Application of cellulose nanofiber as flow pattern regulator for drilling fluids

A technology of flow regulator and nanofiber, which is applied in the field of drilling fluid, can solve the problems of high cost and poor environmental protection performance, and achieve the regulation of rheological properties, enhanced shear thinning and thixotropy, and good "viscosity increase and shear reduction" "The effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare a 1%wt water dispersion of carboxymethyl cellulose, under the action of a homogeneous pressure of 140MPa, use a dynamic ultra-high pressure micro-fluidizer to repeatedly process the carboxymethyl cellulose water dispersion 8 times, and the obtained product is heated at 12000r Centrifuge at 20 min at 80°C for 20 min, and dry at 80°C for 6 h to obtain carboxymethyl cellulose nanofibers with an average diameter of 21 nm and an aspect ratio of 335.

Embodiment 2

[0025] Cationic cellulose was prepared into a 3%wt aqueous dispersion, and under the action of a homogeneous pressure of 120MPa, the carboxymethyl cellulose aqueous dispersion was repeatedly treated 10 times with a dynamic ultra-high pressure micro-fluidizer, and the obtained product was heated at 11000r / min Centrifuge for 30 minutes and dry at 100°C for 4 hours to obtain cationic cellulose nanofibers with an average diameter of 13 nm and an aspect ratio of 458.

Embodiment 3

[0027] Prepare 2%wt aqueous dispersion of hydroxyethyl cellulose, under the action of homogeneous pressure of 160MPa, use dynamic ultra-high pressure micro-fluidizer to repeatedly process the hydroxyethyl cellulose aqueous dispersion 6 times, and the obtained product is heated at 12000r Centrifuge at 100°C for 20 minutes, and dry at 100°C for 5 hours to obtain hydroxyethyl cellulose nanofibers with an average diameter of 28nm and an aspect ratio of 275.

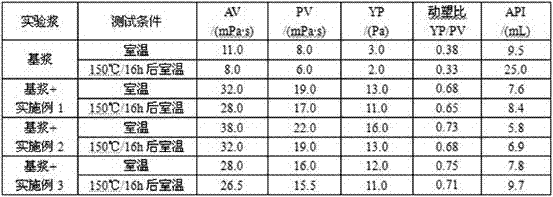

[0028] The effects of Examples 1-3 will be described below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com