Light emitting diode arrays with improved light extraction

a technology of light extraction and led arrays, applied in the direction of discharge tubes, luminescnet screens, identification means, etc., can solve the problems of significant heat generated by dense concentrations of leds, illumination efficiency, and self-heating by absorption, and achieve the effect of improving illumination efficiency and reducing thermal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This description is divided into two parts. Part I describes the structure and features of light emitting diodes (LEDs) packaged in an array for high illumination efficiency in accordance with the invention and illustrate exemplary embodiments. Part II provides further details of the LTCC-M packaging technology as applicable to LED arrays.

I. LEDs Packaged for High Illumination Efficiency

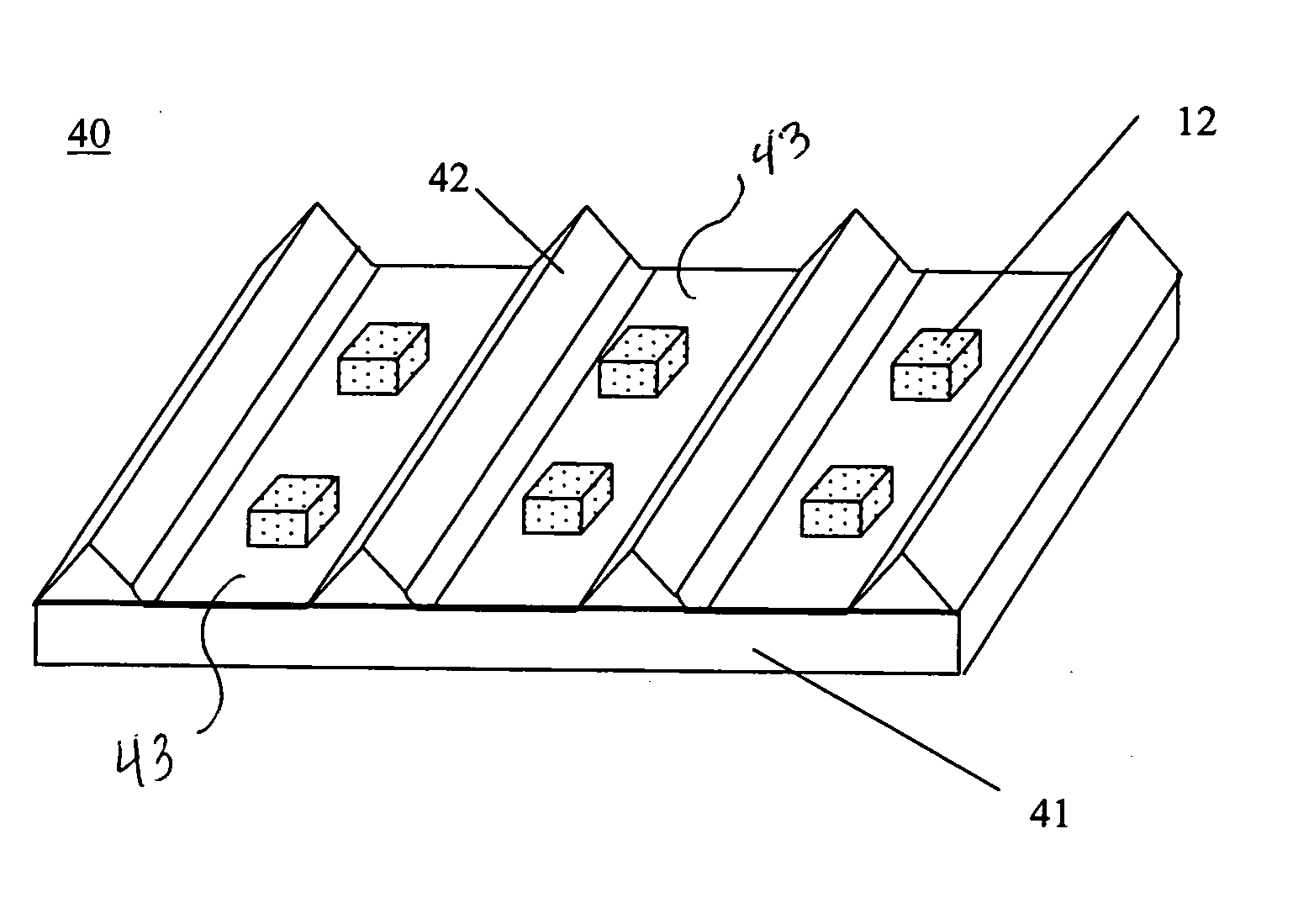

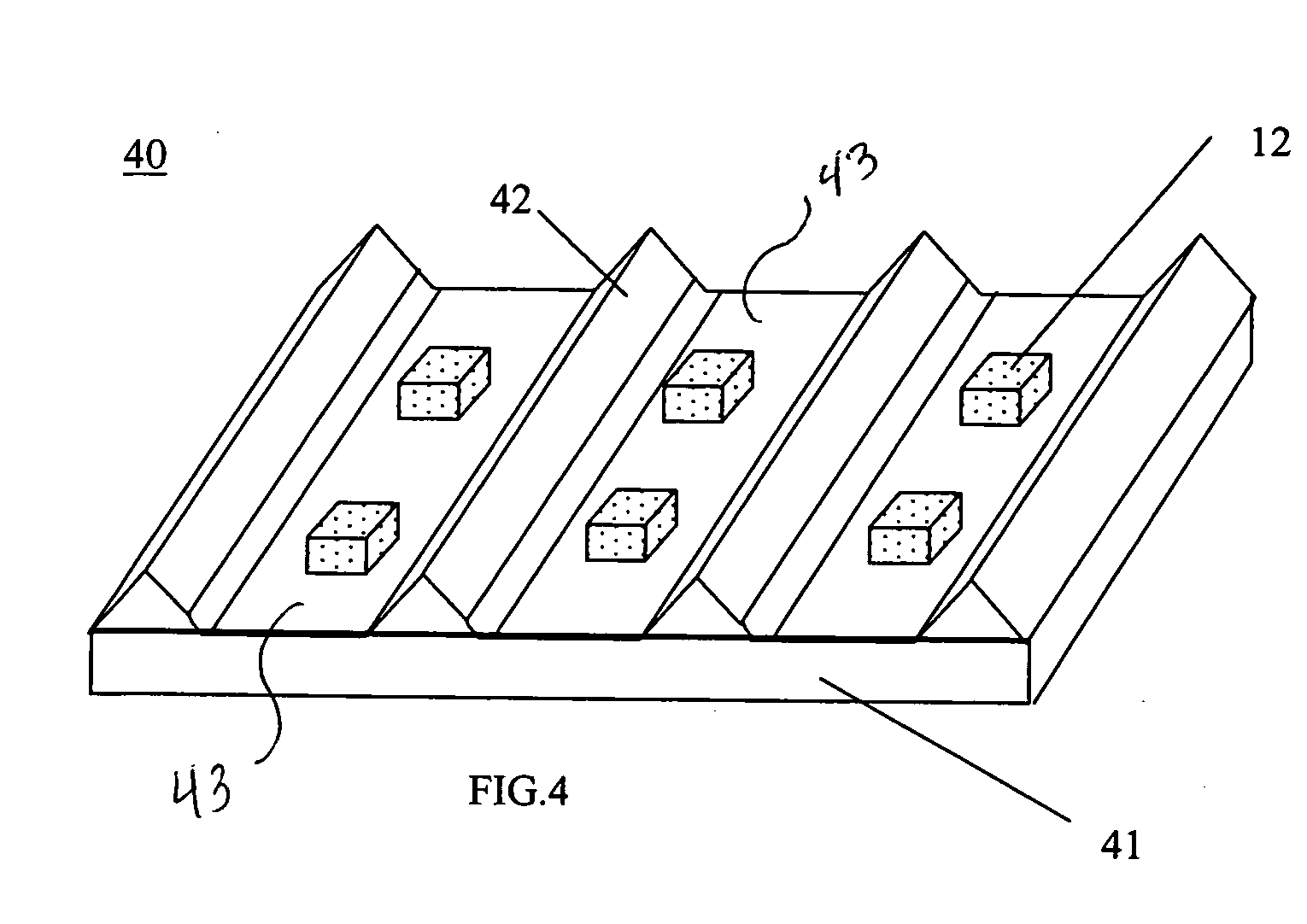

[0017]FIG. 4 illustrates, a tapered barrier reflector 40 fabricated as a periodic array of troughs 41 and tapered reflective ridges 42. This accordion-like structure is a particularly cost effective to manufacture. Metal reflective material can be folded in an accordion-like manner to form the tapered reflective barriers 42. LED dies 12 can be affixed in the troughs 43 between reflective barriers 42.

[0018] The barrier reflector 40 can provide a connection to the anode or cathode of LED dies 12. The barrier 40 also serves a thermal cooling function. Heat from the LED die 12 can be channeled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com