Spiral-type jatropha curcas crude oil extraction machine

A screw-type jatropha technology, applied in the field of screw-type jatropha crude oil extractors, can solve the problems of troublesome loading and unloading cakes, large floor space, long pressing cycle, etc., and achieves simple operation, stable operation, and avoids long pressing cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

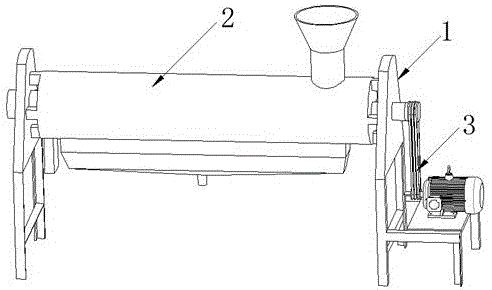

[0027] Such as Figure 1-4 As shown, the spiral jatropha crude oil extractor includes a frame 1, an oil squeezing device 2, and a power unit 3.

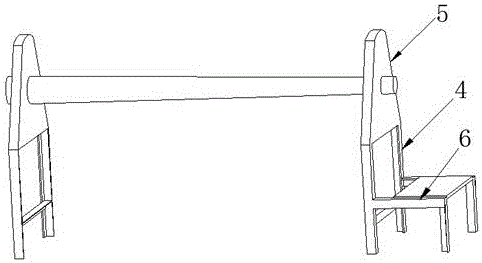

[0028] The frame 1 is composed of a support frame 4, a plate frame 5, and a motor frame 6. The support frame 4 is welded and fixed by three Q235B equilateral angle steels, which can effectively reduce the vibration of the whole machine and promote the stable operation of the whole machine. The plate frame 5 is welded on the upper end of the support frame 4 and the support frame 4 to form a bracket. There are two brackets. The oil pressing device 2 is installed on the two plate frames 5. The plate frame 5 is processed by a 1.5cm thick steel plate. , the shape is approximately trapezoidal, but the upper end is a circular arc structure with large rounded corners, which not only ensures the aesthetics of the frame 1, but also facilitates the stable installation of the squeezing oil pressing device 2.

[0029] The squeeze oil extraction ...

Embodiment 2

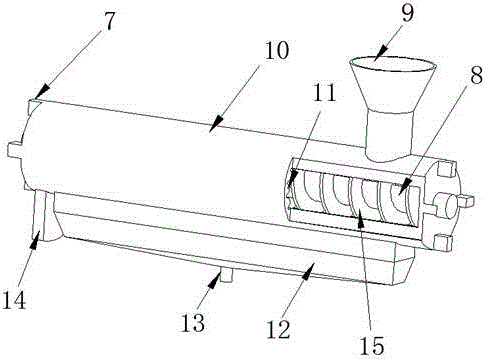

[0035] On the basis of Example 1, such as Figure 5 As shown, bolts 11 are evenly arranged on the inner wall of the squeeze barrel 10, and the distance between two adjacent bolts 11 is 0.4-0.8cm. The bolts 11 have a trapezoidal structure, but their long sides are circular arcs. shape, tangent to the inner wall of the squeeze barrel 10, after the bolt 11 is set on the inner wall of the squeeze barrel 10, the outer edge of the screw conveyor blade 15 is tangent to the surface of the bolt 11, and the bolt 11 on the inner wall of the bottom of the squeeze barrel 10 is removed from the The top of the oil collecting port 12 traverses until it reaches the right side of the opening of the slag discharge port 14 .

[0036] Under the extrusion conveying effect of the squeezing shaft 8 and the screw conveying leaf 15 with variable diameter, the tung oil in Jatropha jatropha seed grains is squeezed out by the squeezing shaft 8, the screw conveying leaf 15 and the bolt 11 at the same time, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com