Power supply for light emitting diode array

a technology of light-emitting diodes and power supplies, applied in emergency power supply arrangements, process and machine control, instruments, etc., can solve problems such as poor power factor of highly reactive power supplies, poor leakage current waveforms of input current, and use of questionable led signals. , to achieve the effect of eliminating leakage current problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

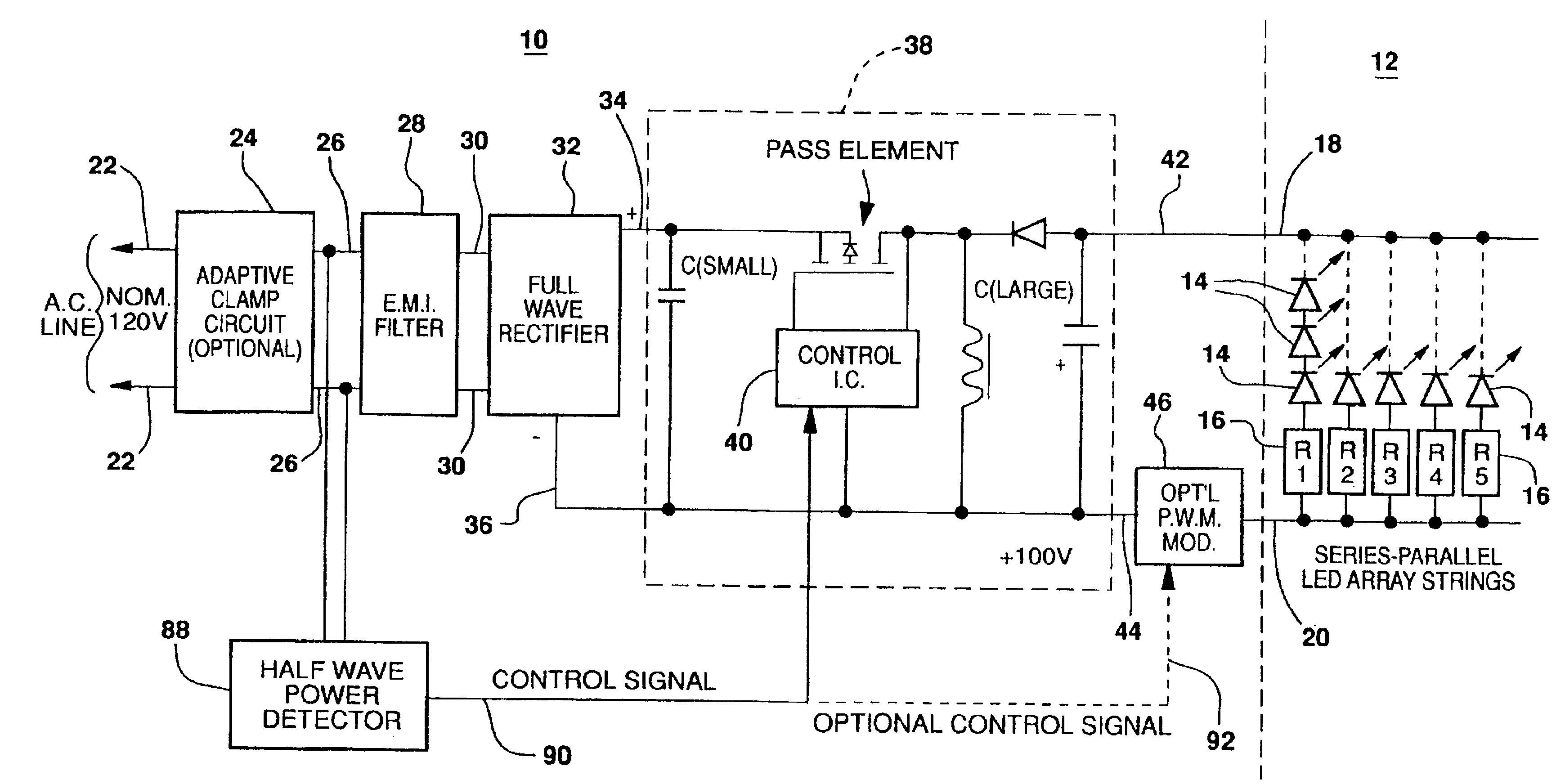

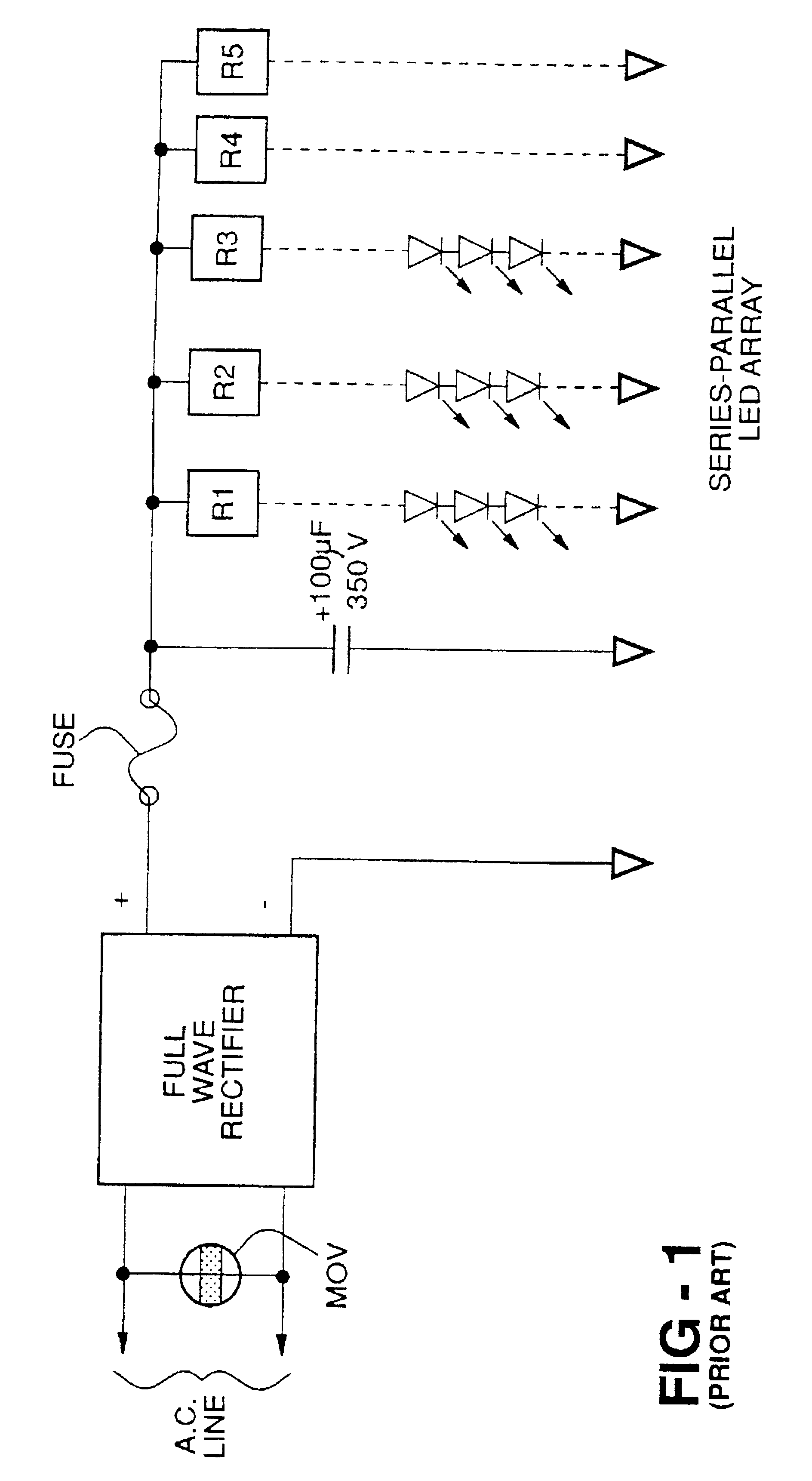

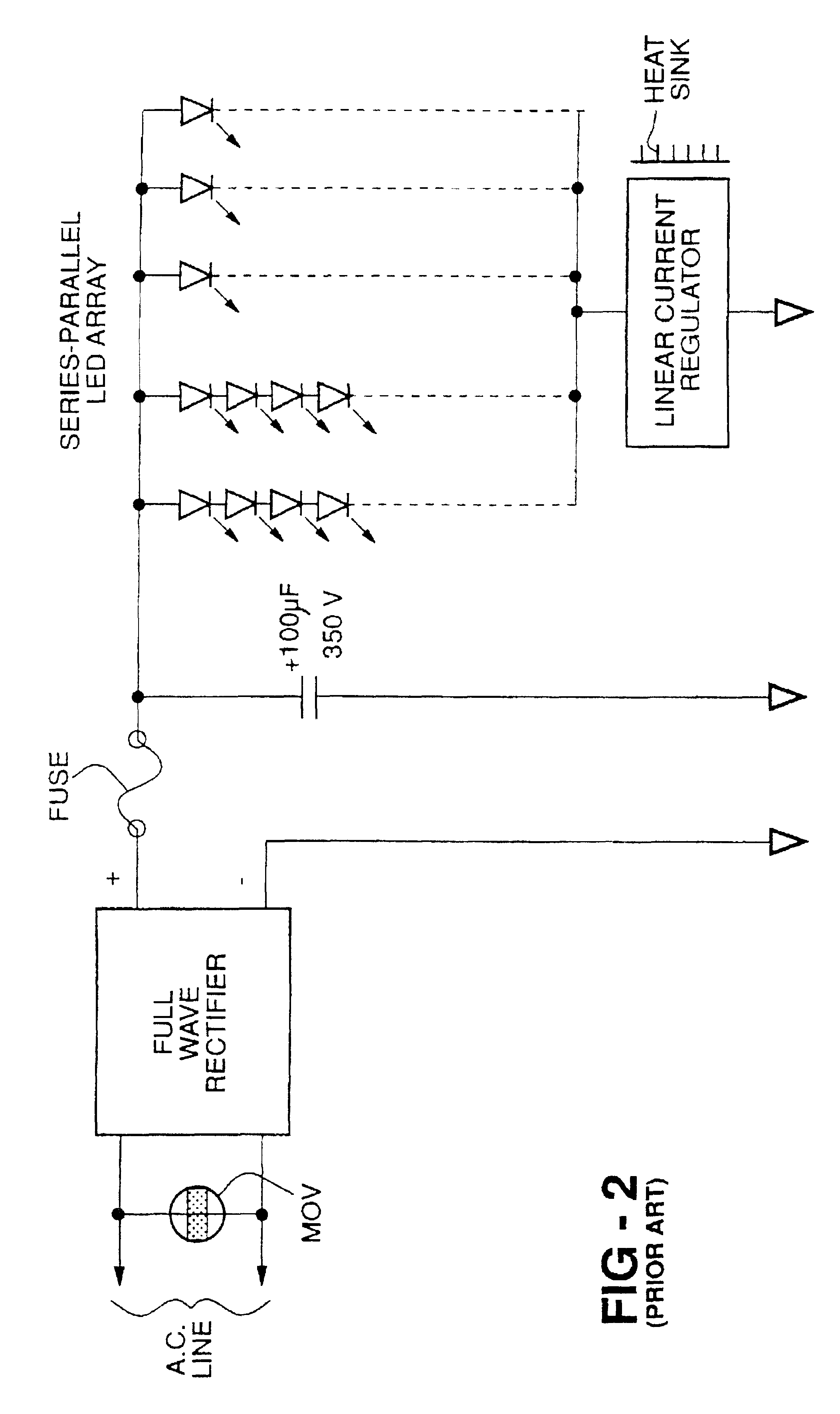

[0031]As noted above, the elementary power supplies that are currently used for powering LED array signals do not meet current standards for efficiency, reliability and performance. The unregulated, resistively ballasted power supply shown in the FIG. 1 does not isolate the LEDs from line voltage variations, and exhibits a poor power factor because of the rectifier and large capacitor. The commercially produced current regulated LED power supply, which is shown in the FIG. 2, does provide much better LED light intensity regulation with input voltage variation. However, the use of a linear, dissipative (heat producing) regulator presents problems. LEDs are thermally sensitive devices which degrade quickly at elevated temperatures. Since most power supplies for LED signals are part of, or are attached to the LED array, heat rise from the linear regulator can be deleterious. Furthermore, the traditional rectifier-capacitor circuit does not produce a satisfactory power factor.

[0032]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com