Preparation method of bionic porous ceramic with complex three-dimensional structure

A three-dimensional structure, complex technology, applied in the field of preparation of complex three-dimensional structure ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

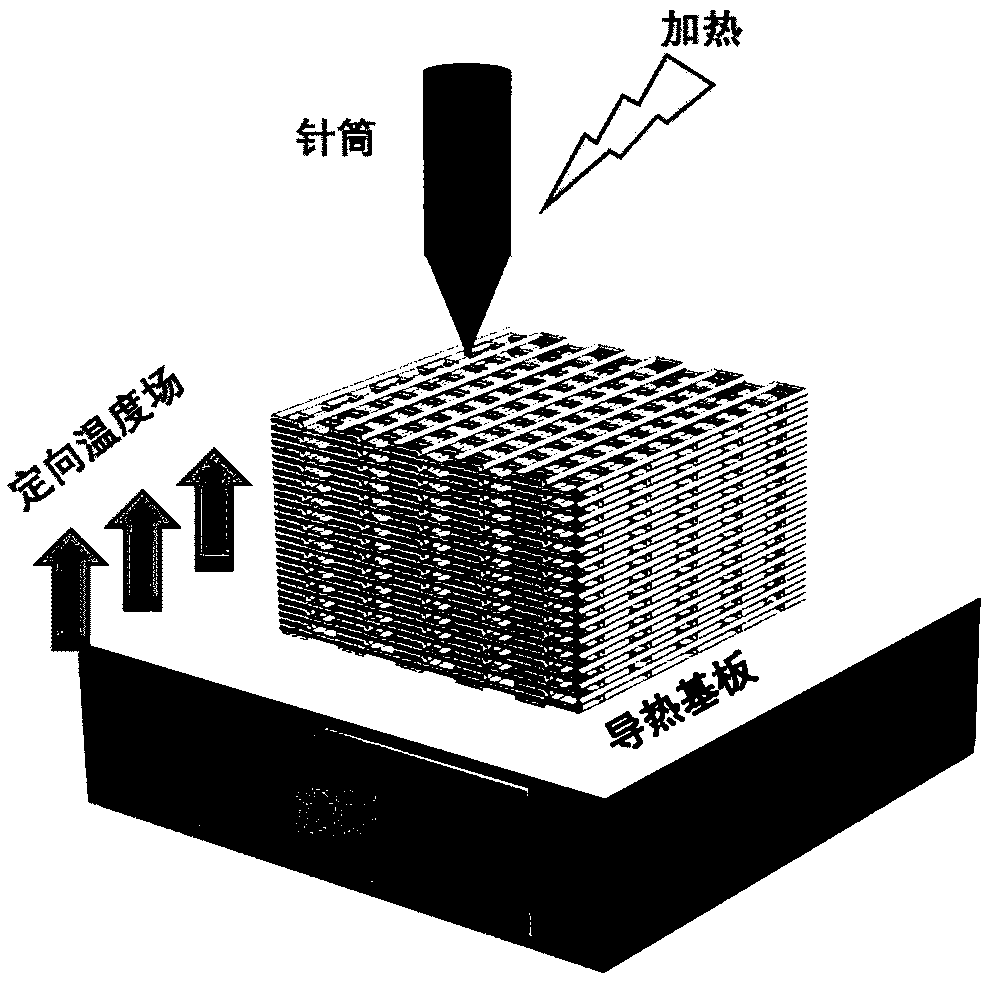

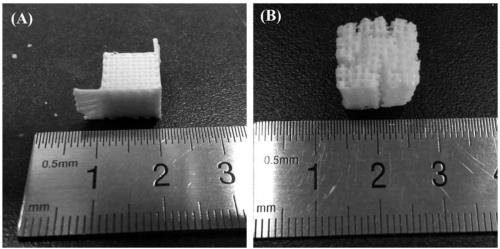

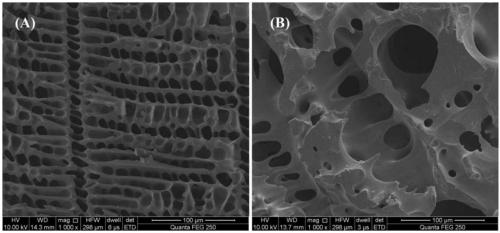

[0060] Polycarbosilane is used as the ceramic precursor, and camphene is used as the organic solvent to prepare multi-scale porous and complex three-dimensional silicon carbide ceramics by the method of the present invention.

[0061] Heat the camphene to above 35°C to fully melt it. Subsequently, 10wt.%-20wt.% of polycarbosilane powder is added, and the powder is fully dissolved in the camphene under the action of magnetic stirring. Then, 20wt.% (mass ratio of crosslinking agent to ceramic precursor, the same below) of divinylbenzene was added dropwise as a crosslinking agent. Under the environment of 120°C, magnetic stirring for 3h promoted partial crosslinking of polycarbosilane.

[0062] The slurry is then placed in a syringe, the temperature of the syringe is increased to 35°C or more, and it is allowed to stand for 1-2 hours for defoaming. Then adjust the temperature of the syringe to 25-35°C to adjust the rheological properties of the slurry to an appropriate range. At th...

example 2

[0067] Polycarbosilane is used as a ceramic precursor, and cyclooctane is used as an organic solvent to prepare multi-scale porous and complex three-dimensional silicon carbide ceramics by the method of the present invention.

[0068] Heat the cyclooctane to above 14°C to fully melt it. Subsequently, 10wt.%-20wt.% of polycarbosilane powder is added, and the powder is fully dissolved in cyclooctane under the action of magnetic stirring. Then, 20wt.% (mass ratio of crosslinking agent to ceramic precursor, the same below) of divinylbenzene was added dropwise as a crosslinking agent. Under the environment of 120°C, magnetic stirring for 3h promoted partial crosslinking of polycarbosilane.

[0069] The slurry is then placed in a syringe, the temperature of the syringe is raised to above 14°C, and it is allowed to stand for 1-2 hours for defoaming treatment. Then adjust the temperature of the syringe to 4-14°C, and adjust the rheological properties of the slurry to an appropriate range...

example 3

[0074] Polyoxysilane is used as a ceramic precursor, and tert-butanol is used as an organic solvent to prepare a multi-scale porous complex three-dimensional structure carbon-silicon-oxygen ternary ceramic by adopting the method of the present invention.

[0075] Heat tert-butanol to above 28°C to fully melt it. Subsequently, 10-20 wt.% of polyoxysilane powder is added, and the powder is fully dissolved in tert-butanol under the action of magnetic stirring. Then, 10-20wt.% (mass ratio of crosslinking agent to ceramic precursor, the same below) of dibutyltin dilaurate is added dropwise as a crosslinking agent. Under the environment of 50-60℃, magnetic stirring for 3h promotes partial crosslinking of polyoxysilane.

[0076] The slurry is then placed in a syringe, the temperature of the syringe is raised to above 28°C, and it is allowed to stand for 1-2 hours for defoaming treatment. Then adjust the temperature of the syringe to 18-28°C to adjust the rheological properties of the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com