Device for cleaning and opening textile material, especially cotton at clearer, carding machine

A technology of yarn clearer and carding machine, which is applied in the field of advanced devices, can solve problems such as difficulty in changing adjustment parameters, different content of domains or local concentration or even adaptation of a single individual, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

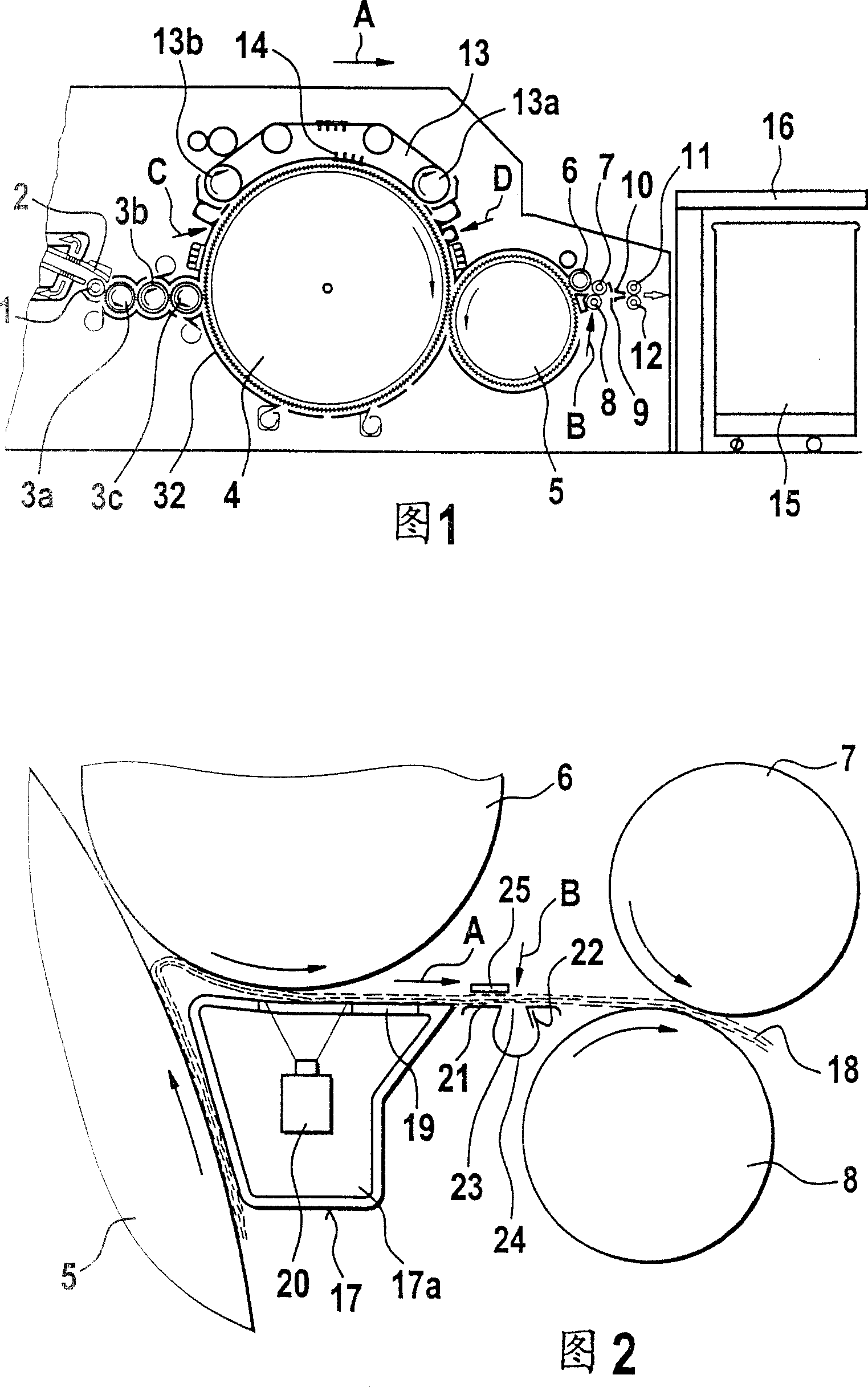

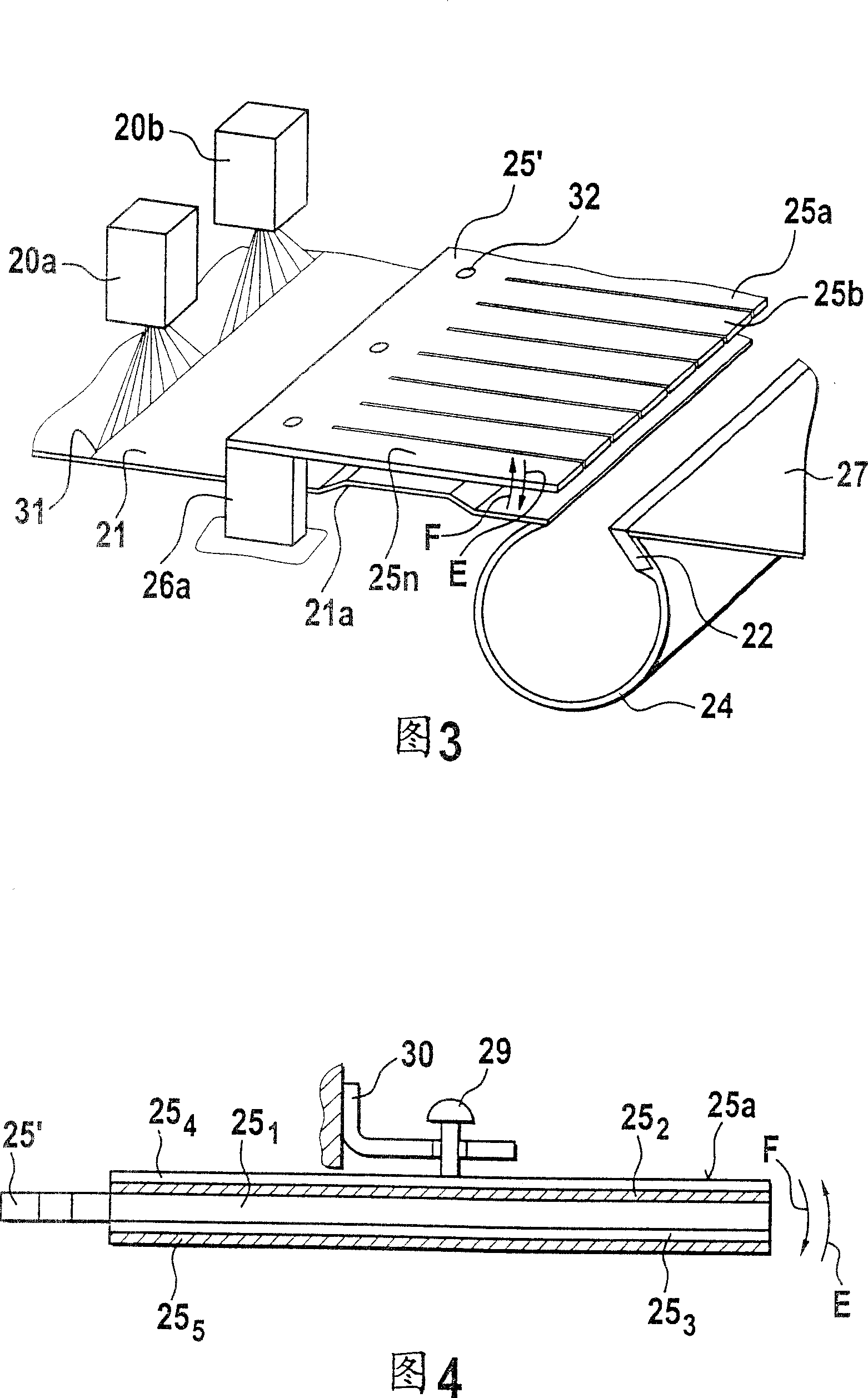

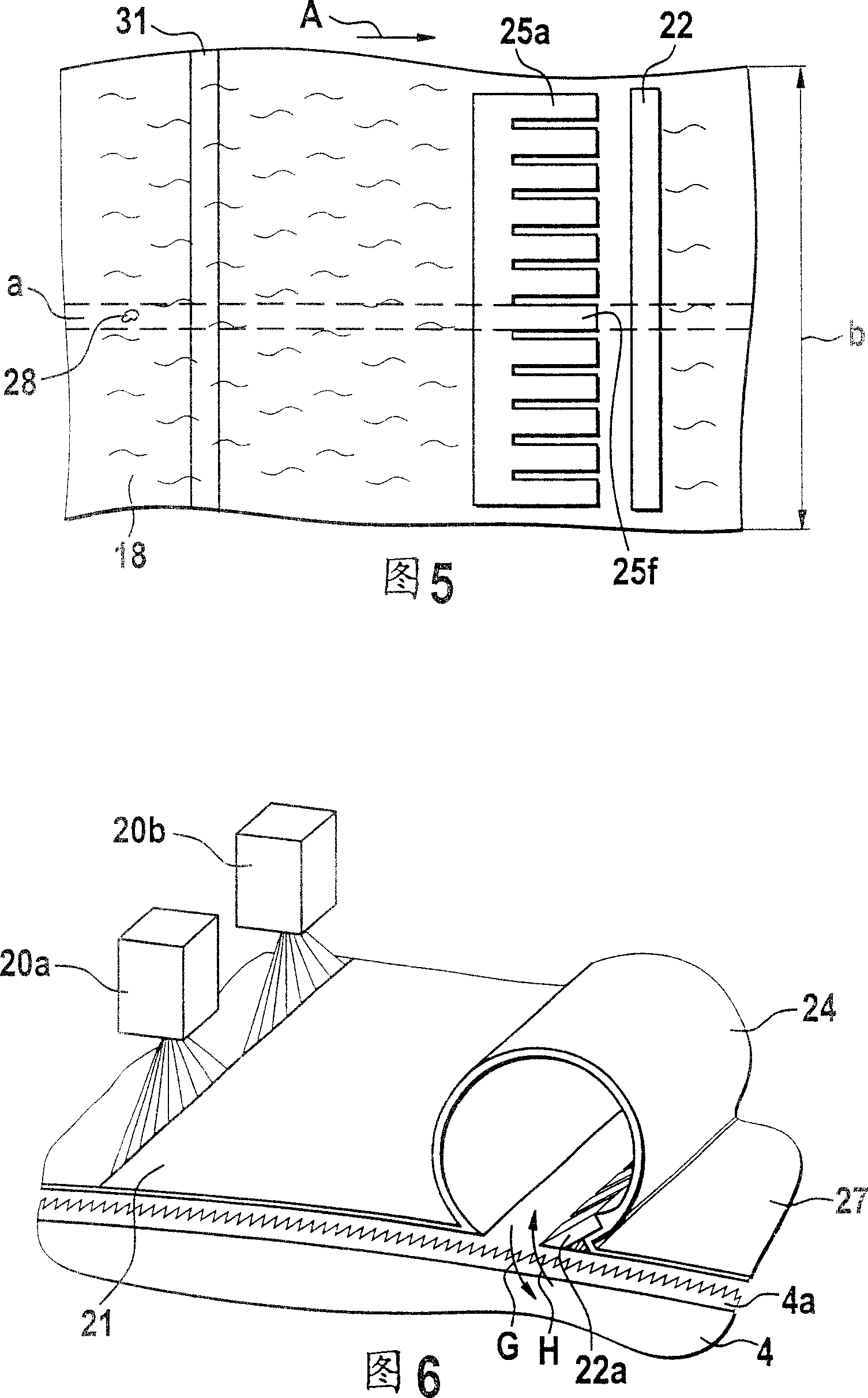

[0017] Fig. 1 shows a carding machine, such as Truetzschler DK903 high-efficiency carding machine, has a feed roller 1, curtain feed table 2, licker-in roller 3a, 3b, 3c, carding cylinder 4, doffer cylinder 5, stripping roller 6, removing Miscellaneous crushing rollers 7, 8, nonwoven guide elements 9, web collection bell 10, output rollers 11, 12, revolving flat 13 with flat bar 14, can 15 and coiler 16. The direction of rotation of the rollers is indicated by curved arrows. Use A to indicate the working direction. Below the stripping roller 6 there is a support and guide body 17 for the fibrous material (fibrous web) 18 . Designated by B is the area in which the opened fibrous material is transferred from the support and guide body 17 into the nip between the decontamination and crushing rollers 7 , 8 . A first structure of the present invention is provided in area B (see FIGS. 2 to 4 ). Another configuration according to the invention is provided in the regions C and D as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com