Apparatus in spinning preparation for separating foreign objects at a high-speed roll for opening or doffing fibre material

A fiber raw material and roller technology, applied in fiber processing, fiber processing safety devices, fiber feeding, etc., can solve the problems of operation impact, large space, inconvenience, etc., and achieve fast maintenance, accurate location, and small installation space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

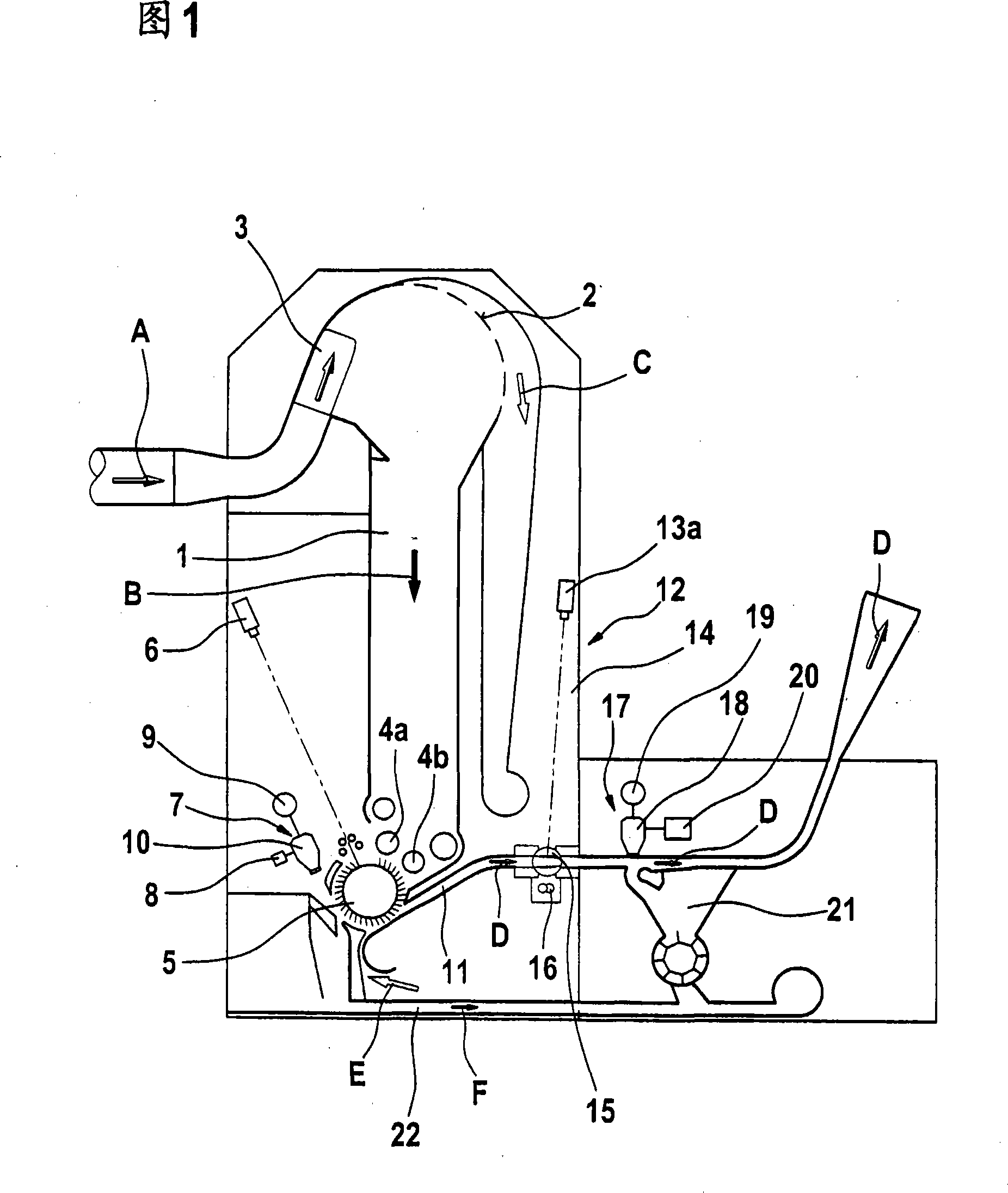

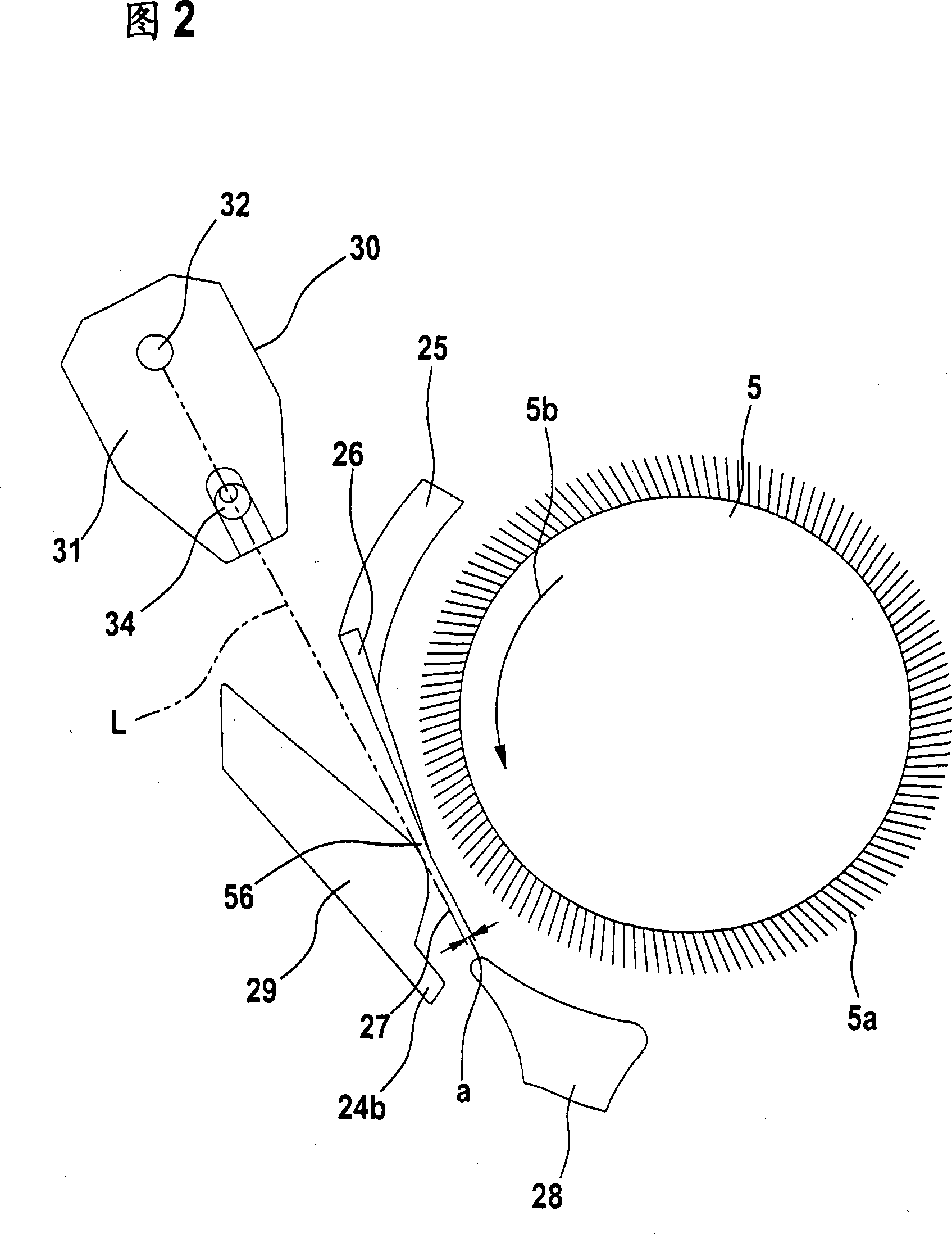

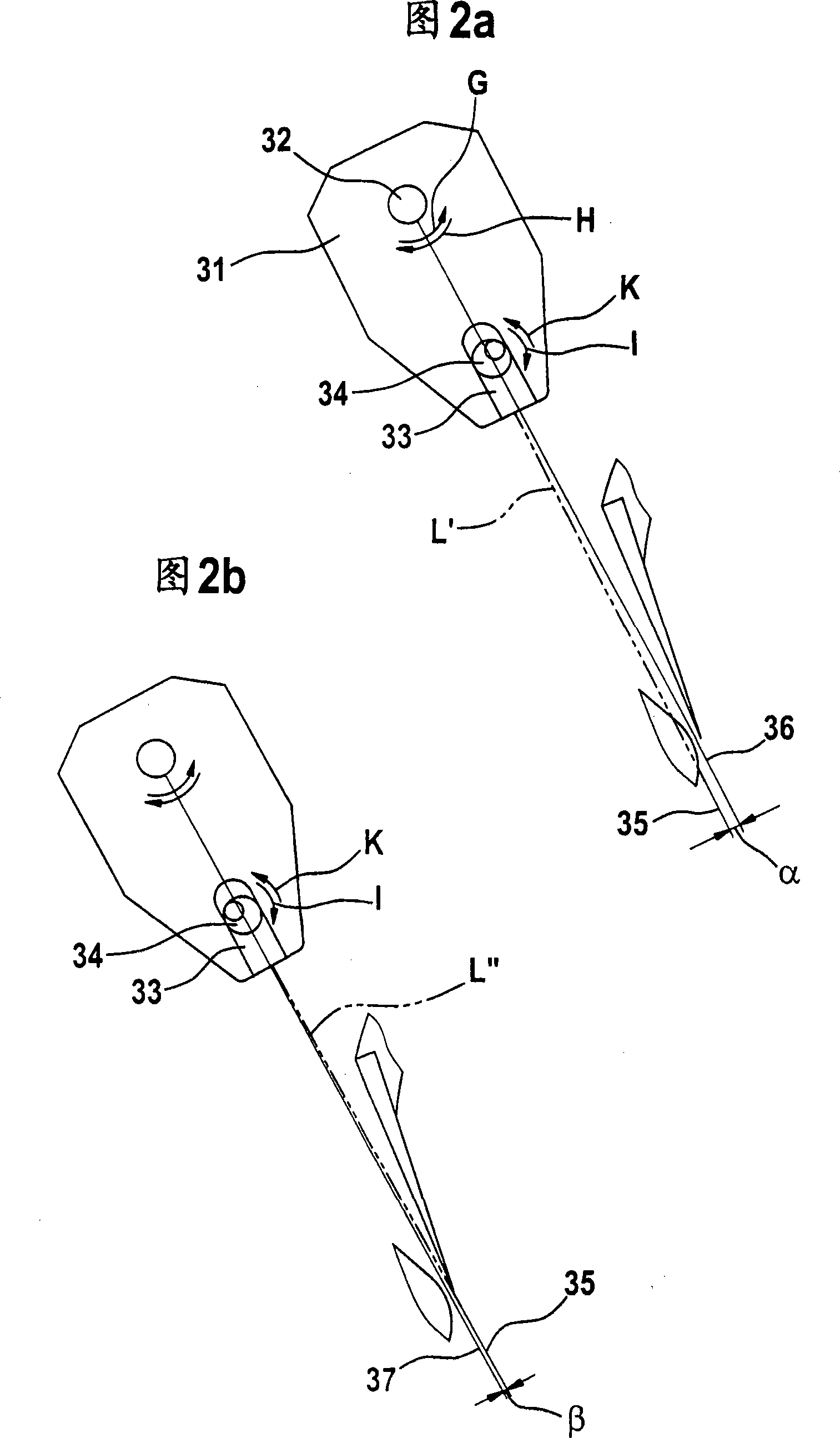

[0026] Referring to Figure 1, in a device for detecting and separating foreign matter, such as the Trützschler foreign matter separator SECUROMAT SP-F2, the upper inlet of the feed tank 1 has a device for the pneumatic supply of the fiber-air flow A, which consists of: Fibrous raw material delivery fan (not shown), is used for separating (expelling) fibrous raw material B and air C by air suction fixed air-permeable surface 2; And has the air flow guiding device 3 of movable element; The fiber raw material is reversibly guided back and forth laterally on the air-permeable surface 2, and then impacted, the fiber raw material falls from the air-permeable surface 2 and enters the feed trough 1 downwards substantially due to the force of gravity. The slow rollers 4a, 4b have a double role: they act as delivery rollers for removing the fiber stock B out of the feed chute 1 and at the same time as feed rollers for feeding the fiber stock B to the high speed opening roller 5 . The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com