A multi-source integrated color-tunable light-emitting element and its preparation method

A technology for light-emitting components and colors, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of difficult wavelength control, difficult light color mixing to achieve ideal effects, and high control requirements for quantum dot growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

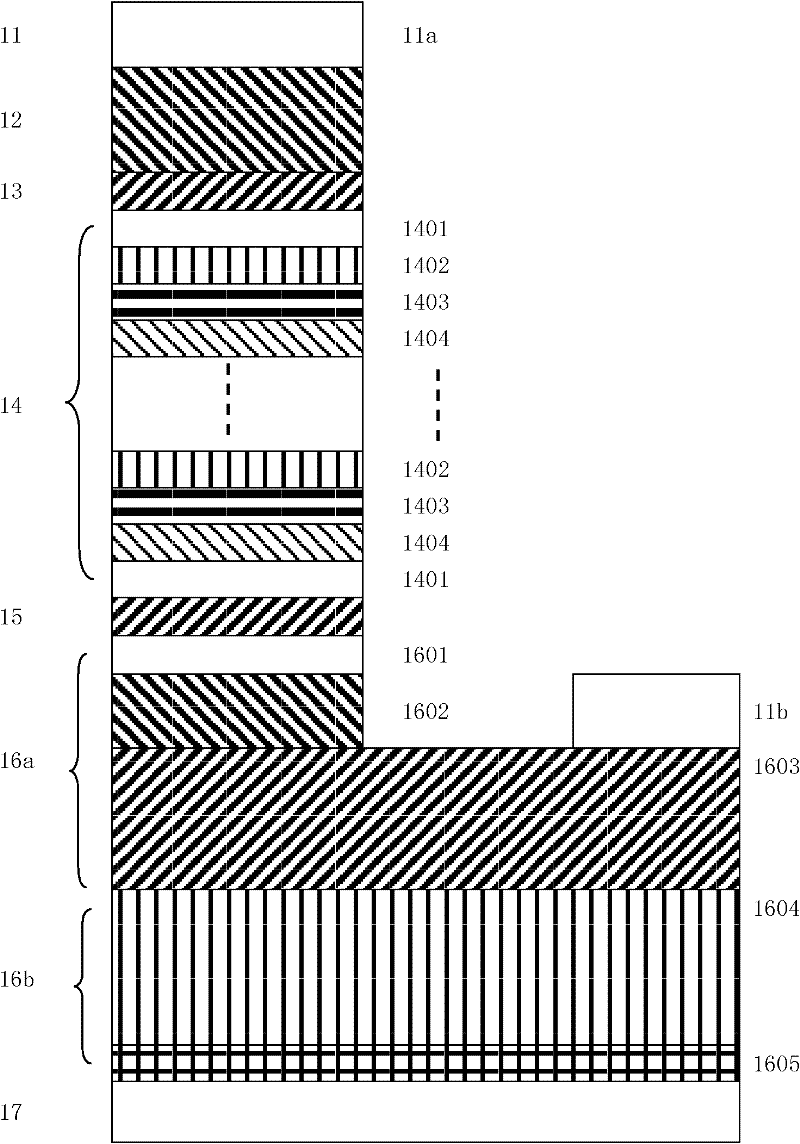

[0070] Red, green and blue three-color integrated tunable gallium nitride (GaN)-based light-emitting element, the schematic diagram of the single-wavelength light-emitting part thereof is shown in figure 1 , bottom-up including:

[0071] (1) Substrate 17

[0072] A transparent growth substrate 17, the material of which can be sapphire;

[0073] (2) Buffer layer 16b

[0074] The side close to the substrate 17 is a layer of about 1000nm GaN buffer layer 16b, which can be n-doped or undoped according to the chip structure. The buffer layer in this embodiment at least includes a 15-25nm GaN nucleation layer 1605 and a 1μm GaN layer 1604 for reducing lattice mismatch;

[0075] (3) n-type semiconductor contact layer 16a

[0076] Above the buffer layer 16b is an n-type semiconductor contact layer 16a of about 2000nm GaN material, which includes: a 500nm n-type GaN positioning layer 1602, this embodiment uses 500nm GaN:Si, n≥5×10 18 cm -3 , used to etch into a quantum dot positi...

Embodiment 2

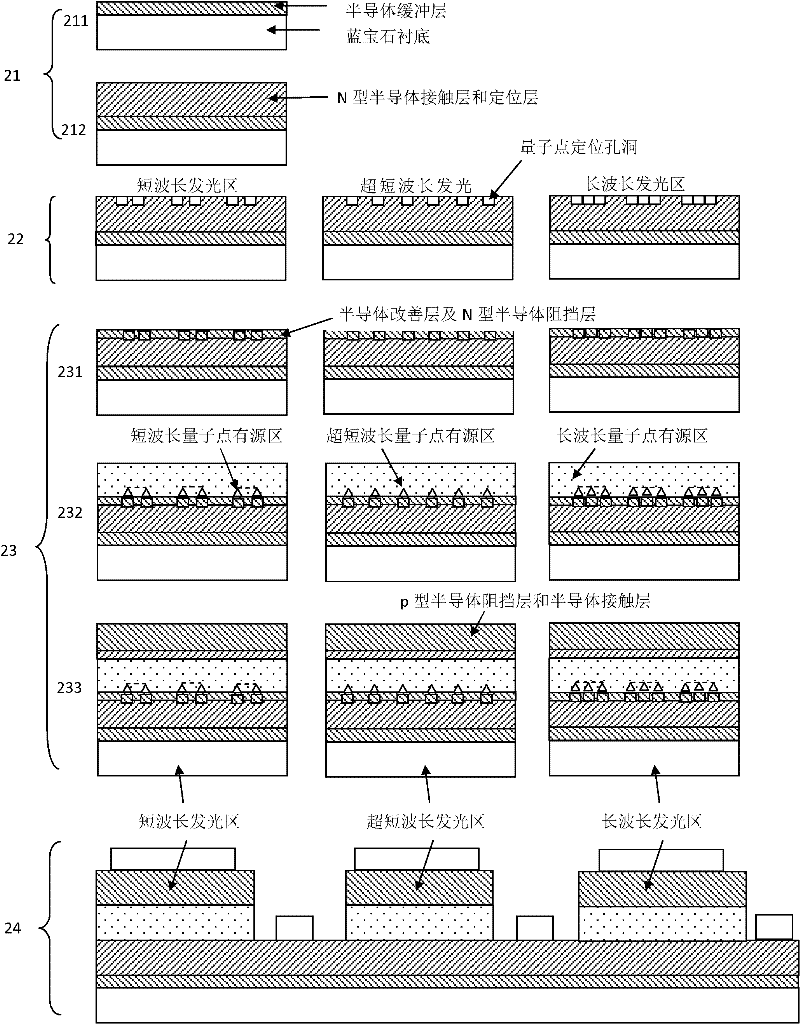

[0119] Red, green and blue three-color integrated tunable gallium nitride (GaN)-based light-emitting element, the schematic diagram of the single-wavelength light-emitting part thereof is shown in Figure 5 , bottom-up including:

[0120] (1) substrate 57;

[0121] (2) buffer layer 56b;

[0122] (3) n-type semiconductor contact layer 56a;

[0123] (4) n-type semiconductor barrier layer 55;

[0124] (5) Active layer 54;

[0125] (6) p-type semiconductor barrier layer 53;

[0126] (7) p-type semiconductor contact layer 52;

[0127] (8) Electrode layer 51 .

[0128] The difference between the single emission wavelength structure of this embodiment and Embodiment 1 lies in the active layer. Its active layer 54 uses mixed quantum dots and quantum wells as the main light-emitting structure, and from bottom to top at least includes:

[0129] 5-20nm GaN underlying semiconductor pad layer 5401; its energy gap is larger than that of the quantum dot layer 5407, but smaller than or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com