Method and device for co-production of animal feed and biodiesel feedstock by using kitchen waste through hydrothermal treatment

A technology for kitchen waste and biodiesel, which is applied in the directions of animal feed, animal feed, biofuel, etc., can solve the problems such as the inability to realize the maximum resource utilization of kitchen waste, single product, and primary process, and achieve stable operation, high salt content, etc. Low, simple system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is a further description of the present invention, rather than a limitation of the present invention.

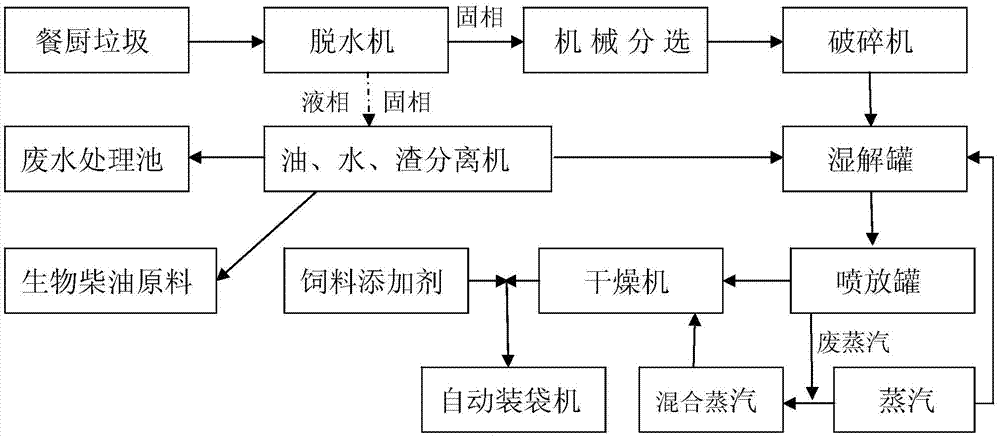

[0031] Such as figure 1 As shown, after the uniformly collected food waste enters the factory area, it is first mechanically extruded, filtered and dehydrated on the dehydrator to reduce the water content of solid phase waste to about 50%, and to obtain solid phase waste, liquid phase and solid phase doped Mixed-phase garbage; the separated solid-phase garbage enters the mechanical sorting section for sorting, sorting out unusable components such as plastic, metal and glass, and the available solid-phase garbage components are crushed in the crusher to make the size of the garbage Homogenize and enhance the dehydration performance of garbage; the crushed solid-phase garbage enters the hydrothermal dehydration tank for hydrolysis, and the saturated steam is heated to make the temperature reach 140℃~160℃, the pressure is 0.4~0.7MPa, and the reaction is mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com