Disk plucker

A disc catching machine and cotton hopper technology, which is applied in the directions of unpacking machines, textile and papermaking, fiber processing, etc. Efficiency and gripping quality, increased gripping speed and gripping quality, effect of increased contact area and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

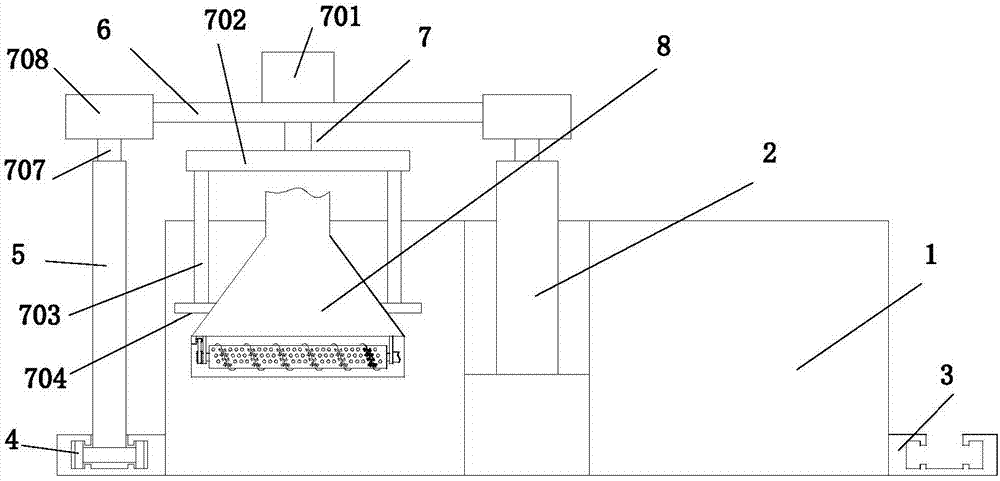

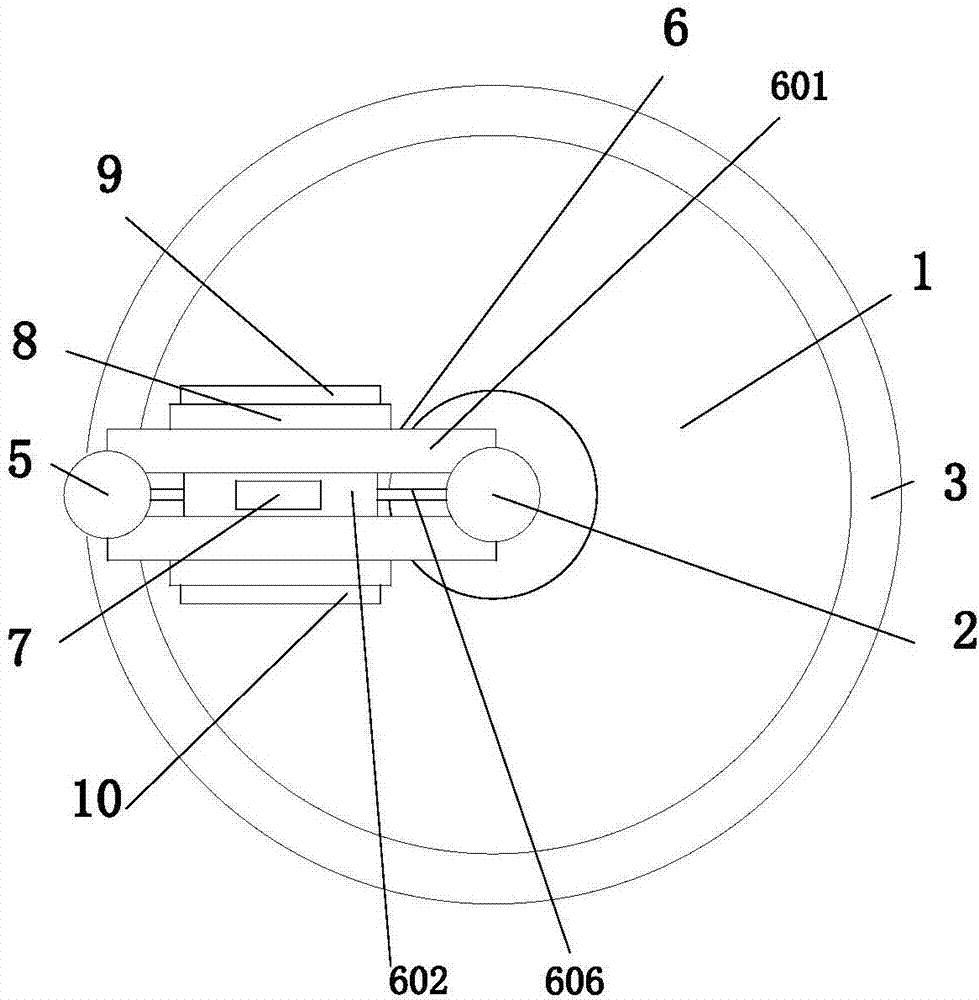

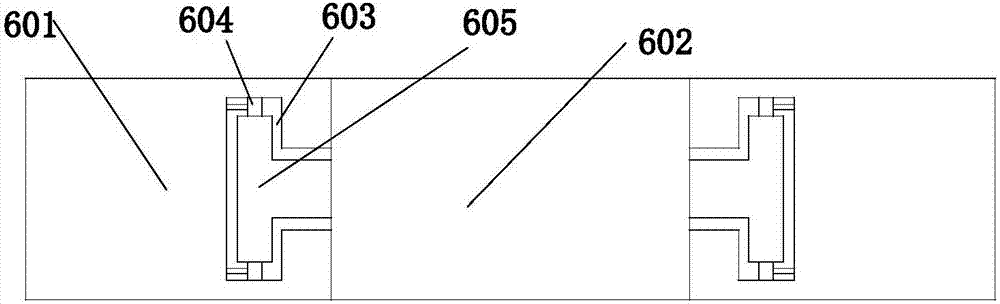

[0030] Example. Disc bale bale machine, constituted as Figure 1 to Figure 14 As shown, there is a silo 1 with a ring structure. The center of the silo 1 is provided with a rotating column 2. The outer wall of the silo 1 is provided with a circular guide rail 3. The column 5, the driving column 5 and the rotating column 2 are provided with a supporting sliding device 6, and the supporting sliding device 6 is provided with a lifting device 7, and the bottom of the lifting device 7 is provided with a cotton collection device 8, and the bottom of the cotton collection device 8 is provided with a removal device. miscellaneous device 9 and humidifying device 10; the humidifying device 10 is connected with a controller 11, and the controller 11 is connected with the driving trolley 4, the supporting slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com