Method and device for detecting foreign matter in a moving solid elongated test object

An object and solid technology, which is used in the field of detecting impurities and equipment in solid and slender objects to be tested in motion. It can solve the problems of inability to detect impurities, high humidity sensitivity, and inability to detect impurities hidden inside the object to be tested, etc. problem, achieve the effect of saving space and simplifying the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

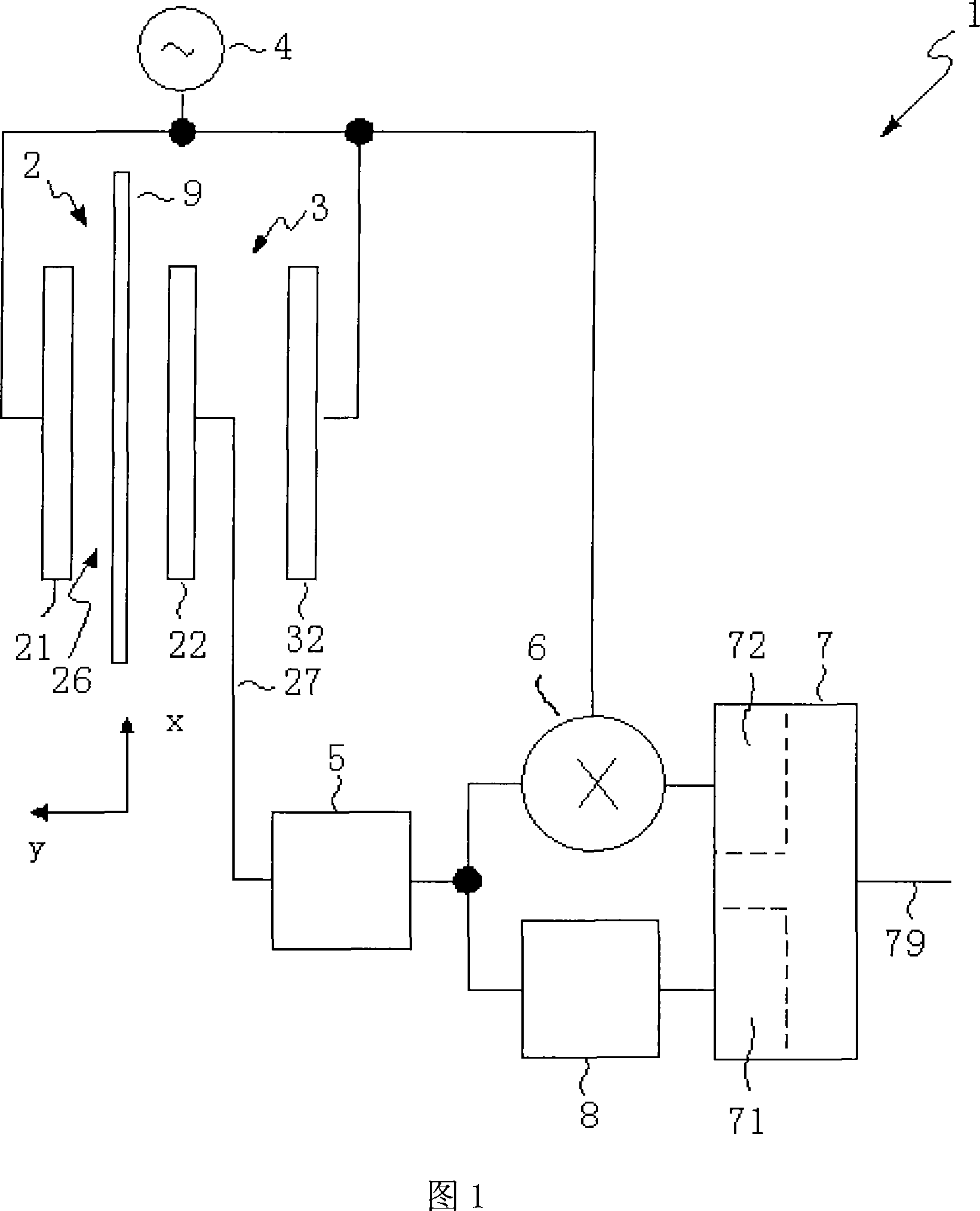

[0021] In FIG. 1 an electrical connection diagram of a device 1 according to the invention is shown. The device 1 includes a measuring capacitance 2 . Thus, in this embodiment a planar bipolar plate capacitor is included having a first requisite planar capacitive plate 21 and a second requisite planar capacitive plate 22 . The capacitive plates 21, 22 are both about 0.8 mm thick, are made of eg brass, and are coated with eg nickel to achieve higher wear resistance. The two capacitive plates 21 , 22 are separated from each other by about 1-3 mm, preferably by an air gap about 1.5-2.0 mm thick, which forms a passage 26 for the solid, elongated object 9 to be tested. The object 9 to be tested may be yarn or the like. Preferably, the test object 9 is moved through said passage 26 along the longitudinal axis x.

[0022] It is well known that textile materials such as yarn 9 and other materials can be electrostatically charged. This charging process can be achieved, for example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com