Controllable low-strength material based on shield slurry and regenerated sand powder as well as preparation method and application of controllable low-strength material

A reclaimed sand, low-strength technology, applied in cement production, climate sustainability, infrastructure engineering, etc., can solve the problems of increasing the difficulty of shield mud reuse, increasing the difficulty of reuse, improper handling of shield mud, etc. , achieving significant social and economic benefits, low strength requirements, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

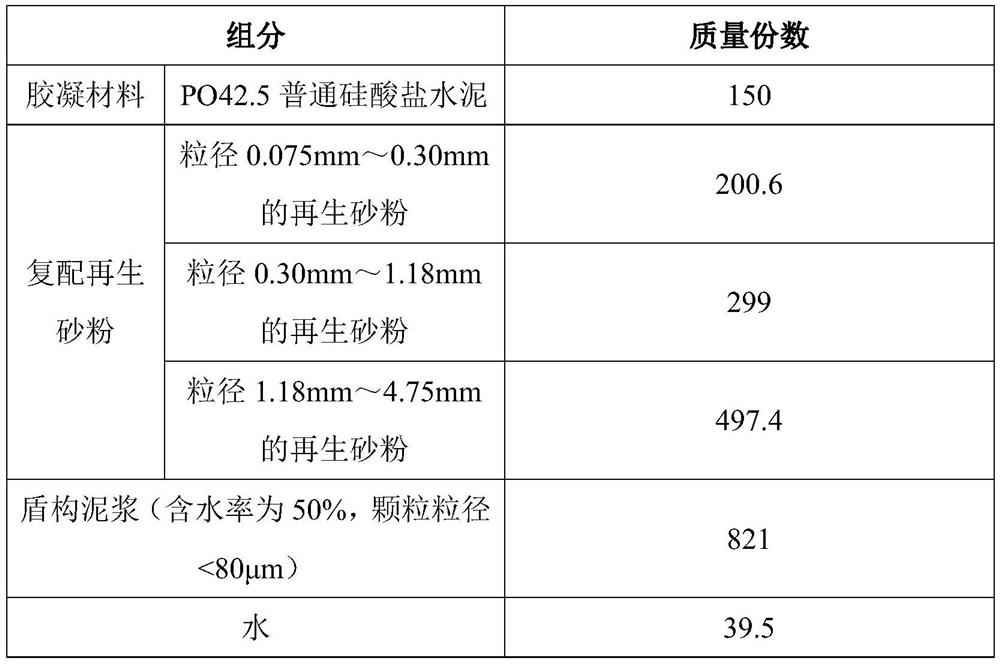

[0033] A controllable low-strength material based on shield mud and recycled sand powder, its composition is shown in the following table:

[0034] Table 1 Composition of a controllable low-strength material based on shield mud and recycled sand powder

[0035]

[0036] Note:

[0037] Compound recycled sand powder: It is made by crushing and screening waste red bricks, mortar and concrete;

[0038] Shield mud: The mud produced by earth pressure balance method shield engineering is made by flocculation and concentration.

[0039] The above-mentioned preparation method of the controllable low-strength material based on shield mud and recycled sand powder includes the following steps:

[0040] PO42.5 ordinary Portland cement, recycled sand powder with a particle size of 0.075mm to 0.30mm, recycled sand powder with a particle size of 0.30mm to 1.18mm, recycled sand powder with a particle size of 1.18mm to 4.75mm, shield mud and The water is mixed evenly, and the controllable...

Embodiment 2

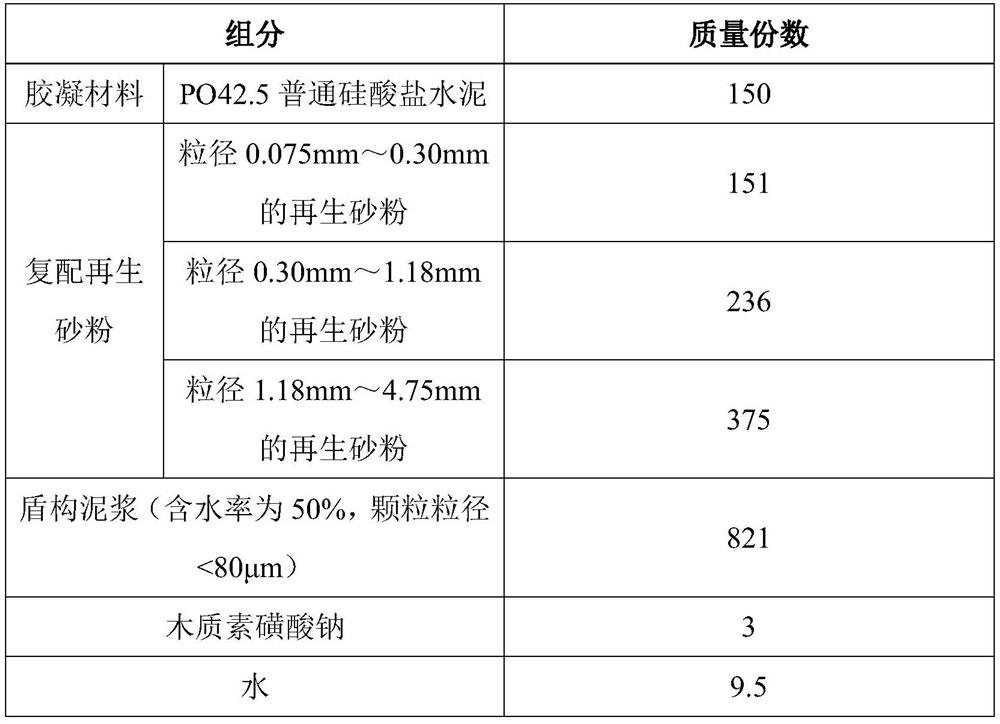

[0042] A controllable low-strength material based on shield mud and recycled sand powder, its composition is shown in the following table:

[0043] Table 2 Composition of a controllable low-strength material based on shield mud and recycled sand powder

[0044]

[0045] Note:

[0046] Compound recycled sand powder: It is made by crushing and screening waste red bricks, mortar and concrete;

[0047] Shield mud: The mud produced by earth pressure balance method shield engineering is made by flocculation and concentration.

[0048] The above-mentioned preparation method of the controllable low-strength material based on shield mud and recycled sand powder includes the following steps:

[0049] PO42.5 ordinary Portland cement, recycled sand powder with a particle size of 0.075mm to 0.30mm, recycled sand powder with a particle size of 0.30mm to 1.18mm, recycled sand powder with a particle size of 1.18mm to 4.75mm, shield mud, Sodium lignosulfonate and water are evenly mixed t...

Embodiment 3

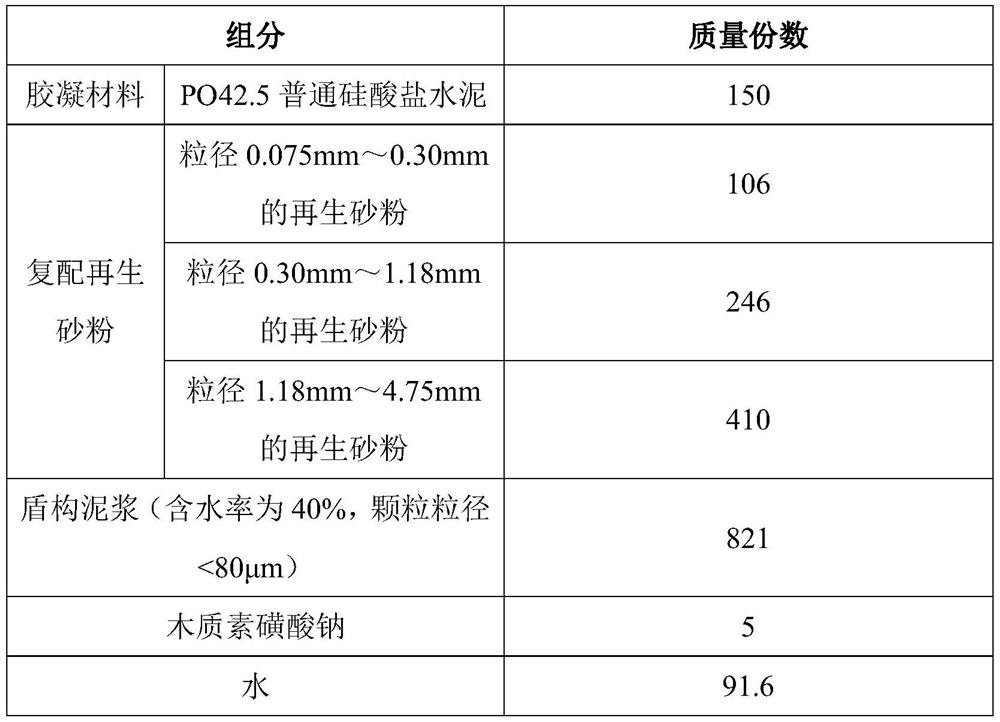

[0051] A controllable low-strength material based on shield mud and recycled sand powder, its composition is shown in the following table:

[0052] Table 3 Composition of a controllable low-strength material based on shield mud and recycled sand powder

[0053]

[0054] Note:

[0055] Compound recycled sand powder: It is made by crushing and screening waste red bricks, mortar and concrete;

[0056] Shield mud: The mud produced by earth pressure balance method shield engineering is made by flocculation and concentration.

[0057] The above-mentioned preparation method of the controllable low-strength material based on shield mud and recycled sand powder includes the following steps:

[0058]PO42.5 ordinary Portland cement, recycled sand powder with a particle size of 0.075mm to 0.30mm, recycled sand powder with a particle size of 0.30mm to 1.18mm, recycled sand powder with a particle size of 1.18mm to 4.75mm, shield mud, Sodium lignosulfonate and water are evenly mixed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com