Optical-transfer packaging adhesive film, and preparation technique and application thereof

A technology for encapsulating adhesive films and converting light, which is applied in adhesives, photovoltaic power generation, film/sheet adhesives, etc., can solve problems that do not involve the processing technology and preparation of wavelength conversion particles, power improvement, Problems such as dispersion and compatibility, to reduce the harm of ultraviolet rays penetrating to the backplane, improve power, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

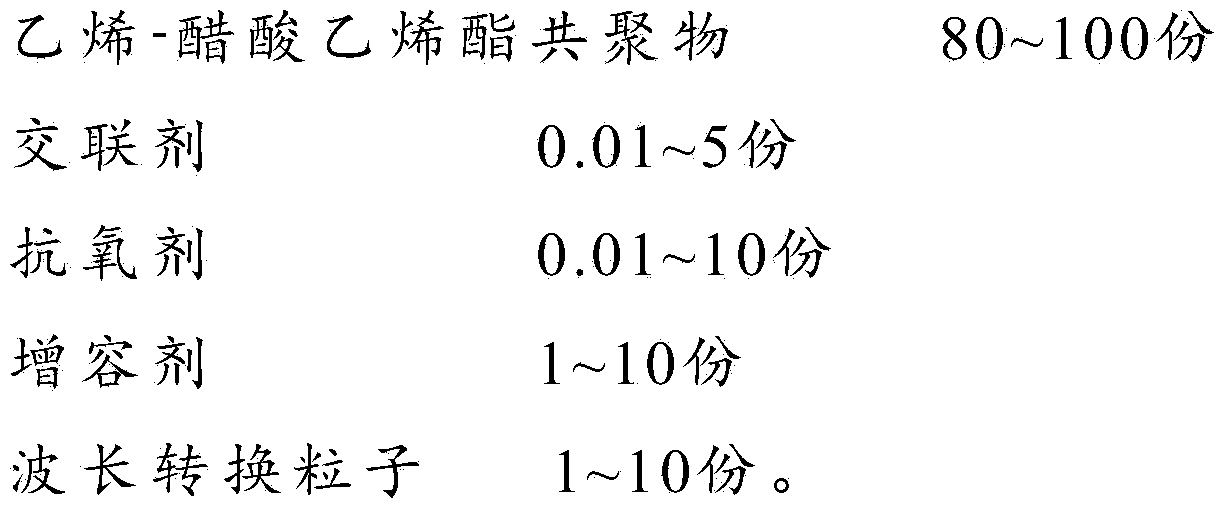

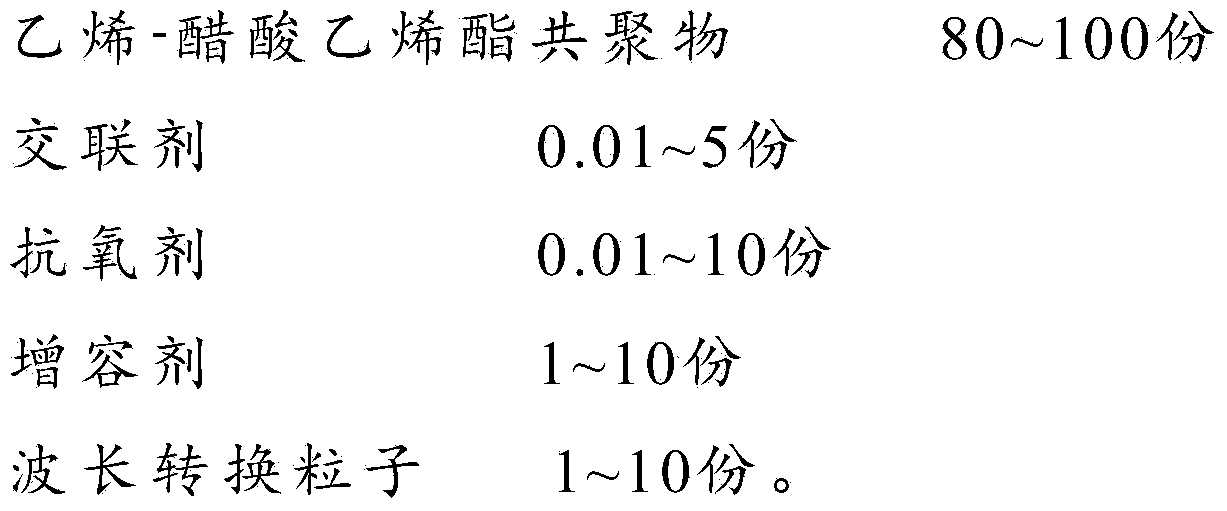

[0038] raw material

[0039] The above-mentioned materials were granulated in a twin-screw extruder according to the dosage of the formula, and extruded through a T-die of a coat hanger to form a film at a temperature of 90° C. and a film thickness of 0.3 mm.

Embodiment 2

[0041] raw material

[0042] Triphenyl phosphite

[0043] The above-mentioned materials were granulated in a twin-screw extruder according to the dosage of the formula, and extruded through a T-die of a coat hanger to form a film at a temperature of 100° C. and a film thickness of 0.4 mm.

Embodiment 3

[0045] raw material

[0046] The above-mentioned materials were granulated in a twin-screw extruder according to the dosage of the formula, and extruded through a T-die of a coat hanger to form a film at a temperature of 100° C. and a film thickness of 0.4 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com