Device for detecting and separating impurity in or between fiber materials on spinning preparation machine

A technology for separating fibers and preparing machines, which is applied in the direction of analyzing materials, fiber processing, fiber feeding, etc. It can solve the problems of reducing separator efficiency, increasing air pressure, and complicated equipment, and achieves the effect of saving space, avoiding pollution, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

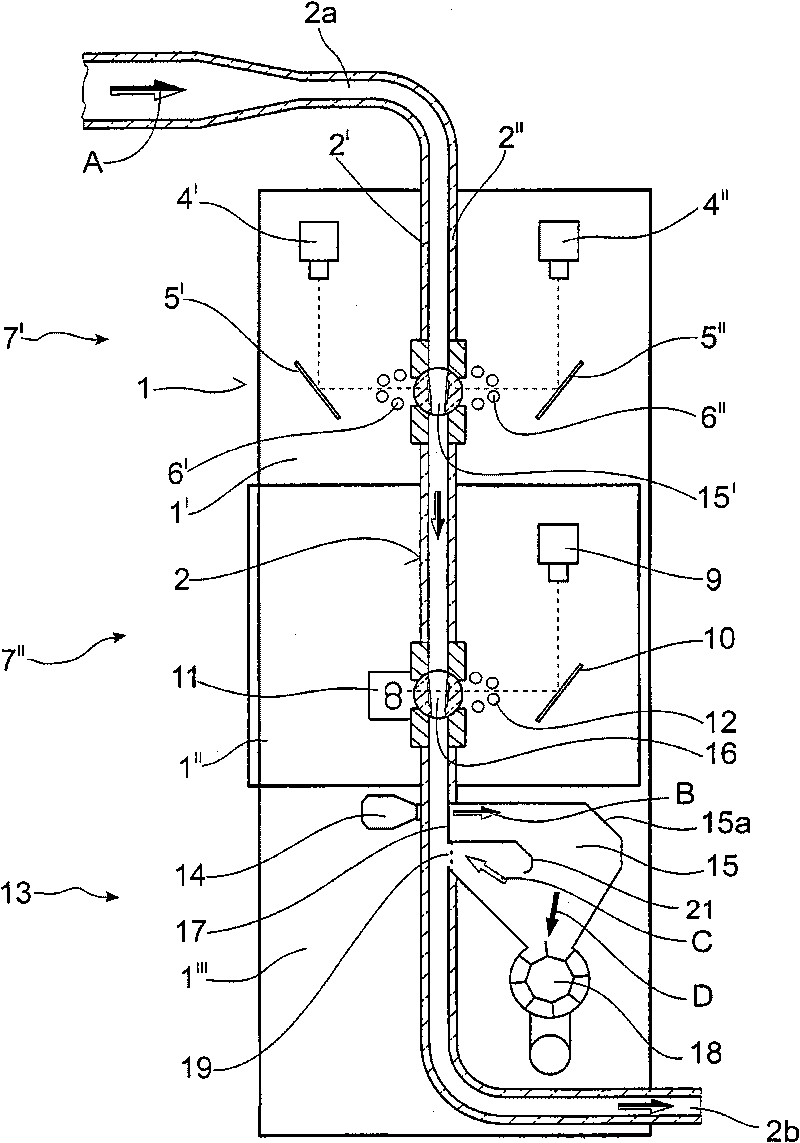

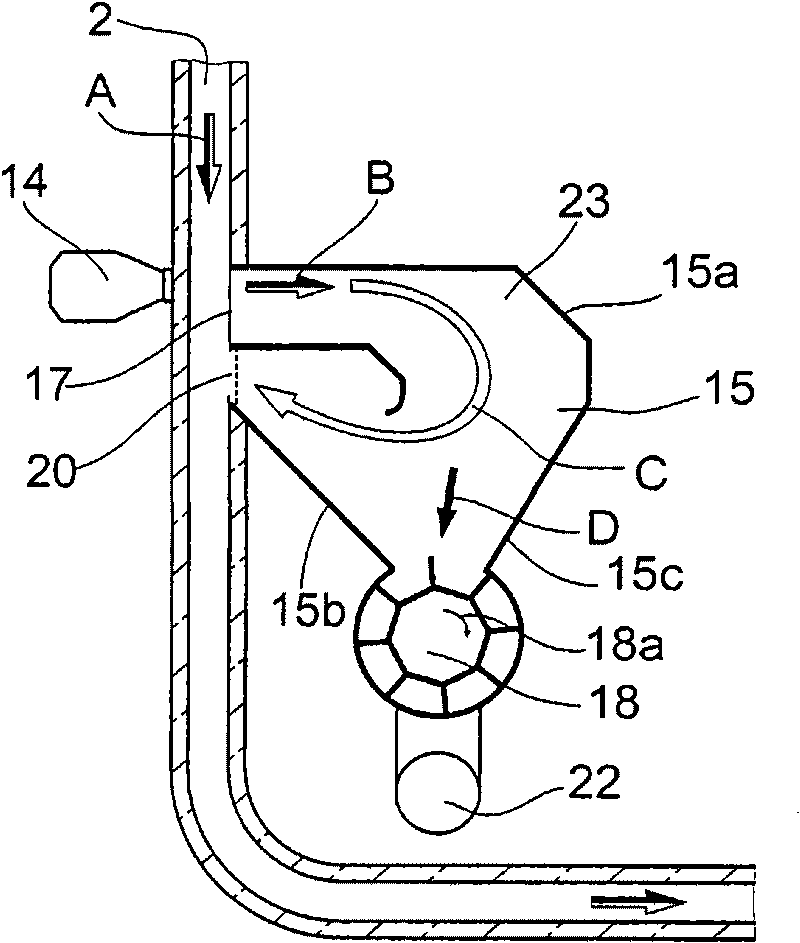

[0029] Such as figure 1 As shown, a vertical channel 2 is arranged inside the frame 1, and the parallel side walls 2', 2" opposite to each other are at least partially configured as transparent panels, and the outsides of the side walls 2', 2" are connected with lighting devices.

[0030] The first detection device 3 comprises two CCD cameras 4', 4" (line scan cameras), which act indirectly on the glass channel 15' via two mirrors 5' and 5" inclined at an angle, respectively. . The optical planes are arranged slightly offset from each other. On the side wall of the tunnel 2 opposite the camera 4' an illumination system 6'' is arranged, and on the side wall of the tunnel 2 opposite the camera 4'' an illumination system 6' is arranged. In this way, the material in the glass channel 15' is detected from both sides by the two cameras 4', 4".

[0031] The frame 1' containing the glass channel 15', the camera 4', 4", the tilting mirror 5', 5" and the lighting system 6', 6' consti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com