Organic thin film transistor and manufacturing method thereof

An organic thin film and manufacturing method technology, which is applied in semiconductor/solid state device manufacturing, electric solid state device, semiconductor device and other directions, can solve the problems of increased manufacturing cost, complex process and many processing steps of organic thin film transistors, and achieves simplified manufacturing process, Reduce manufacturing costs, overcome the effects of complex patterning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

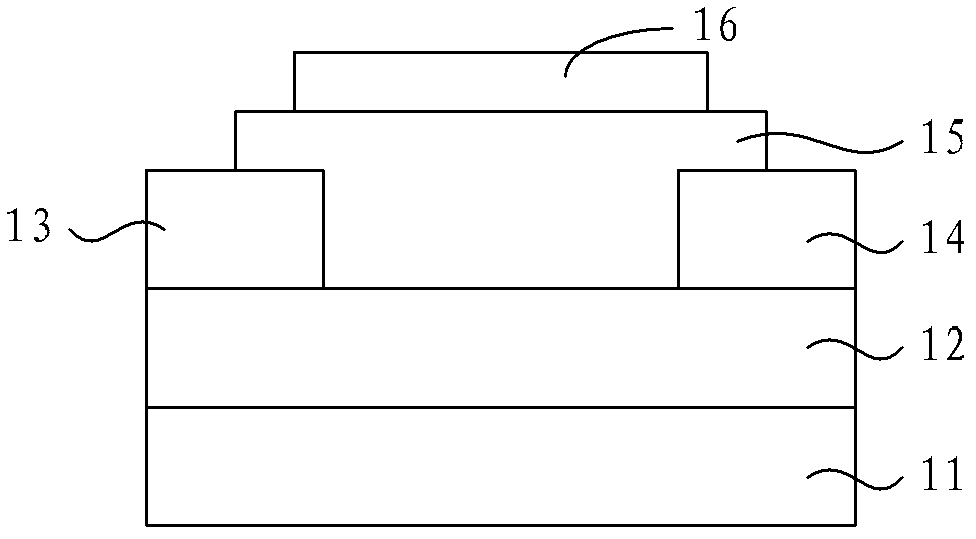

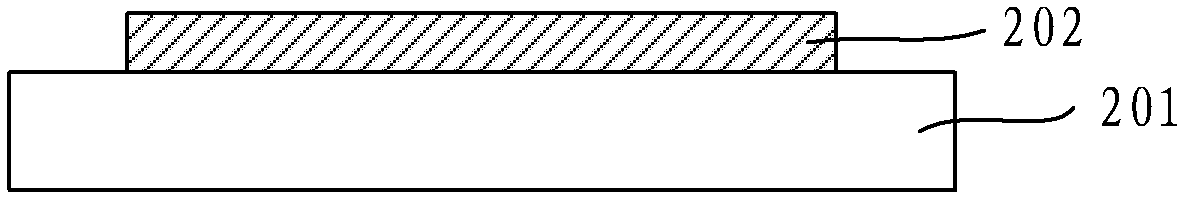

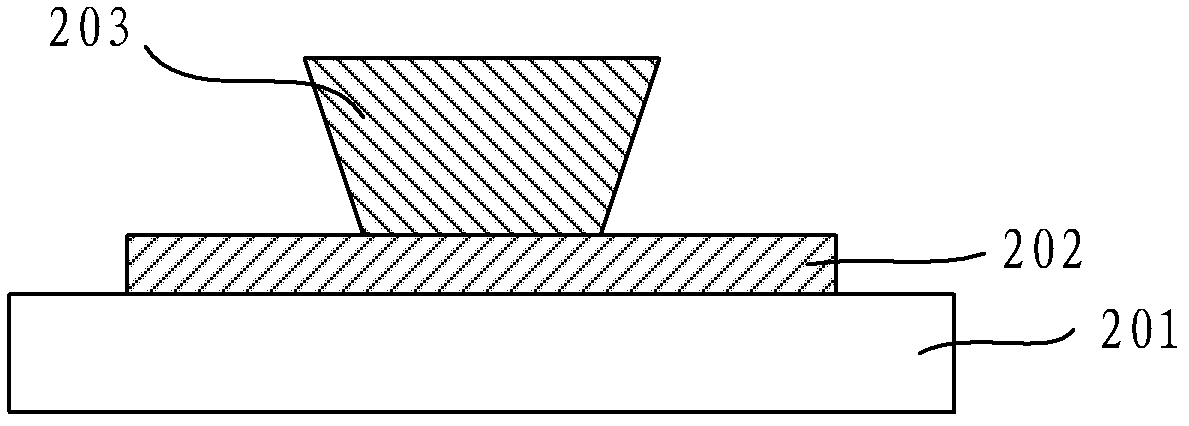

[0023] This embodiment provides an organic thin film transistor, such as Figure 2C As shown, the organic thin film transistor includes: a substrate 201 , an organic semiconductor layer 202 , a gate insulating layer 203 , a gate electrode 204 , a source electrode 205 and a drain electrode 206 . A gate insulating layer 203 is formed on the organic semiconductor layer 202; a gate electrode 204 covers the top surface of the gate insulating layer 203; a source electrode 205 and a drain electrode 206 are formed on the organic semiconductor layer 202, facing each other across the gate insulating layer 203, and respectively Close to the sidewall 207 of the gate insulating layer 203; the angle α between the sidewall 207 and the bottom surface of the source electrode 205 or the drain electrode 206 close to the sidewall is not greater than 90 degrees. Wherein, the material of the gate insulating layer 203 is a photosensitive material.

[0024] The manufacturing method of the above-ment...

Embodiment 2

[0038] This embodiment provides an organic thin film transistor, such as image 3 As shown, the organic thin film transistor includes: a substrate 301 , an organic semiconductor layer 302 , a gate insulating layer 303 , a gate electrode 304 , a source electrode 305 and a drain electrode 306 . A gate insulating layer 303 is formed on the organic semiconductor layer 302; a gate electrode 304 covers the top surface of the gate insulating layer 303; a source electrode 305 and a drain electrode 306 are formed on the organic semiconductor layer 302, facing each other across the gate insulating layer 303, and respectively Close to the sidewall 307 of the gate insulating layer 303; the angle between the sidewall 307 and the bottom surface of the source electrode 305 or the drain electrode 306 close to the sidewall is 90 degrees (that is, the sidewall 307 is perpendicular to the organic semiconductor layer 302 top surface). Wherein, the material of the gate insulating layer 303 is a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com