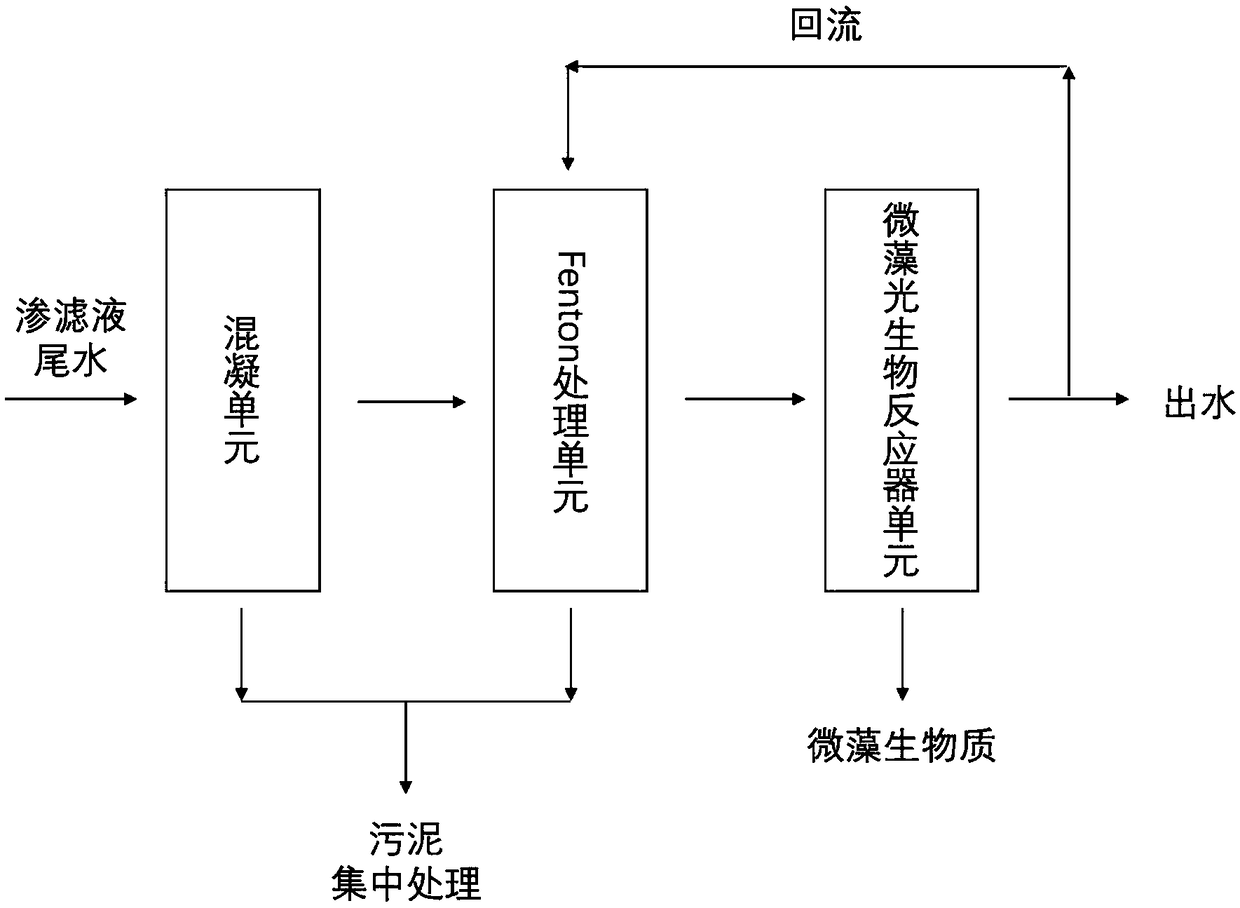

Treatment method of leachate tail water based on advanced oxidation combination technology

A combined process and advanced oxidation technology, which is applied in special compound water treatment, polluted groundwater/leachate treatment, water/sewage treatment, etc., can solve the problem of difficult treatment of dense phase liquid after the membrane, and achieve the goal of reducing treatment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The leachate ultrafiltration effluent of a waste incineration plant in Jiangsu is used as the influent of the coagulation unit. The water quality of the ultrafiltration effluent is roughly as follows: pH is about 6.6; COD concentration is 500-600 mg / L; ammonia nitrogen concentration is 20-40mg / L; the total nitrogen concentration is about 100-200mg / L; the total phosphorus concentration is about 2mg / L; the color is tea yellow, basically no odor.

[0043] The flocculant polymerized ferric sulfate and polyacrylamide were successively added to the ultrafiltration water, and the dosages were 0.5g / L and 1.5mg / L respectively. In the coagulation unit, first add polyferric sulfate and then fully stir for 10 minutes, then add polyacrylamide and continue stirring for 20 minutes, the mixed water is left to settle for about 30 minutes, and the layers are divided into supernatant liquid and lower layer of precipitation. The supernatant was adjusted to pH 3.5 by adding hydrochloric ac...

Embodiment 2

[0049] The leachate tail water of a waste incineration plant in Hefei is used as the influent of the coagulation unit. The water quality of the tail water is roughly as follows: pH is about 6.2-6.7; COD concentration is about 250mg / L; ammonia nitrogen concentration is 10-20mg / L ; The total nitrogen concentration is about 60mg / L; the total phosphorus concentration is about 2mg / L; the color is light brown and has no peculiar smell.

[0050] The leachate tail water was treated by the method in Example 1. During the test operation, the dosage of polyferric sulfate and polyacrylamide was 0.2g / L and 1mg / L respectively, and the pH of the supernatant was adjusted to 3.2 left and right; adjust FeSO 4 ·7H 2 The dosages of O and 30% hydrogen peroxide were 0.08% and 0.27% respectively, the reaction time of water in the Fenton oxidation unit was 2h, and the precipitation was allowed to stand for 1h. The pH of the supernatant was adjusted to about 6.7. The aeration rate of the microalgae ...

Embodiment 3

[0054] The leachate biochemical effluent of a waste incineration plant in Jiangsu is used as the influent of the coagulation unit. The water quality of the biochemical effluent is roughly as follows: pH is 6.5-6.9; COD concentration is about 1200mg / L; ammonia nitrogen concentration is 45-60mg / L; The total nitrogen concentration is about 300mg / L; the total phosphorus concentration is about 2.3mg / L.

[0055] The leachate biochemical effluent was treated by the method in Example 1. During the test operation, the dosage of polyferric sulfate and polyacrylamide was 1g / L and 2mg / L respectively, and the pH of the supernatant was adjusted to about 3. ; adjust FeSO 4 ·7H 2 The dosages of O and 30% hydrogen peroxide were 0.7% and 3% respectively, the reaction time of water in the Fenton oxidation unit was 3 hours, and the precipitation was allowed to stand for 1 hour. The pH of the supernatant was adjusted to about 6.6. The aeration rate of the microalgae photobioreactor unit is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com