Automatic judging device and automatic judging method

A discriminating device and automatic technology, applied in the direction of measuring devices, adopting optical devices, fiber processing safety devices, etc., can solve the problems of inability to select and classify measurement objects and require computers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

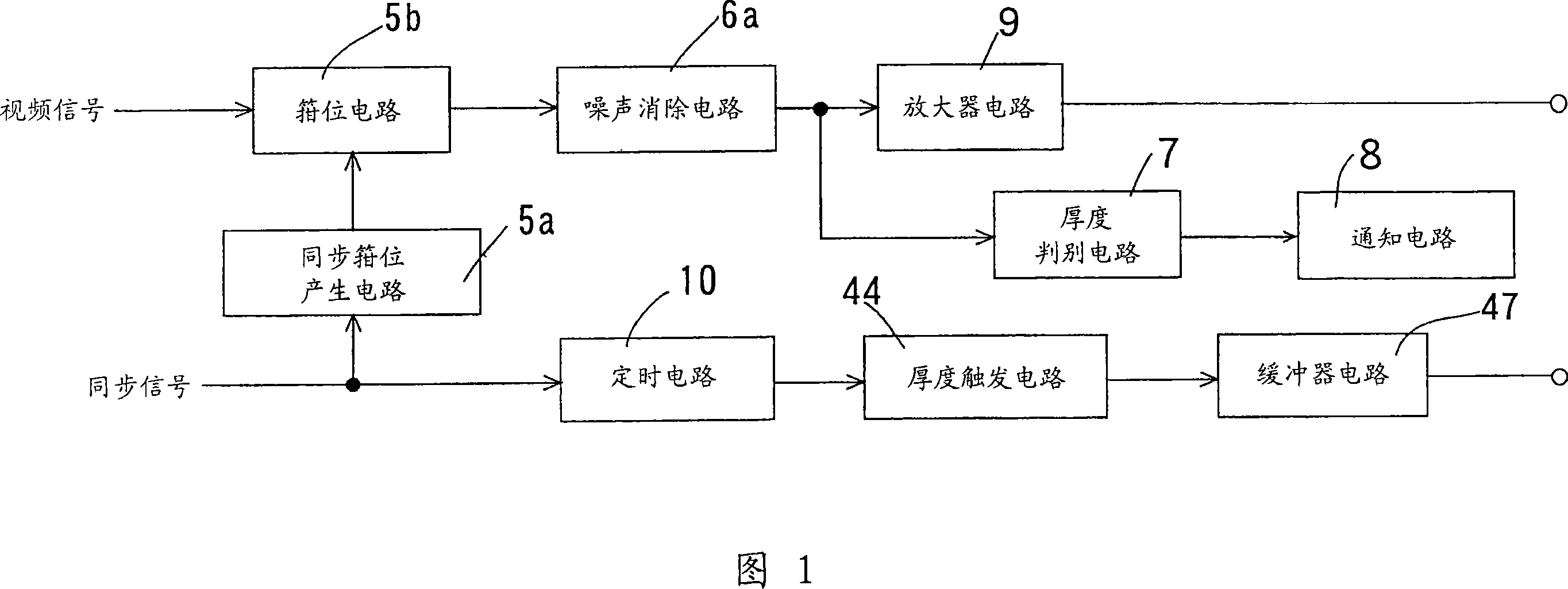

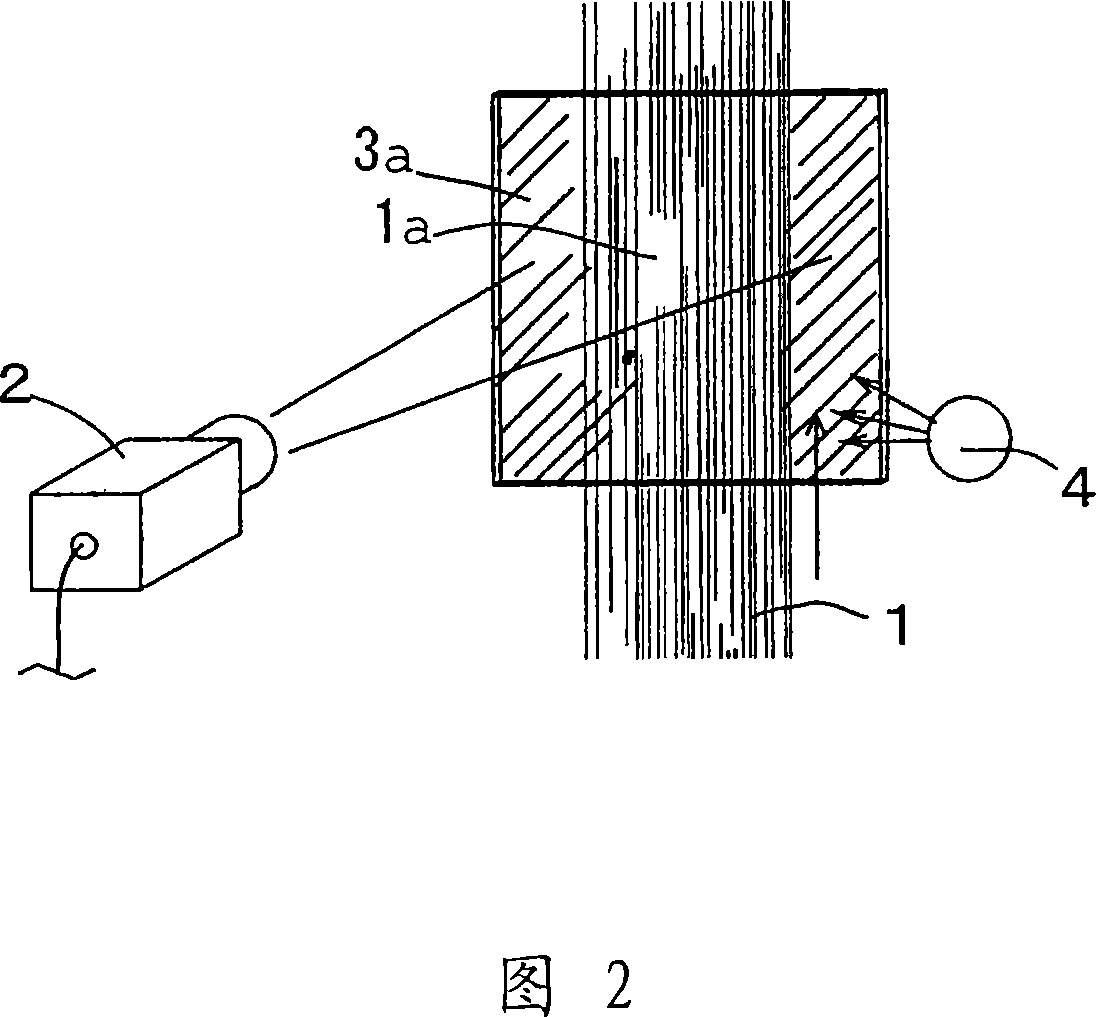

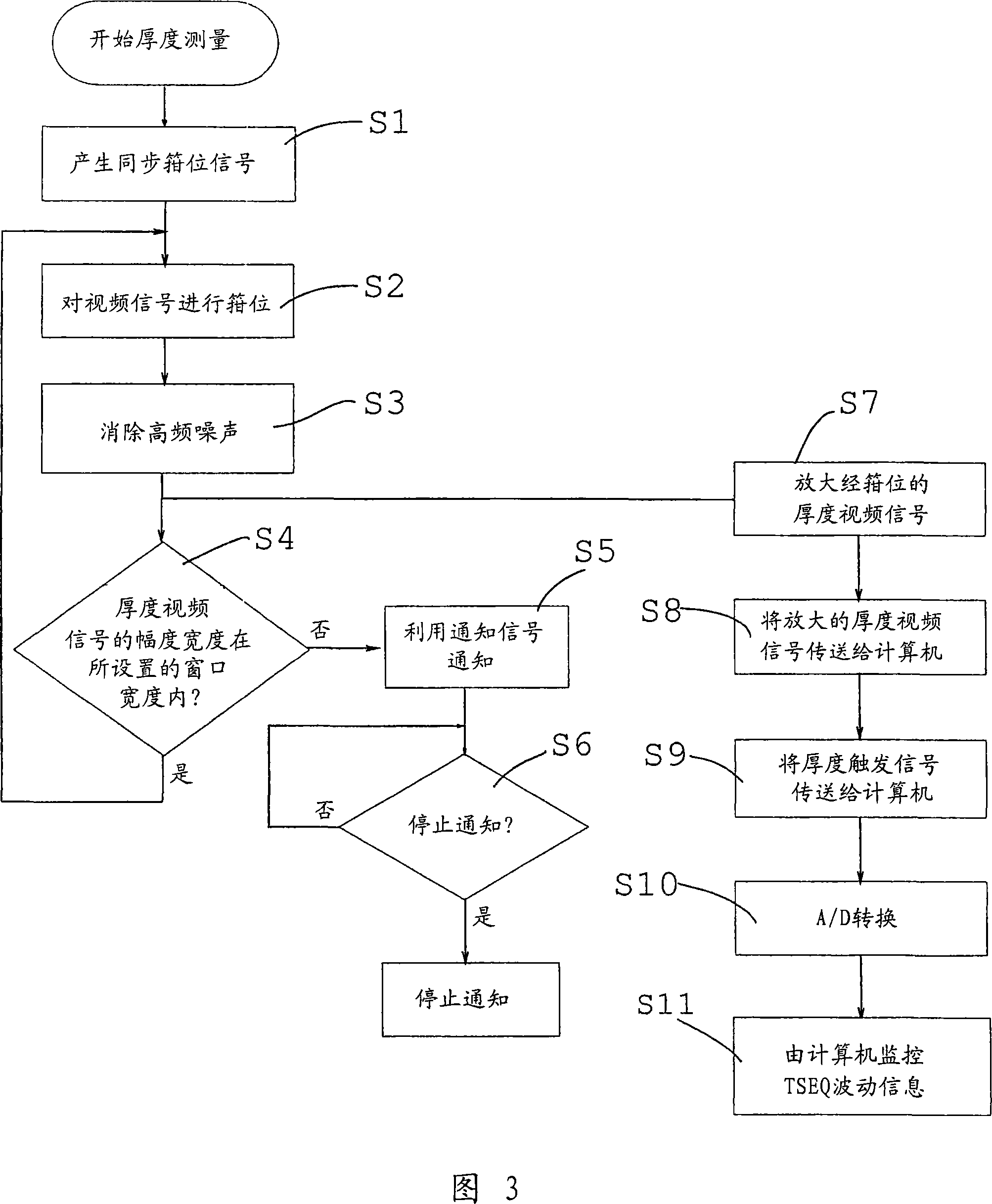

[0052] 1 is a block diagram showing an example of an electrical configuration of a system of the present invention, FIG. 2 is a schematic layout diagram of the system of FIG. 1 , and FIG. 3 is a flowchart for illustrating the operation of the system of FIG. 1 . In this example, the thickness (or non-uniform thickness) of a continuously moving filter tow (ribbon-shaped tow) is detected. The filter tow (or tow band) comprises a plurality of filaments. That is, the filter tow is formed of a plurality of filaments that are bundled, arranged adjacent to each other, and overlapped to form a layer. Therefore, the degree of adjacency or overlap of the filaments fluctuates as the filaments move, and unevenness in thickness of the filter tow tends to produce defective products.

[0053] As shown in Figure 2, on the front side of the filter tow 1 moving continuously from the lower side to the upper side, a line sensor (imaging device) 2 is arranged at a predetermined viewing angle, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com