Process and system for capturing carbon dioxide from a gas stream

A carbon dioxide, gas flow technology, applied in chemical instruments and methods, separation methods, preparation of carbonate/acid carbonate, etc., can solve problems such as difficulty in ammonia recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0171] Preparation of Ammonium Chloride

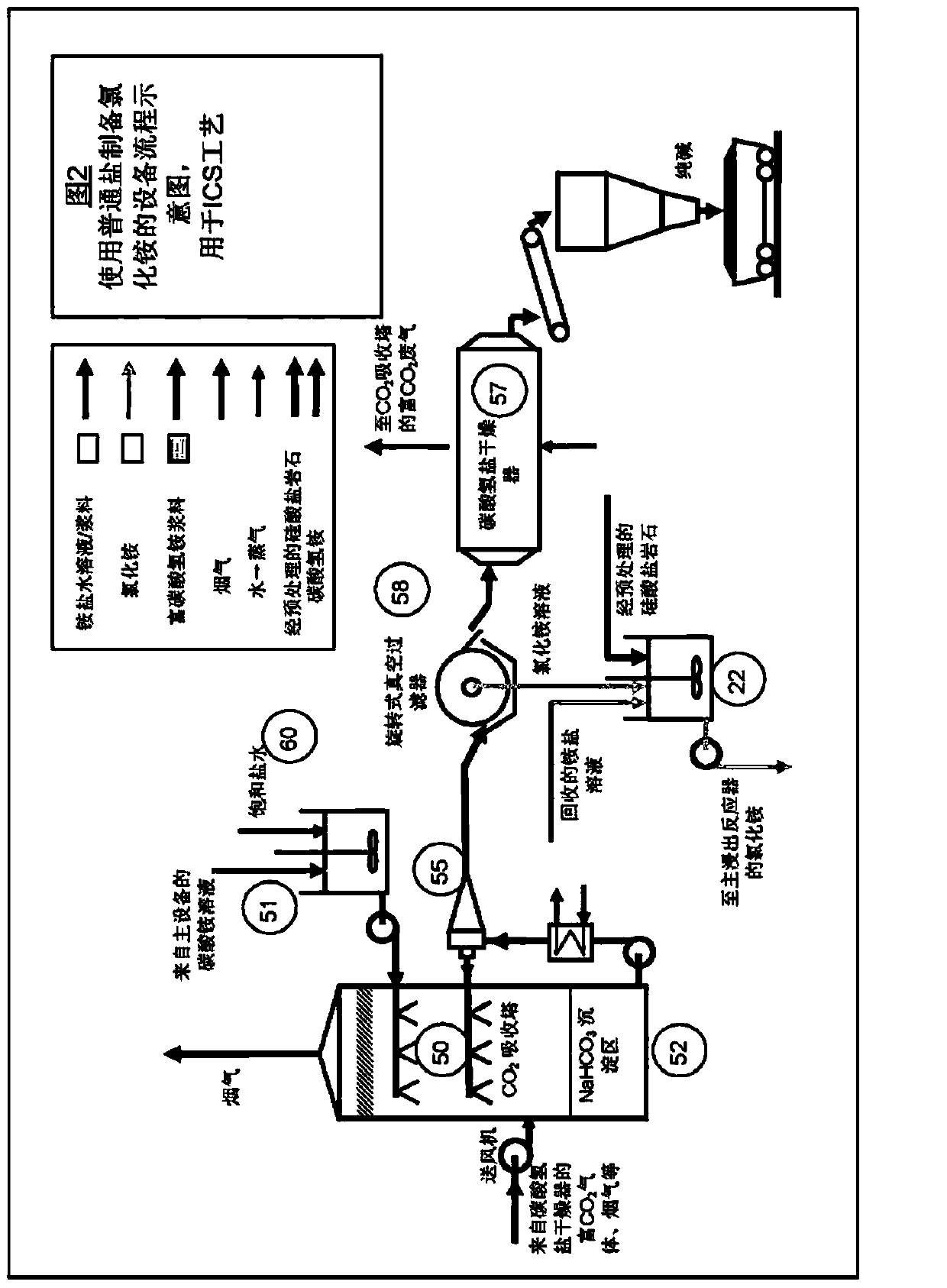

[0172] The amount of ammonium chloride required to make up for all the anions lost in the final carbonate mineral can be calculated according to figure 2 The described method is prepared from brine.

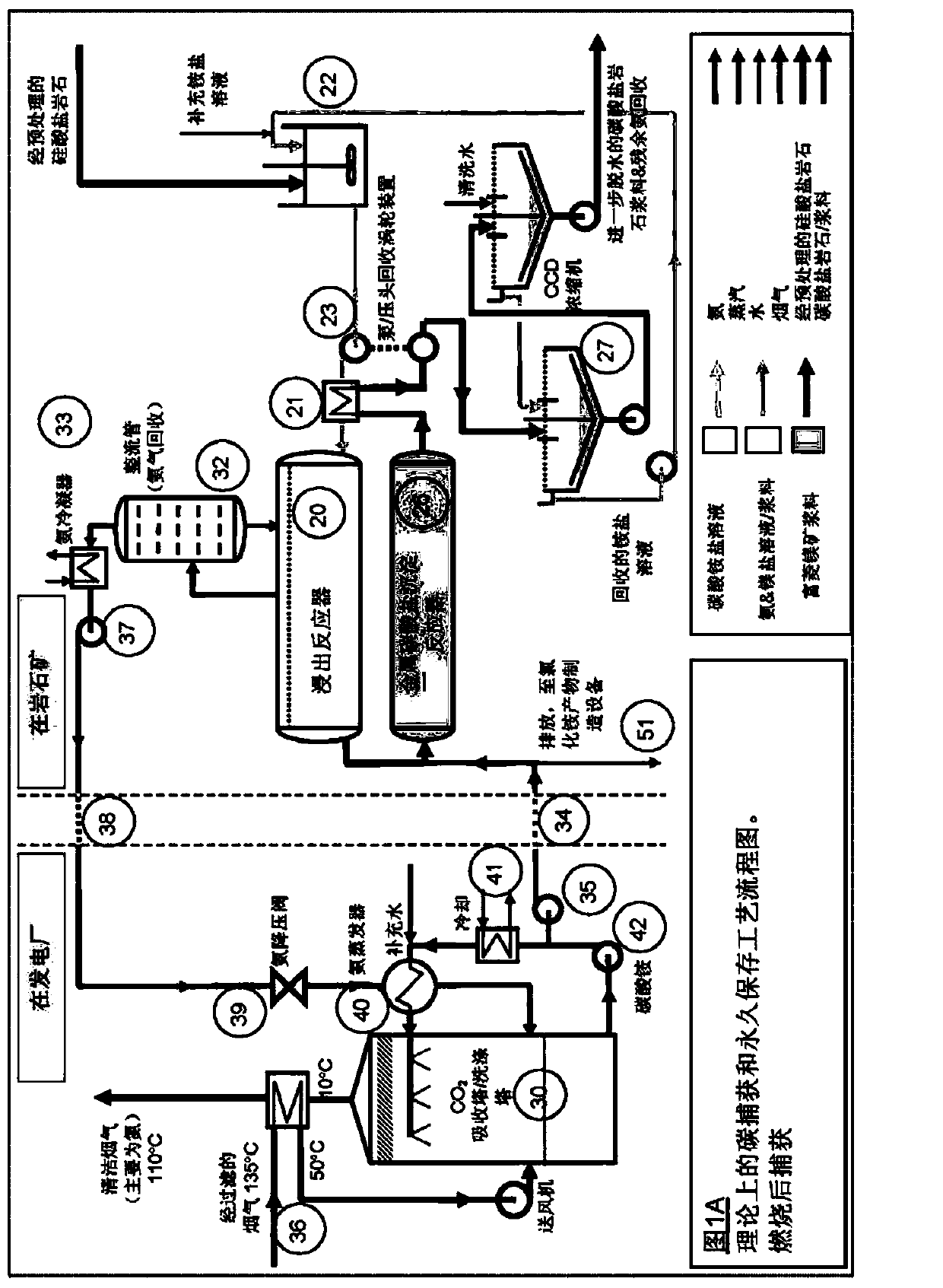

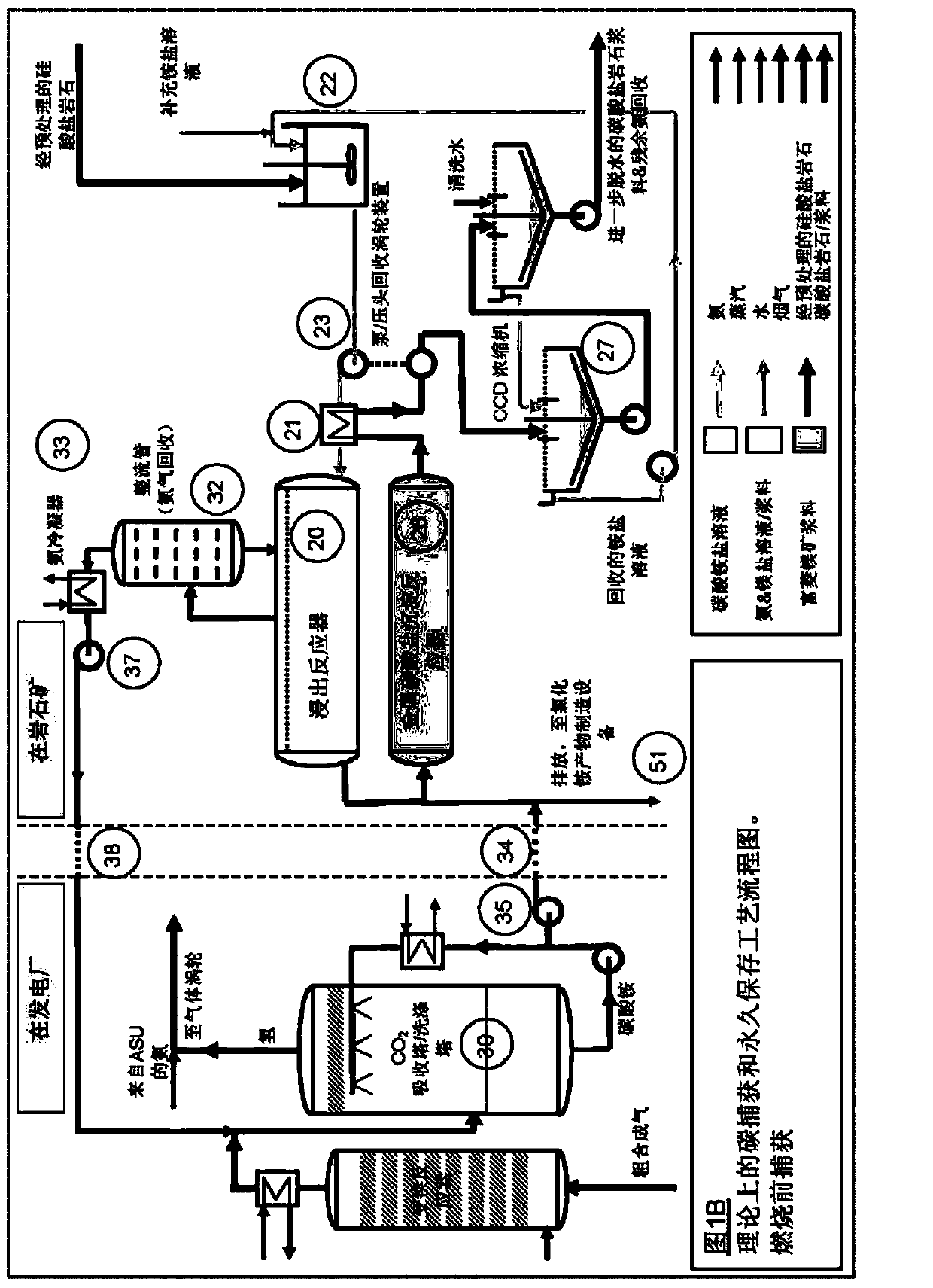

[0173] figure 2 The method shown is very similar to that used for the preparation of sodium bicarbonate (NaHCO 3 ), the ammonia-base or Solvay process has been used commercially for over 150 years. However, when applied to method 100, such as figure 2 As indicated, combine saturated or nearly saturated sodium chloride brine with Figure 1A and 1B The main circulation stream shown is mixed with an appropriate amount of ammonium carbonate solution 51 discharged. This mixture is used as CO 2 Absorption tower 50 (which is similar to Figure 1A CO in 2 The scrubbing medium in the absorption tower 30). Carbon dioxide obtained first from the decomposition of sodium bicarbonate in the bicarbonate dryer 57, if necessary by flue gas emis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com