Coarse grain biscuit and preparation method thereof

A technology for coarse grains and biscuits, applied in baking, baked goods, food science and other directions, can solve problems such as unsatisfactory taste, difficult to master the ratio of raw materials, and difficult to scale production, and achieve low production costs. , The product quality is stable and the taste is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

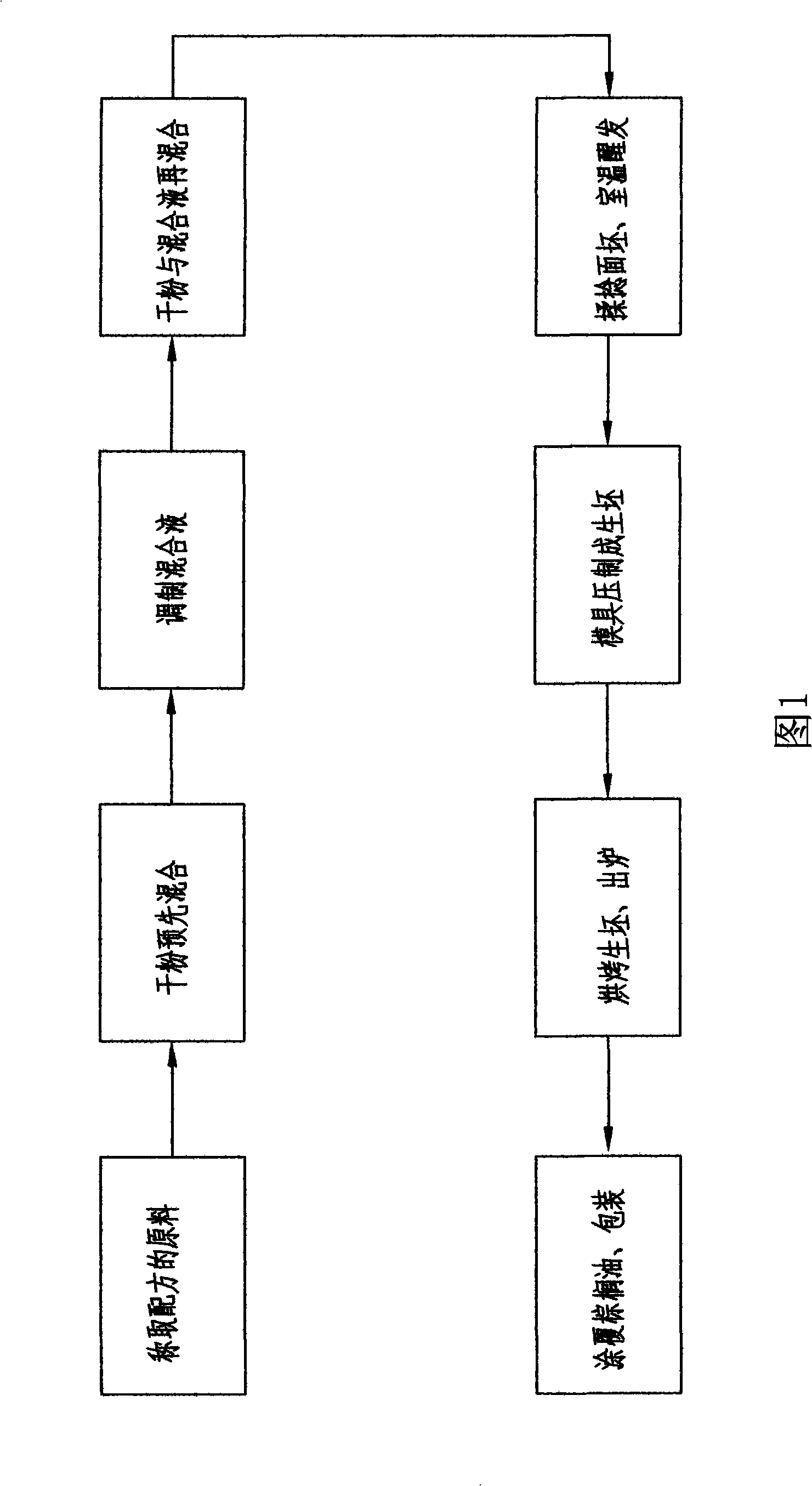

Image

Examples

Embodiment 1

[0041] 1. Take 15% of coarse grain flour processed from corn, buckwheat, sorghum, soybean, kidney bean, sweet potato, and yam, 38% of gluten flour, 10% of edible vegetable oil, 15% of white sugar, 2.5% of whole milk powder, bicarbonate 0.2% sodium, 0.35% ammonium bicarbonate, 0.2% edible salt, 0.15% coarse grain essence, 3% egg, appropriate amount of water.

[0042] 2. Pre-mix the dry powder first: mix and prepare the special coarse grain powder, gluten powder, and whole milk powder;

[0043] 3. Prepare the mixed solution: first heat the edible vegetable oil, then mix white sugar, edible salt, sodium bicarbonate, ammonium bicarbonate, coarse grain essence and water, and pour the well-mixed eggs into it to make a mixed solution; then put Pour the heated edible vegetable oil into the mixture;

[0044] 4. Add the prepared mixed liquid to the pre-mixed dry powder for re-mixing, and add appropriate amount of water to knead the dough as needed, and the amount of water added should ...

Embodiment 2

[0050] 1. Take 18% of coarse grain flour made from black rice, purple rice, barley, wheat bran, black beans, green beans, broad beans, peas, yams, and potatoes, 30% of gluten flour, 15% of edible vegetable oil, and 18% of white sugar , whole milk powder 3%, sodium bicarbonate 0.25%, ammonium bicarbonate 0.2%, edible salt 0.25%, whole grain essence 0.25%, egg 2.5%, water amount.

[0051] 2. With embodiment 1;

[0052] 3. With embodiment 1;

[0053] 4. With embodiment 1;

[0054] 5. Knead the dough for about 15 minutes and let it stand at room temperature for star hair;

[0055] 6. With embodiment 1;

[0056] 7. Send the green body into the oven to bake for about 15 minutes, and it will become the coarse grain biscuit of the present invention after it is released from the oven;

[0057] 8. Same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com