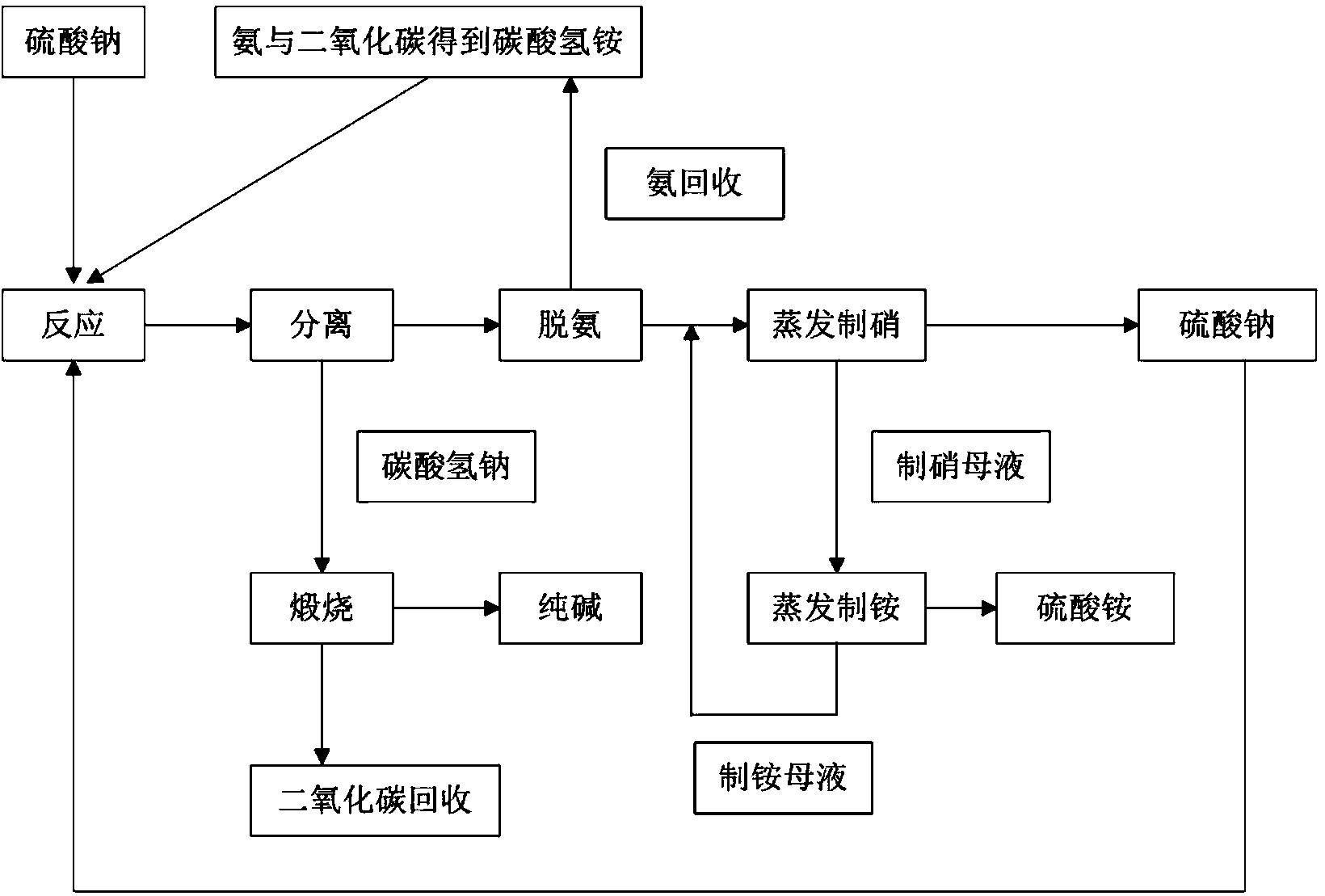

Thermal circulation technology of utilizing sodium sulfate solution or carrier to cogenerate sodium carbonate and ammonium sulfate

A technology of sodium sulfate solution and ammonium sulfate, applied in ammonium sulfate and carbonate preparations, etc., can solve the problems of high raw material cost, large circulation volume of ammonium precipitation mother liquor, and high power consumption of cold precipitation salt precipitation crystallization ammonium chloride , to achieve the effect of reducing energy consumption and cost, and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Take 100 tons of Na 2 SO 4 (contains Na 2 SO 4 100%) and ammonia (NH 3 ), carbon dioxide (CO 2 ) obtained 111.3 tons of ammonium bicarbonate (containing NH 4 HCO 3 100%) solution is raw material, and 50.0 tons of sodium sulfate (Na 2 SO 4 ) after the metathesis reaction (reaction temperature 25°C) was separated to obtain 118.2 tons of sodium bicarbonate (NaHCO 3 ) and 400m containing ammonium bicarbonate, ammonium sulfate, sodium sulfate and ammonium carbonate 3 Soda making mother liquor (Na 2 SO 4 125g / L, (NH 4 ) 2 SO 4 232.5g / L, NH 4 HCO 3 +(NH 4 ) 2 CO 3 95g / L), 400m 3 High temperature deamination of soda mother liquor (temperature 100°C) to obtain 380m 3 Deamination mother liquor (Na 2 SO 4 131.6g / L, (NH 4 ) 2 SO 4 244.7g / L), 380m 3 Deamination mother liquor and 532m 3 Ammonium making mother liquor (Na 2 SO 4 68g / L, (NH 4 ) 2 SO 4 442g / L) mixed with high-temperature evaporation (temperature 130°C) to obtain 50.0 tons of sodium sulfate...

Embodiment 2

[0072] Take 100 tons of Na 2 SO 4 (contains Na 2 SO 4 100%) and ammonia (NH 3 ), carbon dioxide (CO 2 ) obtained 111.3 tons of ammonium bicarbonate (containing NH 4 HCO 3 100%) solution is raw material, and 48.0 tons of sodium sulfate (Na 2 SO 4 ) after the metathesis reaction (reaction temperature 20°C) was separated to obtain 118.2 tons of sodium bicarbonate (NaHCO 3 ) and 400m containing ammonium bicarbonate, ammonium sulfate, sodium sulfate and ammonium carbonate 3 Soda making mother liquor (Na 2 SO 4 120g / L, (NH 4 ) 2 SO 4 225g / L, NH 4 HCO 3 +(NH 4 ) 2 CO 3 90g / L), 400m 3 High temperature deamination of soda mother liquor (temperature 110°C) to obtain 383.6m 3 Deamination mother liquor (Na 2 SO 4 125.1g / L, (NH 4 )2 SO 4 234.6g / L), 383.6m 3 Deamination mother liquor and 510.6m 3 Ammonium making mother liquor (Na 2 SO 4 68g / L, (NH 4 ) 2 SO 4 442g / L) mixed with high-temperature evaporation (temperature 130°C) to obtain 48.0 tons of sodium sulfa...

Embodiment 3

[0074] Take 100 tons of Na 2 SO 4 (contains Na 2 SO 4 100%) and ammonia (NH 3 ), carbon dioxide (CO 2 ) obtained 111.3 tons of ammonium bicarbonate (containing NH 4 HCO 3 100%) solution is raw material, and 52.0 tons of sodium sulfate (Na 2 SO 4 ) after the metathesis reaction (reaction temperature 30°C) was separated to obtain 118.2 tons of sodium bicarbonate (NaHCO 3 ) and 400m containing ammonium bicarbonate, ammonium sulfate, sodium sulfate and ammonium carbonate 3 Soda making mother liquor (Na 2 SO 4 130g / L, (NH 4 ) 2 SO 4 235g / L, NH 4 HCO 3 +(NH 4 ) 2 CO 3 100g / L), 400m 3 High temperature deamination of soda mother liquor (temperature 105°C) to obtain 381.8m 3 Deamination mother liquor (Na 2 SO 4 125.1g / L, (NH 4 ) 2 SO 4 234.6g / L), 381.8m 3 Deamination mother liquor and 553.2m 3 Ammonium making mother liquor (Na 2 SO 4 68g / L, (NH 4 ) 2 SO 4 442g / L) mixed with high-temperature evaporation (temperature 130°C) to obtain 52.0 tons of sodium su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com