A breathable brick prepared from industrial by-product aluminum chrome slag and its production method

A technology of aluminum chromium slag and by-products, applied in the field of breathable bricks, to achieve good anti-stripping performance and widen the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

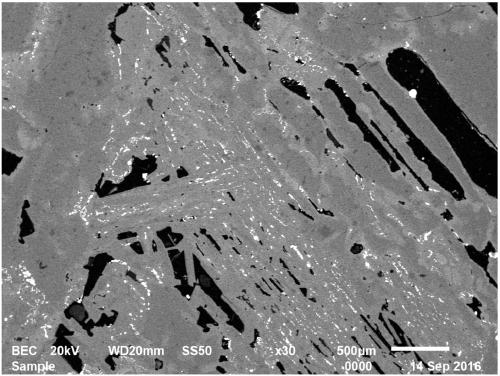

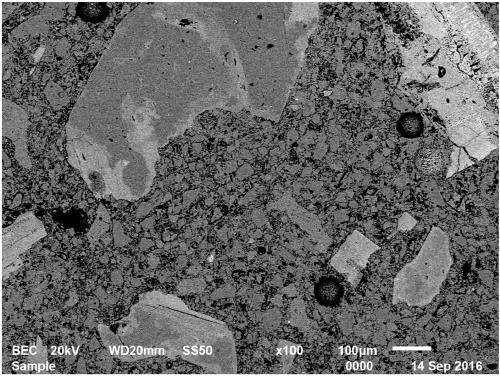

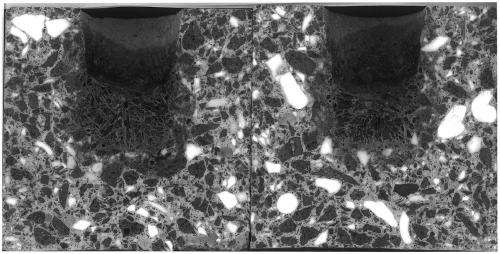

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below by way of example:

[0022] 1. The raw material ratio of the breathable core is as follows:

[0023]

[0024] 1.1, prepare materials according to any formula in the above table;

[0025] 1.2, Grind the fine powder for 1 hour to make it fully mixed;

[0026] 1.3, fully mix the well-mixed fine powder and aggregate;

[0027] 1.4. Add the above premixed material to the corresponding weight of water, and stir evenly in a forced mixer;

[0028] 1.5, the evenly stirred mud is formed by vibration;

[0029] 1.6, maintain in an environment with a temperature of 60°C and a relative humidity of 75%;

[0030] 1.7. After curing, remove the mold and dry at 150°C for 48 hours according to a certain drying system;

[0031] 1.8, the dried green body is fired at a high temperature of 1600°C according to a certain firing system;

[0032] 1.9. After the fired body is clad with a metal shell, the production is completed.

[0033] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com