Thin film transistor in liquid crystal display and manufacturing method thereof

A technology of liquid crystal display devices and thin film transistors, applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of leakage current and large coupling capacitance, and achieve the elimination of leakage current, increase in width, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

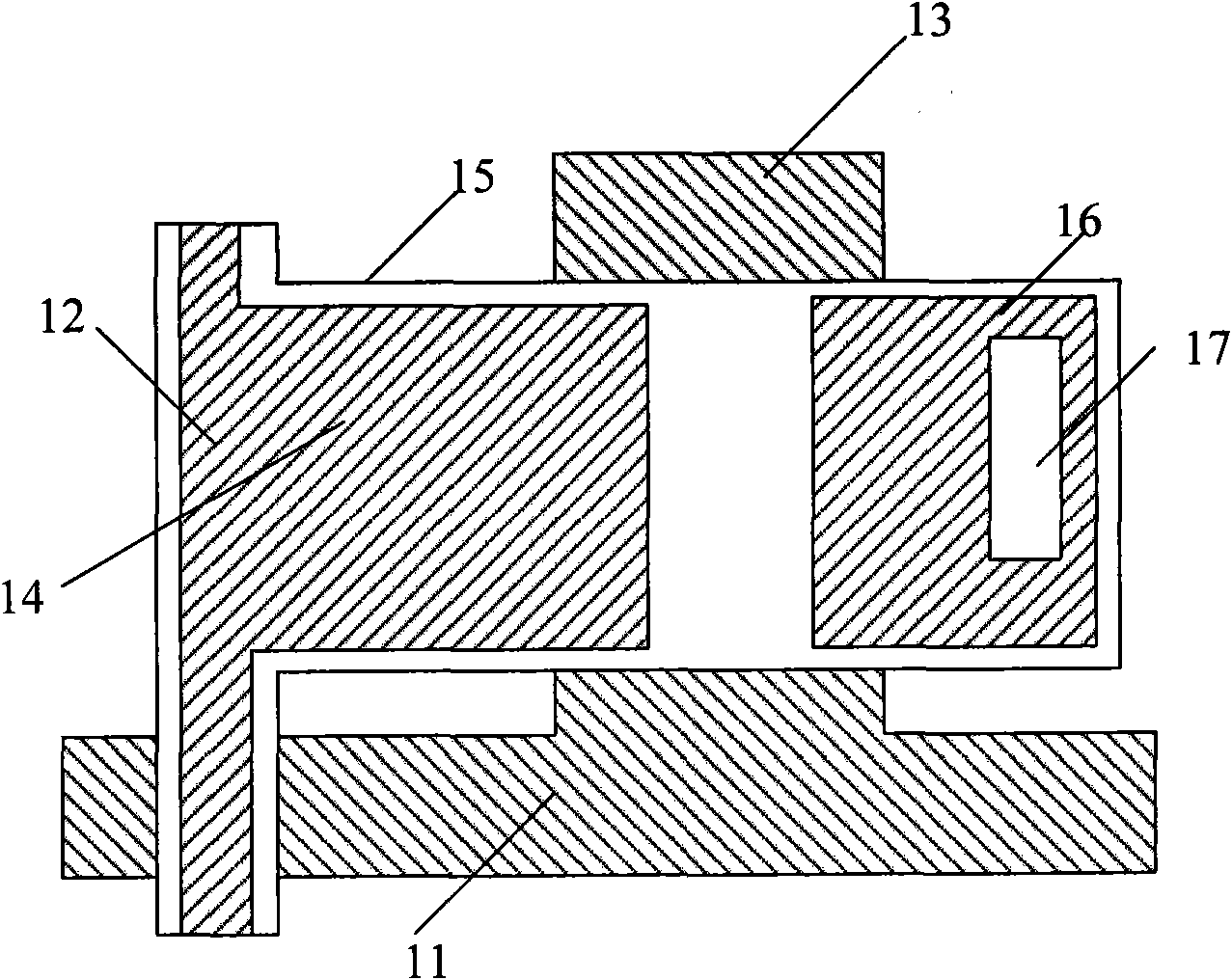

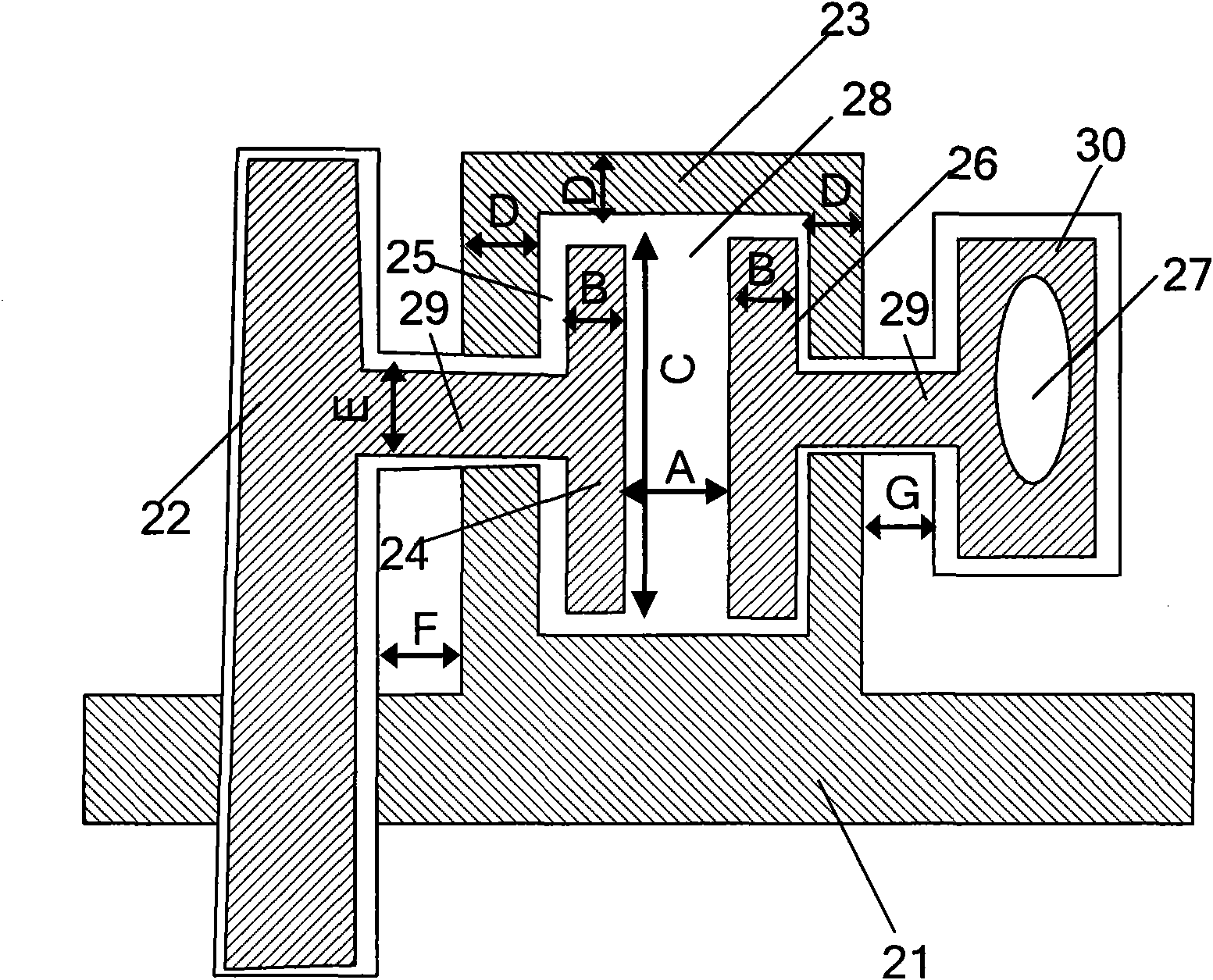

[0036] image 3 It is a schematic diagram of a thin film transistor of the present invention. like image 3 As shown, the liquid crystal display device of the present invention includes a plurality of display units, each display unit includes a scanning line 21, a data line 22, a pixel electrode 30 and a thin film transistor, and the thin film transistor is placed vertically, wherein the thin film transistor includes: A grid 23, which is connected to the scanning line 21; a drain 24, which is connected to the data line 22; and a source 26, which is directly or connected to the pixel electrode (not shown) through a contact hole 27, in the source A channel 28 is formed between the electrode 26 and the drain 24 . The source electrode 26 and the drain electrode 24 are formed on an active layer 25, and the area of the source electrode 26 and the drain electrode 24 protruding from the gate electrode 23 is reduced, specifically, the source electrode 26, the drain electrode 24 and...

Embodiment 2

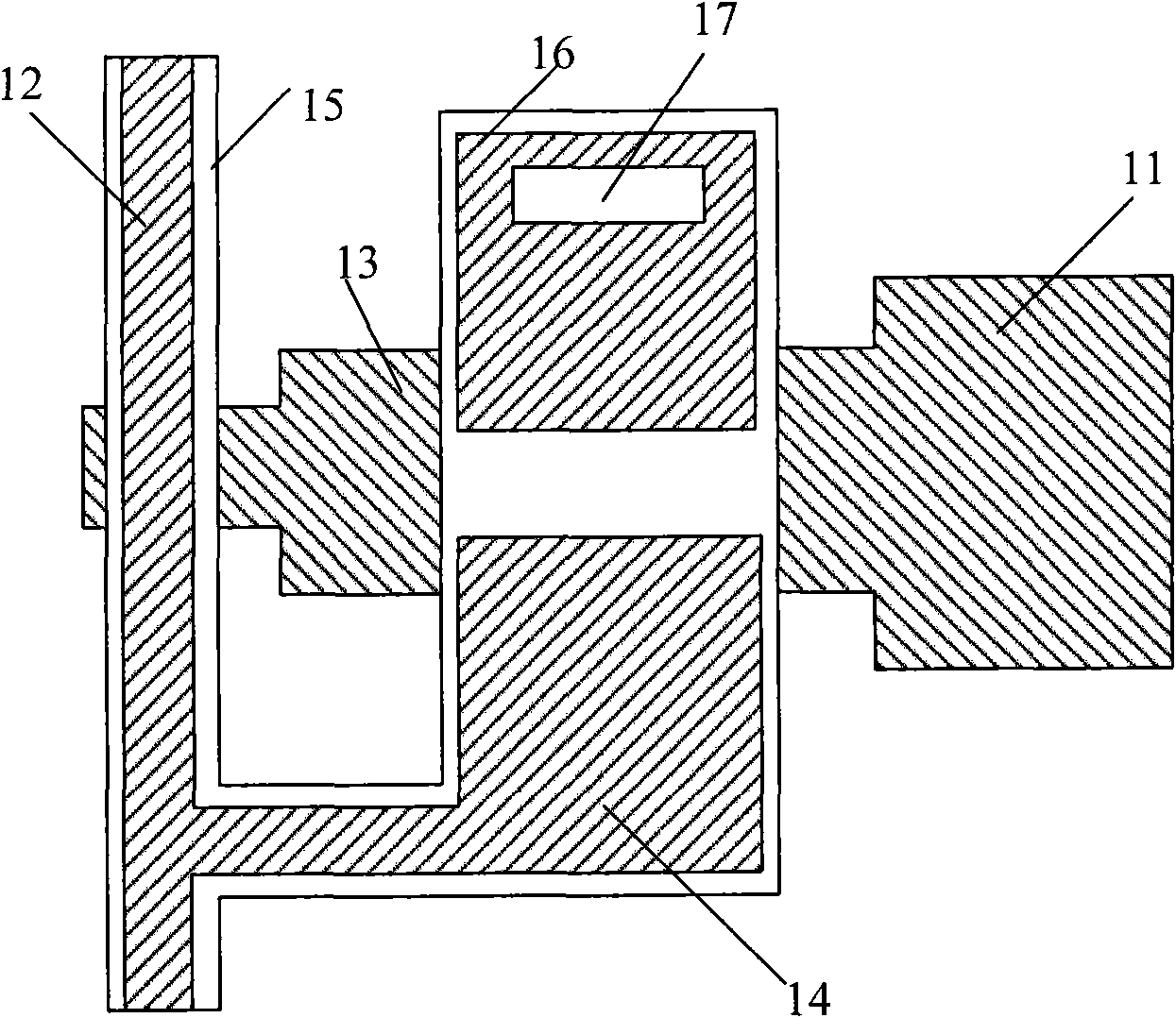

[0044] Figure 4 It is a schematic diagram of the second thin film transistor of the present invention. like Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the main difference is that the thin film transistors are placed laterally, and the length direction of the gate 23 and the source are parallel to the scanning line 21 . The width B' of the gate 23 is 27um, and the channel 28 partially protrudes from the gate 23. The width direction of the source electrode 26 and the drain electrode 24 is perpendicular to the scan line 21 .

Embodiment 3

[0046] Figure 5 It is a schematic diagram of the third thin film transistor of the present invention. like Figure 5 As shown, this embodiment is basically the same as Embodiment 2, the main difference is that: the length of the channel 28 is smaller than the width of the gate 23 , and the channel 28 is located inside the gate 23 . According to the maximum interlayer offset between the data line and the scan line, the distance J of the gate 23 beyond the channel 28 is set to 3um, and the length H of the channel 28 is set to 27um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com