Method for using solar energy decomposing water to prepare hydrogen nanometer electrode

A nano-electrode and water-splitting technology, applied in chemical instruments and methods, catalyst activation/preparation, hydrogen production, etc., can solve problems such as poor light energy conversion efficiency, achieve reduced probability, high light conversion efficiency and light decomposition efficiency, and increase Effects of Photocatalytic Efficiency and Photowater Splitting Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

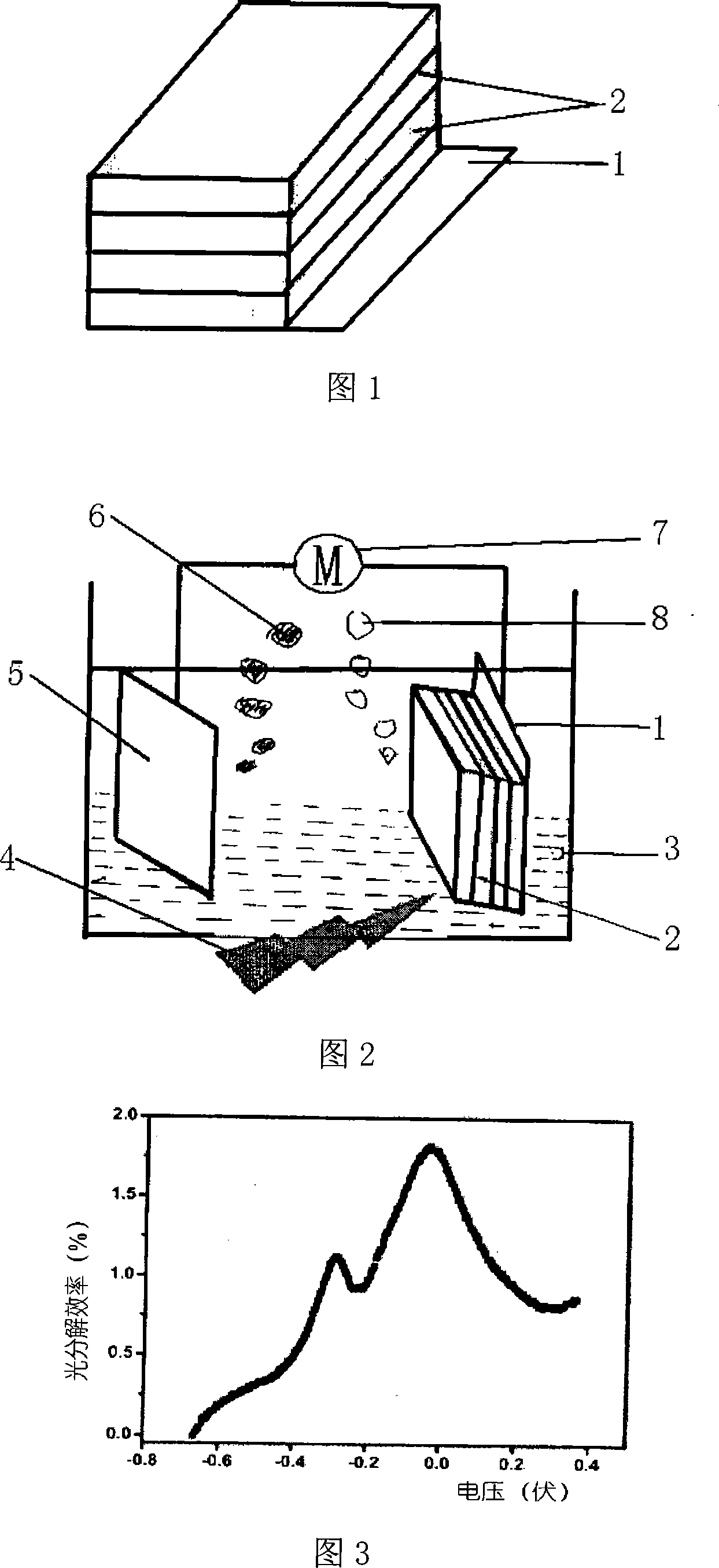

[0025] Embodiment 1: 500mg self-made TiO 2 The microspheres are dispersed into a mixed solution of ethanol: water = 2:1, an equal volume of 40 wt% polyethylene oxide aqueous solution is added, and the microspheres are uniformly dispersed by ultrasonic to prepare a pasty slurry. F-SnO 2 The glass is cut into 1cm×1.5cm base electrodes, cleaned with a special cleaning solution for conductive glass, ultrasonically cleaned with ethanol and acetone for 3 minutes, and dried with nitrogen. Treat with plasma for 2 minutes. The above slurry was spin-coated on F-SnO by spin-coating method 2 The surface was spin-coated at a rate of 1500 rpm. Then put the electrode into a muffle furnace and sinter at 450°C for 60 minutes. The prepared F-SnO 2 / TiO 2 The electrode is prepared as a photoelectrochemical cell as shown in Figure 2. In the photoelectrochemical cell, the base electrode 1 is used as the anode, the material of the cathode 5 is Pt wire, and 1 M potassium hydroxide (KOH) is the...

Embodiment 2

[0026] Example 2: 500mgTiO 2Nanoparticles (Degussa P25, composed of about 30% rutile and 70% anatase, particle size about 20 nm) were dispersed in ethanol: water (2:1) mixed solution, adding an equal volume of 40wt% polyoxygen Ethylene aqueous solution, ultrasonic dispersion, prepared into a paste slurry. F-SnO 2 The glass is cut into 1cm×1.5cm base electrodes, cleaned with a special cleaning solution for conductive glass, ultrasonically cleaned with ethanol and acetone for 3 minutes, and dried with nitrogen. Treat with plasma for 2 minutes. The above slurry was spin-coated on F-SnO by spin coating. 2 The surface was spin-coated at a rate of 1500 rpm. Then put the electrode into a muffle furnace for sintering at 450°C for 60 minutes. The prepared F-SnO 2 / TiO 2 (P25) The electrode is prepared into a photoelectrochemical cell as shown in Figure 2. In the photoelectrochemical cell, the base electrode 1 is used as the anode, the material of the cathode 5 is Pt wire, and th...

Embodiment 3

[0027] Example 3: 500 mg self-made TiO 2 The microspheres are dispersed into ethanol: water (2:1) mixed solution, and an equal volume of 40 wt% polyoxyethylene aqueous solution is added, and the microspheres are dispersed uniformly by ultrasonic to prepare a pasty slurry. F-SnO 2 The glass is cut into 1cm×1.5cm substrate electrodes, cleaned with a special cleaning solution for conductive glass, ultrasonically cleaned with ethanol and acetone for 3 minutes, blown dry with nitrogen, and treated with plasma for 2 minutes. The above slurry was coated on F-SnO by spin coating 2 The surface was spin-coated at a rate of 1500 rpm. Then put the electrode into a muffle furnace for sintering at 450°C for 60 minutes. Take out the electrode, drop 0.5 mole of hexamethylenetetramine and 0.5 mole of zinc nitrate on the surface of the electrode, each 2ml, spin coating after 5 minutes to shake off the excess solution, heat treatment in a 200 degree oven for 5 minutes, repeat the above operat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com