Coking wastewater treatment method

A technology of coking wastewater and treatment methods, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of high energy consumption, high cost of flue gas desulfurization, secondary pollution and material recycling Insufficient utilization and other issues to achieve the effects of improving the environment, suitable for promotion, and reducing chemical agents and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

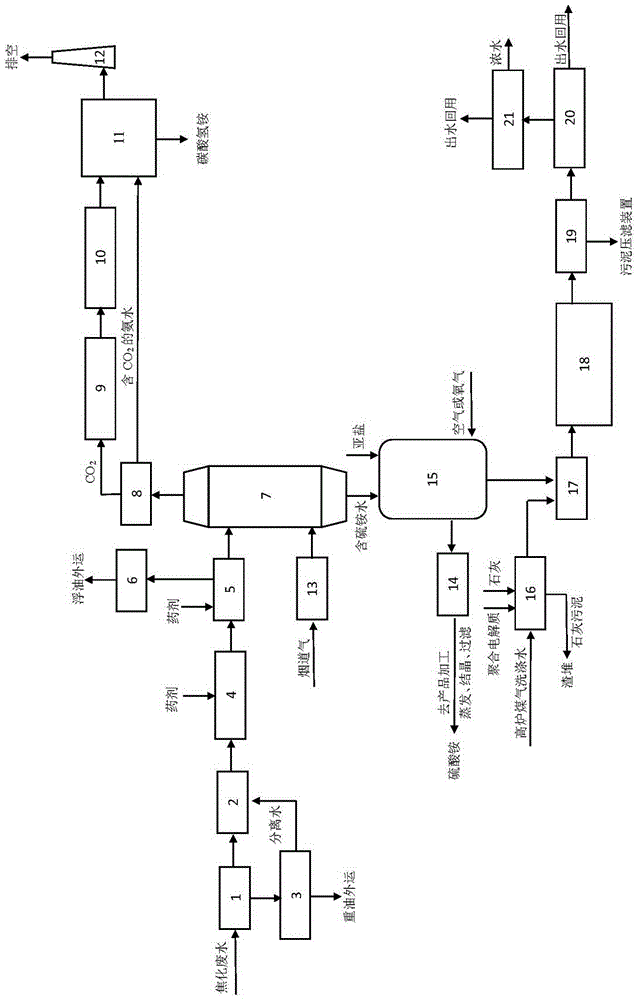

[0072] A coking wastewater treatment method, characterized in that it comprises the following steps:

[0073] (1) Pretreatment section

[0074] First remove the light oil and heavy oil in the coking wastewater, mix with the separated water after separating the heavy oil, then add coagulant and other agents, and then reduce the ammonia nitrogen in the coking wastewater and remove the slick oil, the treated coking wastewater and the smoke after dedusting The flue gas is contacted in countercurrent, and the sulfur-containing ammonium water generated after the reaction is oxidized to ammonium sulfate under the action of nitrite and air or other oxygen-containing gases, from which ammonium sulfate is extracted, and CO containing water is extracted from the reacted flue gas 2 of ammonia.

[0075] (2) Biological contact oxidation section

[0076] The coking wastewater treated in the pretreatment section is mixed with blast furnace gas washing water pretreated by polymerization and ...

Embodiment 2

[0080] A coking wastewater treatment method, characterized in that it comprises the following steps:

[0081] (1) Pretreatment section

[0082] The coking wastewater from coking, gas purification, and chemical product refining processes first passes through the grease trap 1 to remove light oil and heavy oil in the coking wastewater, and the coking wastewater after oil separation treatment enters the regulating tank 2 and is separated from the oil and water The separated water after the heavy oil is separated by the device 3 is mixed, and then enters the mixing reaction tank 4, and coagulant and other chemicals are added to the mixing reaction tank 4, and then enters the air flotation tank 5, and the chemical (coagulation agent) is added to the air flotation tank 5 to reduce coking Ammonia nitrogen in the wastewater is removed from the slick oil, and the slick oil collected by the oil collection tank 6 is transported outside. The coking waste water after oil separation and ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com