Filtrate reducer for oil field drilling fluid and preparation method thereof

A filtrate reducer and oilfield drilling technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as unstable product quality, difficulty in controlling the degree of sulfonation, and affecting the effect of fluid loss control, and achieve improved Thermal stability and salt resistance, ease of control, effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

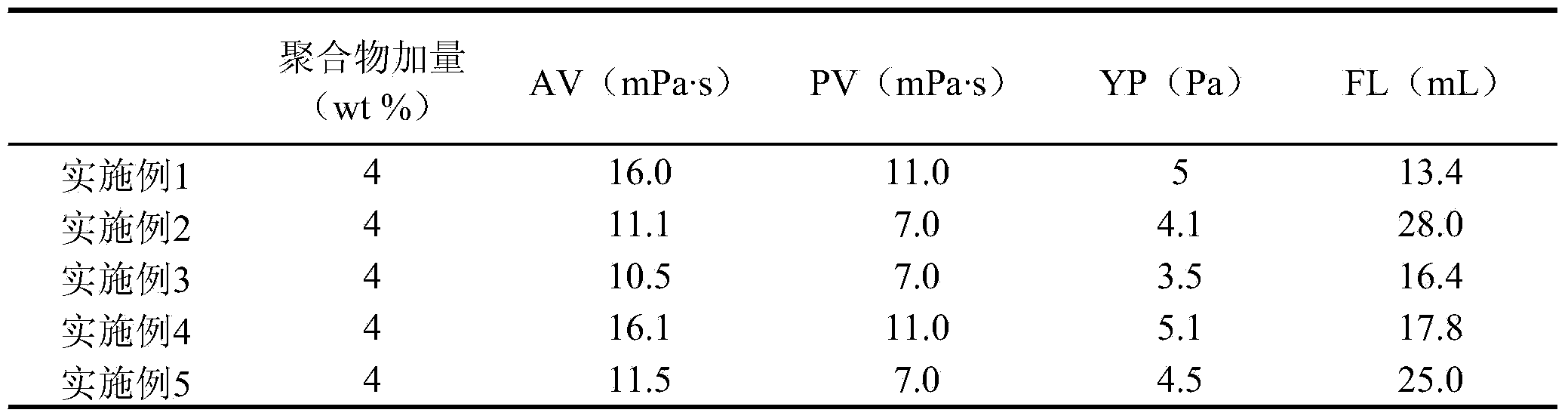

Embodiment 1

[0013] Accurately weigh 1.736g p-aminobenzenesulfonic acid, 15.624g p-toluenesulfonic acid and 17.1g phenol into a three-necked flask; Adjust the value to 9; set the reaction temperature to 85°C, heat up and stir to dissolve; weigh 19.32g of formaldehyde in a constant pressure dropping funnel, control the dropping time, and completely add it to the reaction system within 1 hour; Start timing, react for 6 hours and cool to obtain a brownish-red liquid product, wash with absolute ethanol until a white flocculent precipitate appears, and after separation, dry the precipitate in a vacuum oven for 24 hours to obtain the fluid loss reducer for drilling fluid.

Embodiment 2

[0015] Accurately weigh 3.472g p-aminobenzenesulfonic acid, 13.88g p-toluenesulfonic acid and 16.4g phenol into a three-necked flask; Adjust the value to 9; set the reaction temperature to 70°C, heat up and stir to dissolve; weigh 20.02g of formaldehyde in a constant pressure dropping funnel, control the dropping time, and completely add it to the reaction system within 1.2 hours; Start timing, react for 4 hours and cool to obtain a brownish-red liquid product, wash with absolute ethanol until a white flocculent precipitate appears, and after separation, dry the precipitate in a vacuum drying oven for 24 hours to obtain the fluid loss reducer for drilling fluid.

Embodiment 3

[0017] Accurately weigh 5.2078g p-aminobenzenesulfonic acid, 12.152g p-toluenesulfonic acid and 15.9g phenol into the three-necked flask; add 20ml of sodium hydroxide solution with a mass percentage concentration of 50% to adjust the pH of the reaction system Adjust the value to 9; set the reaction temperature to 85°C, heat up and stir to dissolve; weigh 20.52g of formaldehyde in the constant pressure dropping funnel, control the dropping time, and completely add it to the reaction system within 1.3 hours; Start timing, react for 6 hours and cool to obtain a brownish-red liquid product, wash with absolute ethanol until a white flocculent precipitate appears, and after separation, dry the precipitate in a vacuum oven for 24 hours to obtain the fluid loss reducer for drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com