Soft measurement method for melt index of polymer

A melt index and soft measurement technology, applied in the field of polymers, can solve the problems of high estimation cost, rare melt index, and no consideration of physical and chemical properties and structural information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

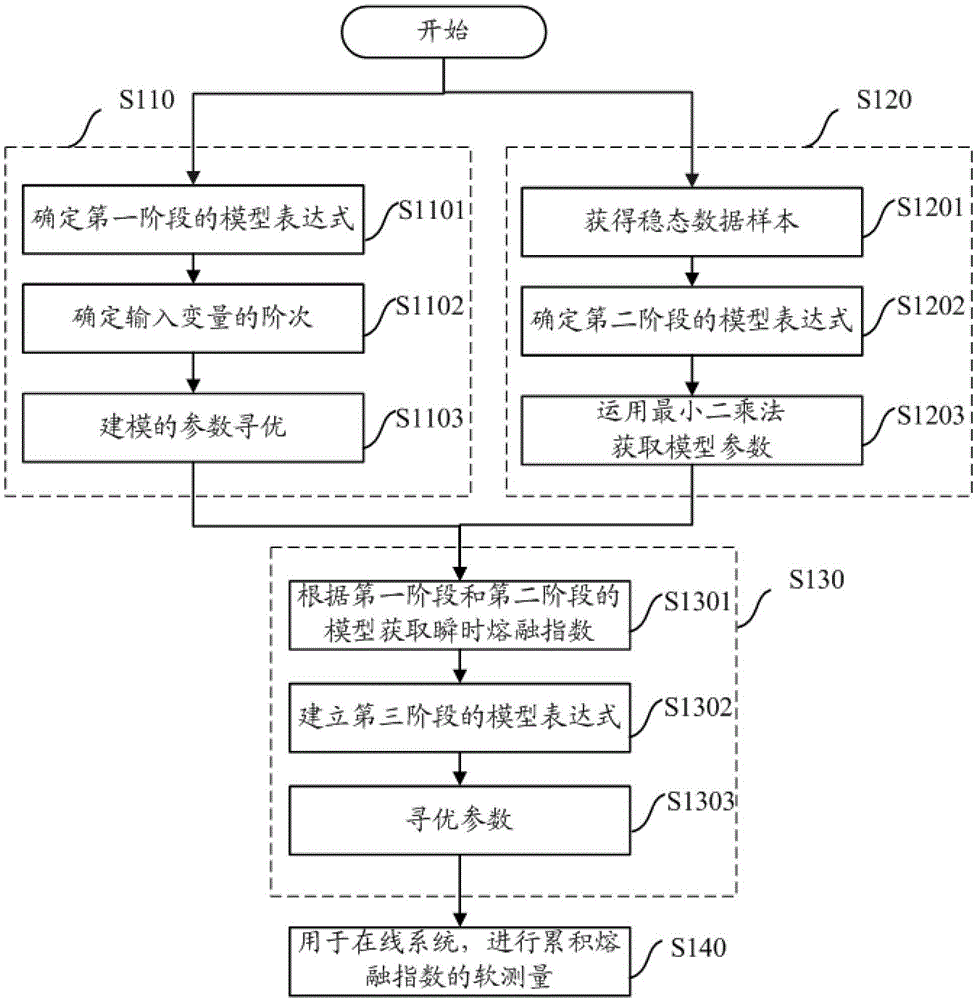

Method used

Image

Examples

example

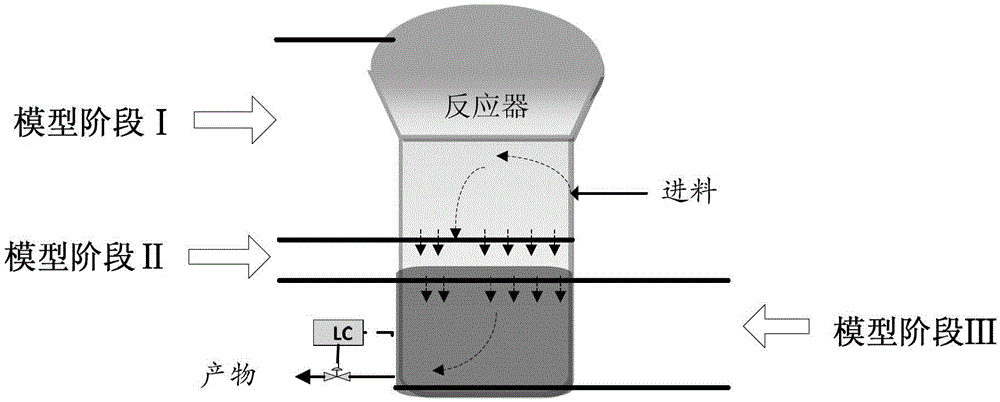

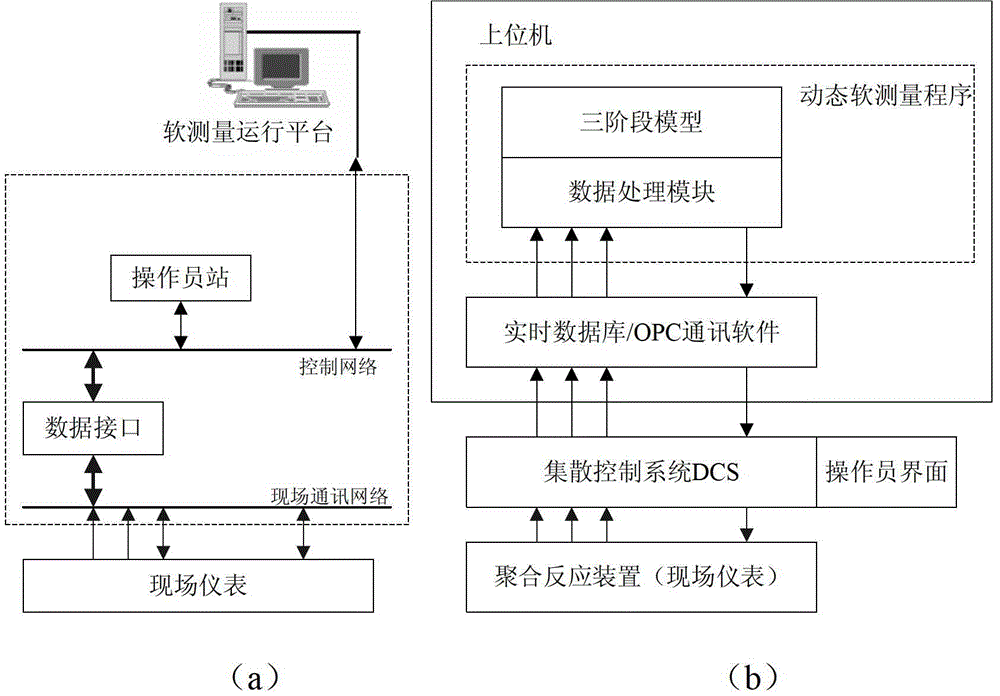

[0132] The method of the present invention will be further described below in conjunction with a simulation example.

[0133] Taking the polyethylene production process as an example, it is considered to obtain dynamic data from engineering simulation software, such as Aspen Polymer Plus and Aspen Dynamic Plus, and to establish an online soft-sensing model of polyethylene melt index based on this.

[0134] Consider the ratio of hydrogen to ethylene to σ H2 / C2 , butene ethylene ratio σ C4 / C2 and temperature T three controller setpoints as the system's operating variables. In order to generate dynamic data, 60 groups of input combinations are randomly sampled in the set Π, and the system is sequentially stimulated to generate dynamic data, where Π is shown in the following expression,

[0135] Π={(σ H2 / C2 ,σ C4 / C2 ,T)|σ H2 / C2 ∈[0.006,0.015],σ C4 / C2 ∈[0.04,0.13],T∈[90,110]}

[0136] The area corresponding to the melt index of the set Π is from 0.37 to 7.39, which has a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com