A 4D printing method for curved surface ipmc

A curved surface, 4D technology, applied in the field of additive manufacturing, to achieve good heat transfer effect and improve rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1) Carry out surface intelligent structure design according to functional requirements:

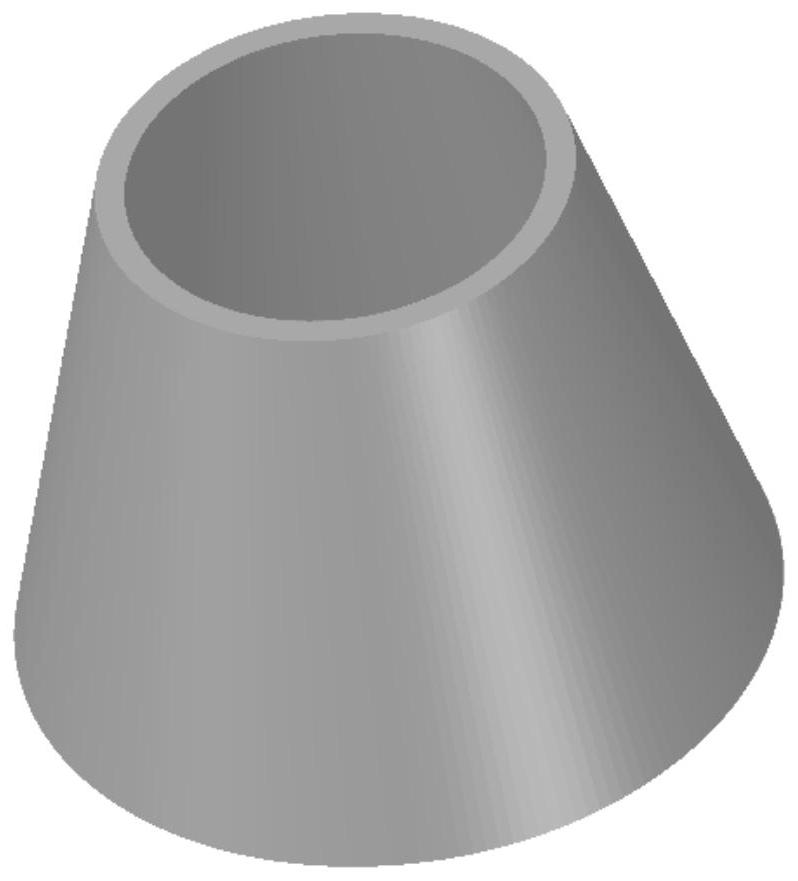

[0063] The functional requirement is a deformable ring, and the designed curved surface intelligent structure is a circular frustum shell, with a top radius of 5cm, a bottom radius of 10cm, a height of 20cm, and a thickness of 0.015mm for the curved surface intelligent structure. The simulation is carried out through the thermal equivalent model to meet the design requirements .

[0064] 2) Conformal matrix design:

[0065] The curved surface conformal matrix is also a circular frustum shell, with a top radius of 5cm, a bottom radius of 15cm, a height of 30cm, and a thickness of 0.01mm for the conformal matrix structure. Silicon rubber is used for heating, and the temperature adjustment range is 60°.

[0066] 3) Printing ink configuration:

[0067] Take 50g of Nafion solution with a mass fraction of 20% and mix it with 50g of dimethylacetamide for heating and magnetic stirring ...

Embodiment 2

[0075] 1) Carry out surface intelligent structure design according to functional requirements:

[0076] The functional requirement is to realize the displacement and deformation of the departmental structure. The curved surface intelligent structure is designed as a circular frustum shell with a top radius of 1cm, a bottom radius of 2cm, and a height of 1cm. It extends 4cm along the generatrix of the circular frustum shell, and the thickness of the curved surface intelligent structure is 0.500. mm, simulated through the thermal equivalent model to meet the design requirements.

[0077] 2) Conformal matrix design:

[0078] The curved surface conformal matrix is also a circular frustum shell, with a top radius of 1m, a bottom radius of 4cm, a height of 6cm, and a thickness of 0.15mm for the conformal matrix structure. Graphene is used for contact heating, and the temperature adjustment range is 70°.

[0079] 3) Printing ink configuration:

[0080] Take 60g of Nafion solution...

Embodiment 3

[0088] 1) Surface intelligent structure design:

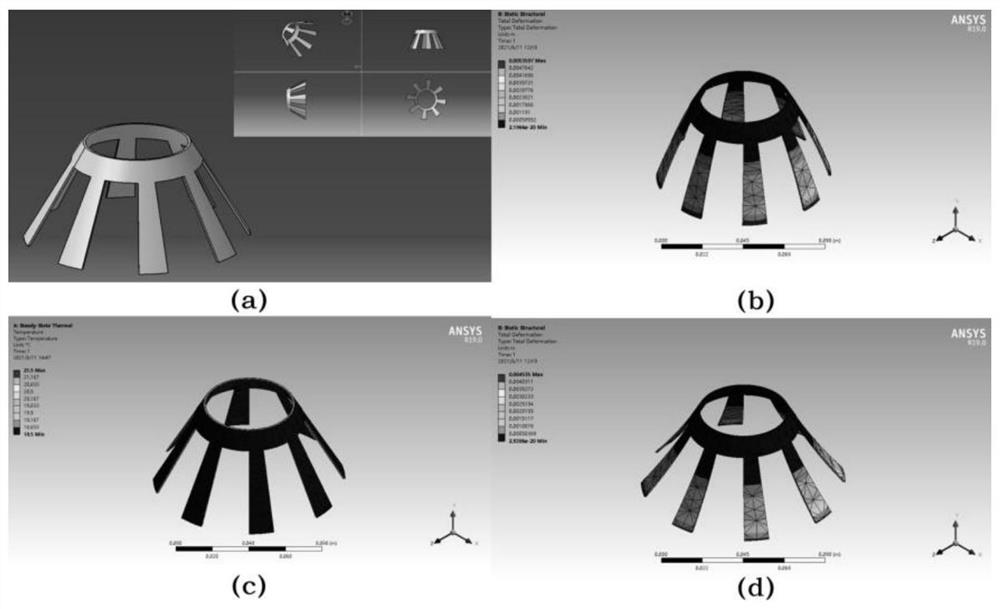

[0089] The functional requirement is to realize the overall stretching and deformation of the structure. The curved surface intelligent structure is designed as a round table shell with a top radius of 3cm, a bottom radius of 3.25cm, and a height of 10cm. Eight stretching surfaces are evenly developed along the side of the round table, and the busbar extends 4cm in length. The stretching surface with an angle of 15°, the thickness of the stretching surface along the curved surface smart structure is 2.500mm, and the simulation is carried out through the thermal equivalent model to meet the design requirements.

[0090] 2) Conformal matrix design:

[0091] The curved surface conformal matrix is also a circular frustum shell, with a top radius of 2.5cm, a bottom radius of 4cm, a height of 6cm, and a thickness of 0.20mm for the conformal matrix structure. Polyimide is used for contact heating, and the temperature adjustment rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com