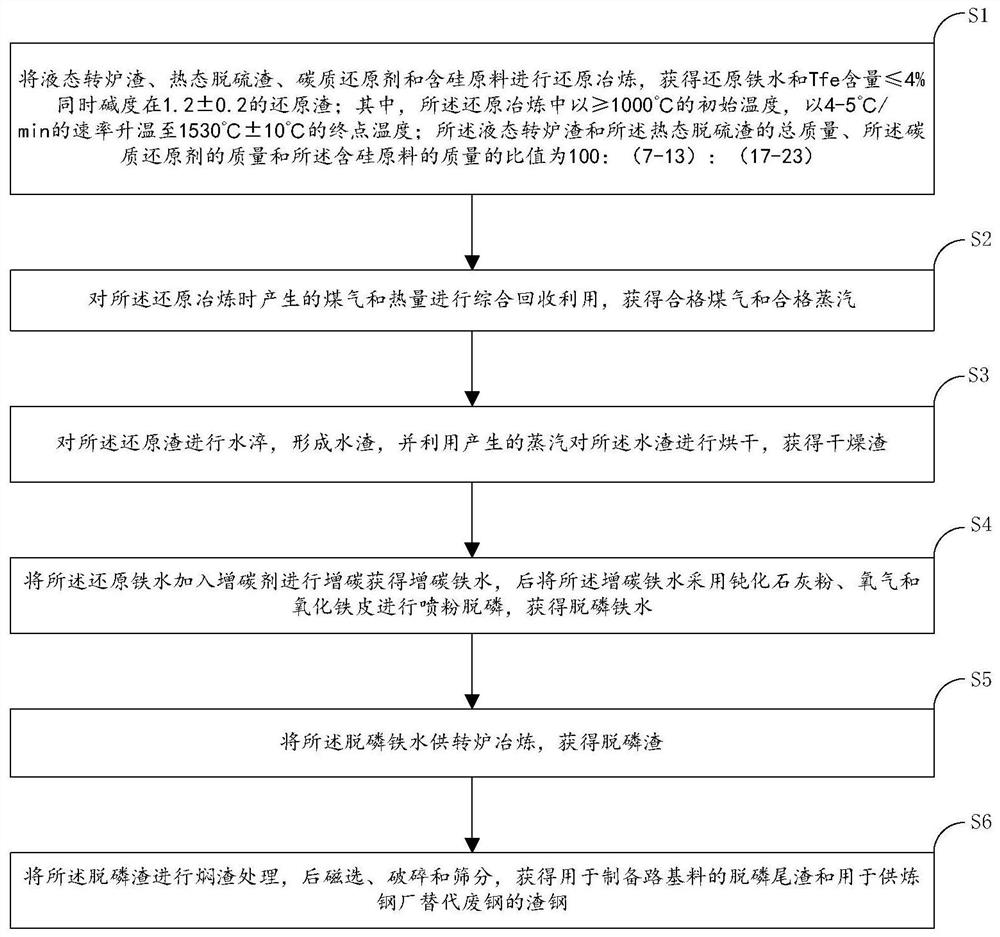

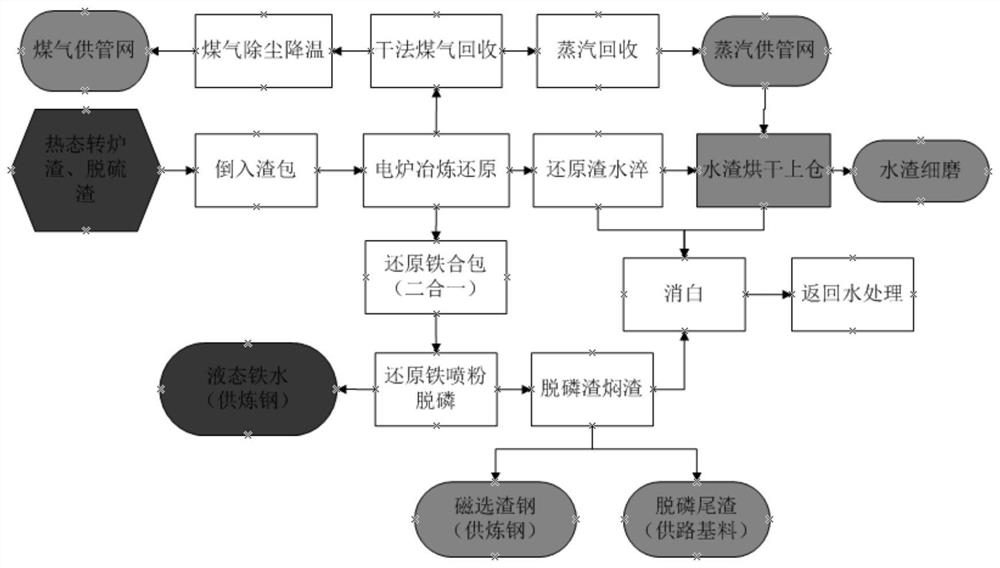

Method used

Image

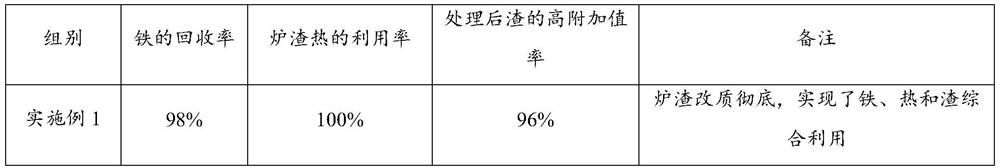

Examples

Embodiment 1

[0119] 1. After the end of converter smelting, pour the high-temperature hot steel slag into the slag tank, and then tap the steel. After tapping, carry out the operation of slag splashing to protect the furnace. After the slag splashing, no slag dumping operation is performed;

[0120] 2. Pour high-temperature hot converter slag into a special slag ladle (built with magnesia-carbon bricks), and then pour hot desulfurization slag into the slag ladle, (basically three furnaces of liquid converter slag and three furnaces of molten iron desulfurization slag , the converter slag is first poured into the slag bag, and then the desulfurization slag is poured into the slag bag), and then the slag bag is hoisted under the electric furnace with a rotatable cover (similar to the electric furnace of the LF furnace) for reduction smelting, and at the same time, 10% of the Carbonaceous reducing agent (coke powder, anthracite, etc.) and 20% silica (or silica, iron-containing tailings, etc.),...

Embodiment 2

[0141] In this embodiment, the liquid converter slag, the hot desulfurization slag, the carbonaceous reducing agent and the silicon-containing raw material are subjected to reduction smelting to obtain reduced molten iron and reduced slag with a Tfe content of ≤4% and an alkalinity of 1; wherein , in the reduction smelting, the initial temperature is 1100°C, and the temperature is raised to the end temperature of 1520°C at a rate of 4°C / min; the total mass of the liquid converter slag and the hot desulfurization slag, the carbonaceous reducing agent The ratio of the mass of the silicon-containing raw material to the mass of the silicon-containing raw material is 100:13:23; other steps are the same as in Example 1.

Embodiment 3

[0143] In this embodiment, the liquid converter slag, the hot desulfurization slag, the carbonaceous reducing agent and the silicon-containing raw material are subjected to reduction smelting to obtain reduced molten iron and reduced slag with Tfe content ≤ 4% and an alkalinity of 1.4; wherein , in the reduction smelting, the initial temperature is 1200°C, and the temperature is raised to the end temperature of 1540°C at a rate of 5°C / min; the total mass of the liquid converter slag and the hot desulfurization slag, the carbonaceous reducing agent The ratio of the mass of the silicon-containing raw material to the mass of the silicon-containing raw material is 100:7:17; other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com