Patents

Literature

32results about How to "Will not bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

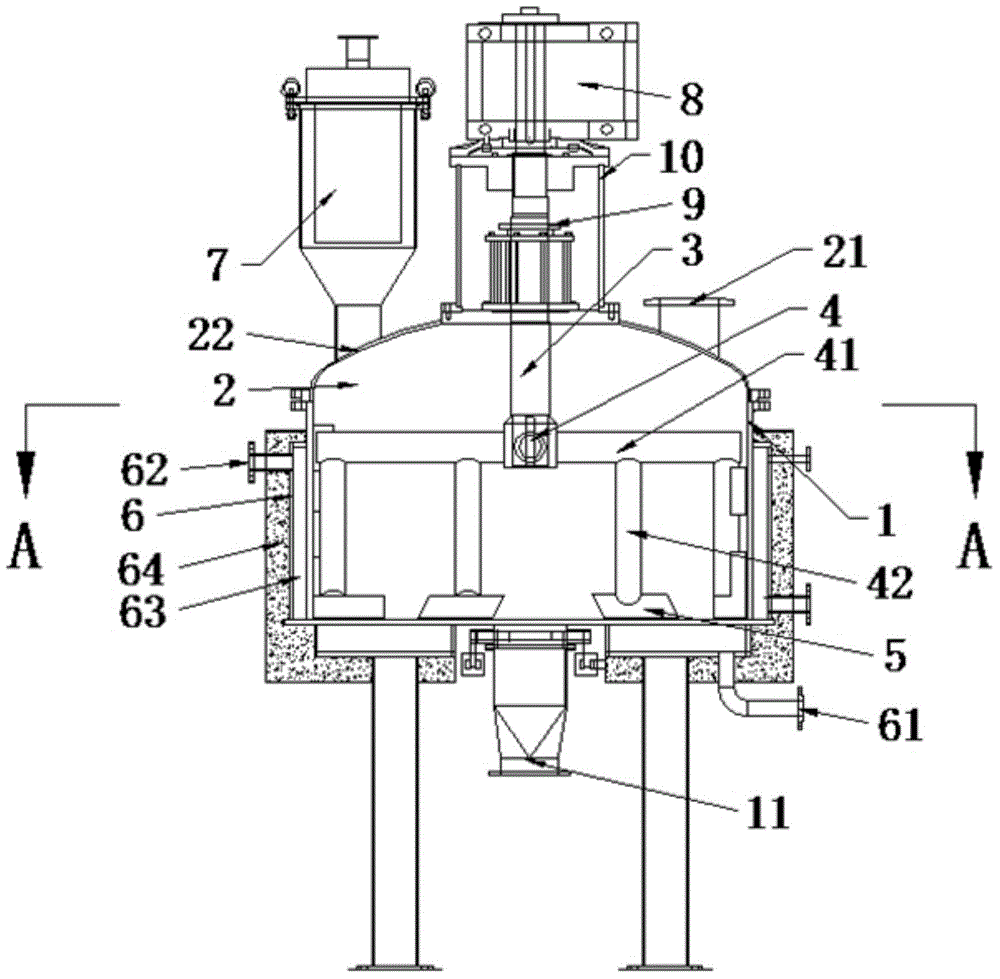

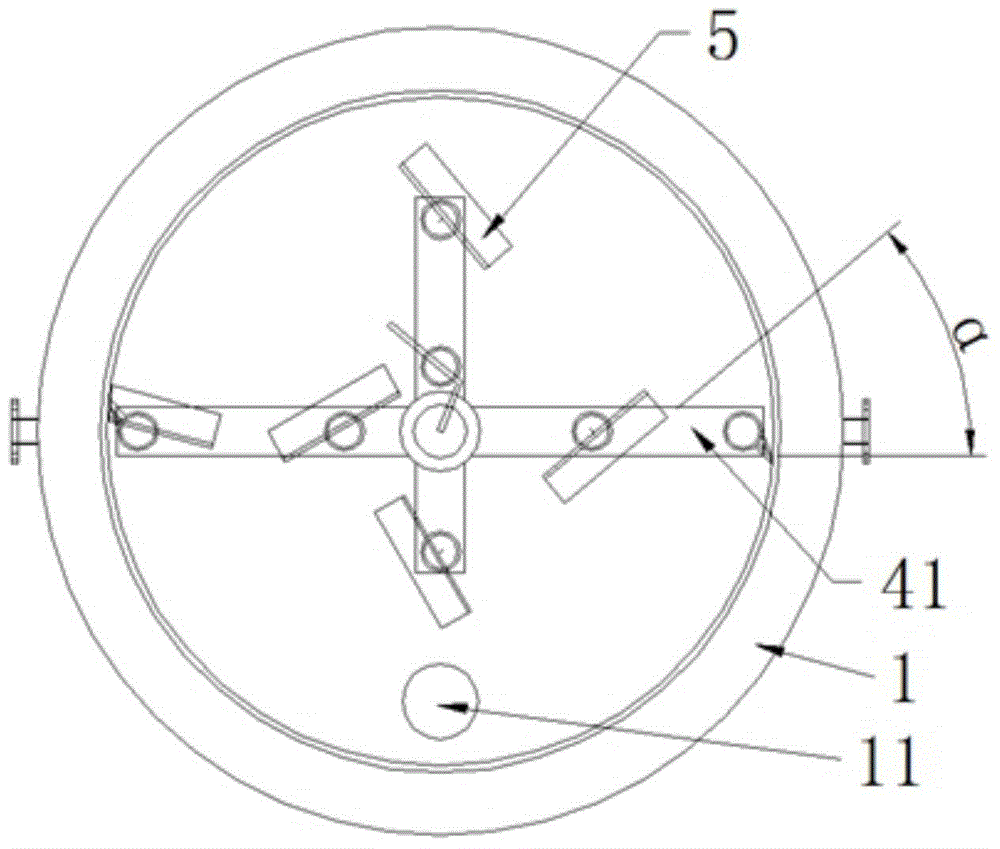

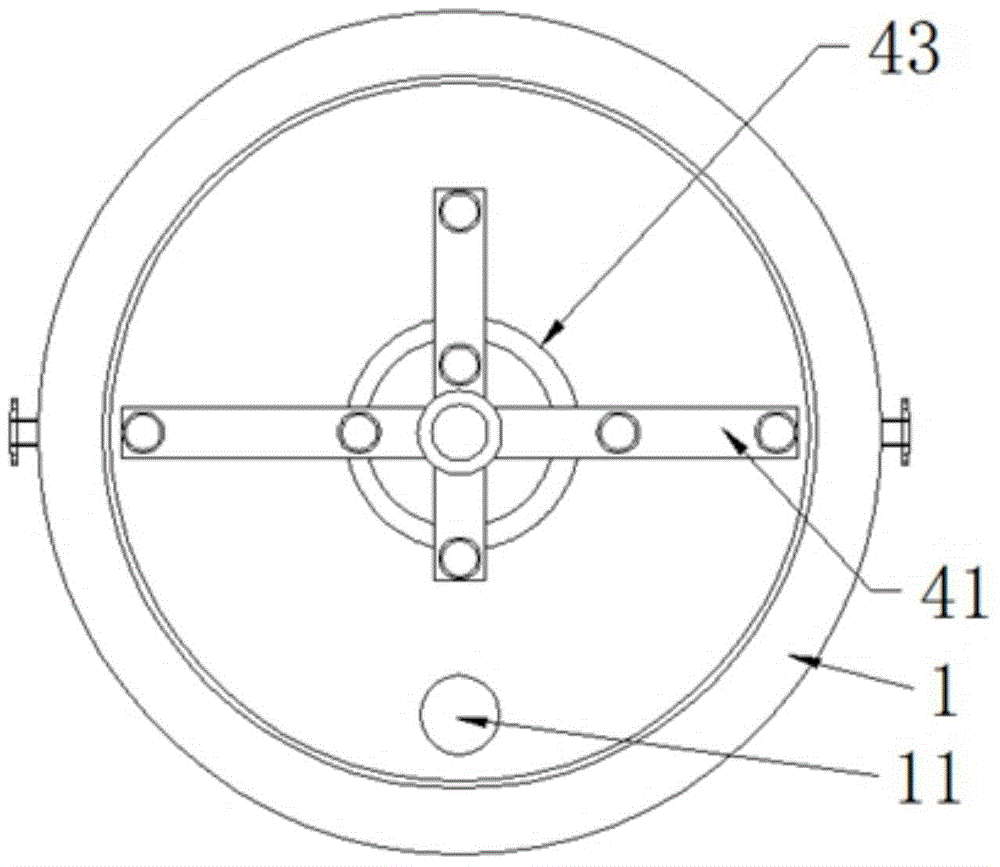

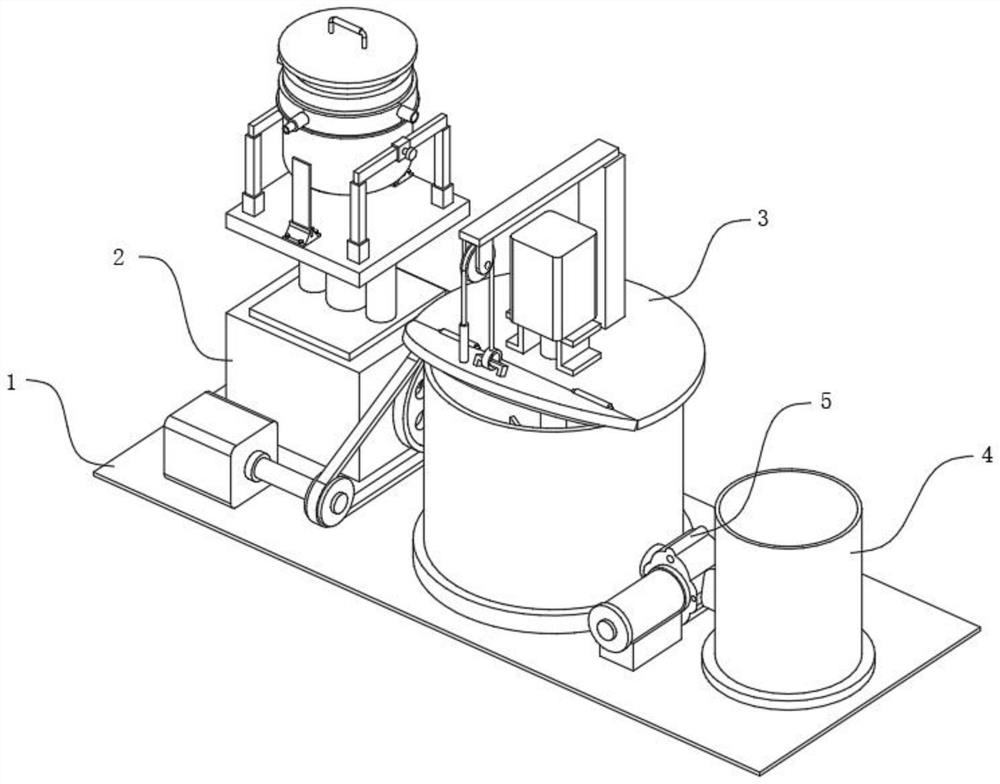

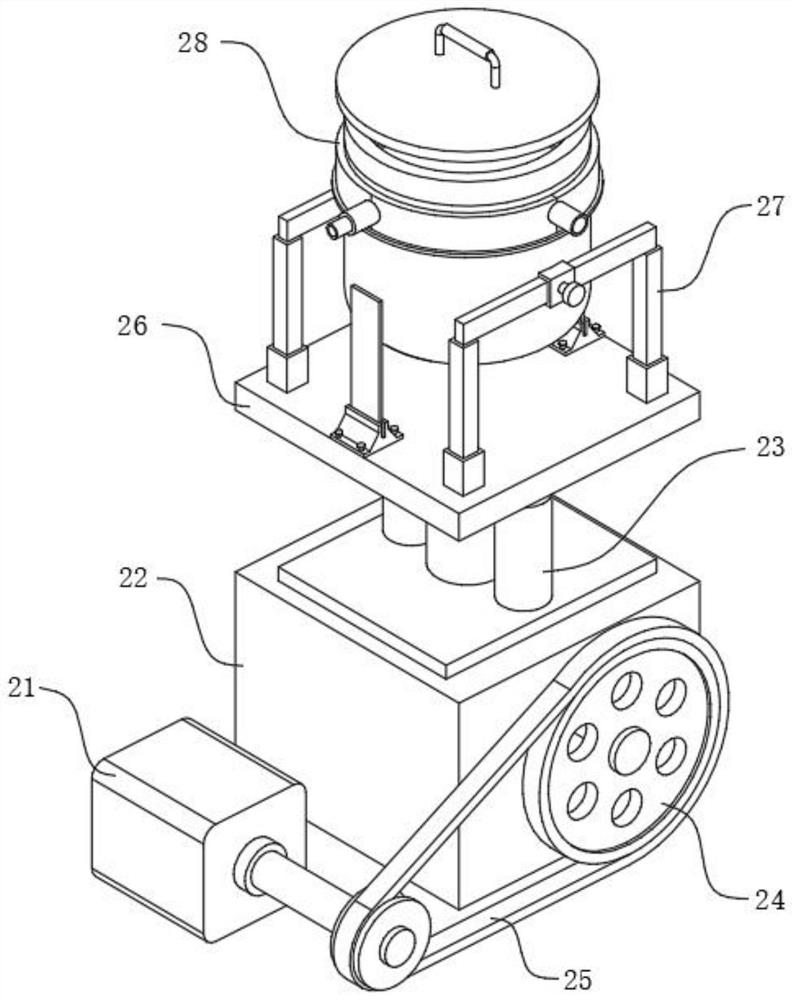

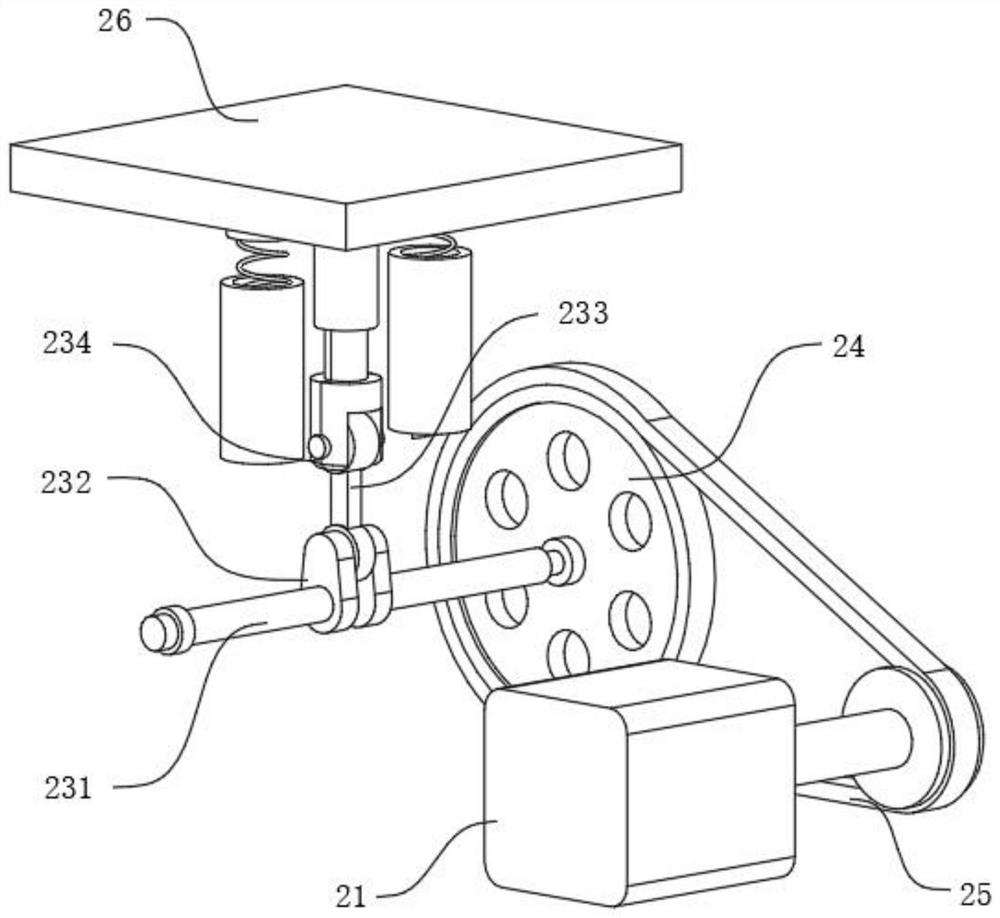

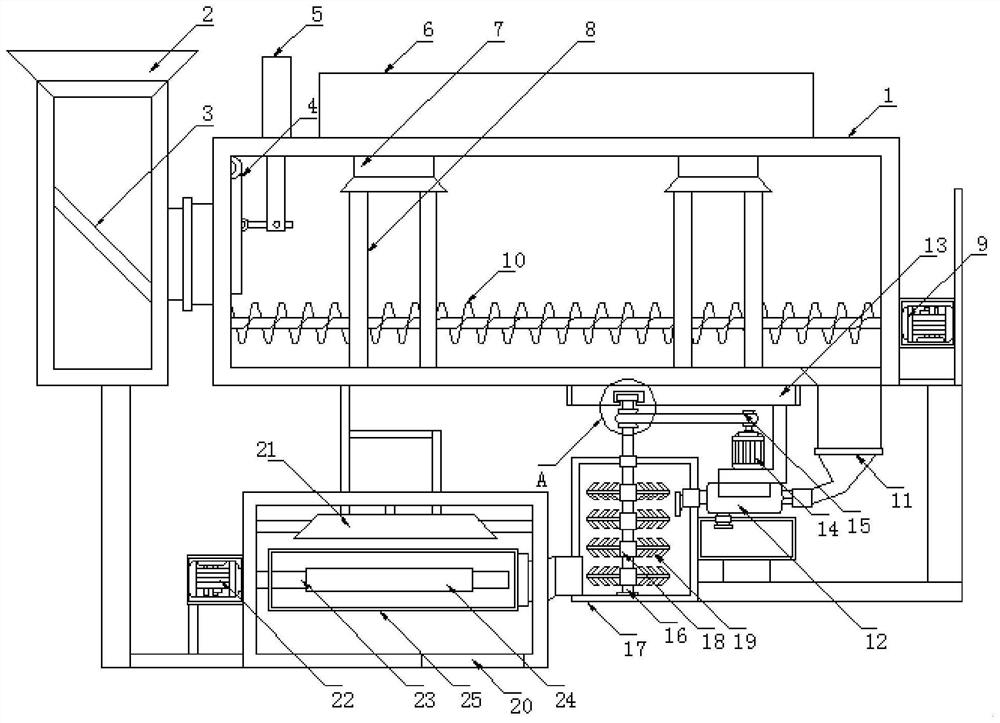

Stirring vacuum drying machine of scraping plate

InactiveCN104359292AEasy to launchGood adhesionDrying chambers/containersDrying machines with non-progressive movementsEngineeringPulp and paper industry

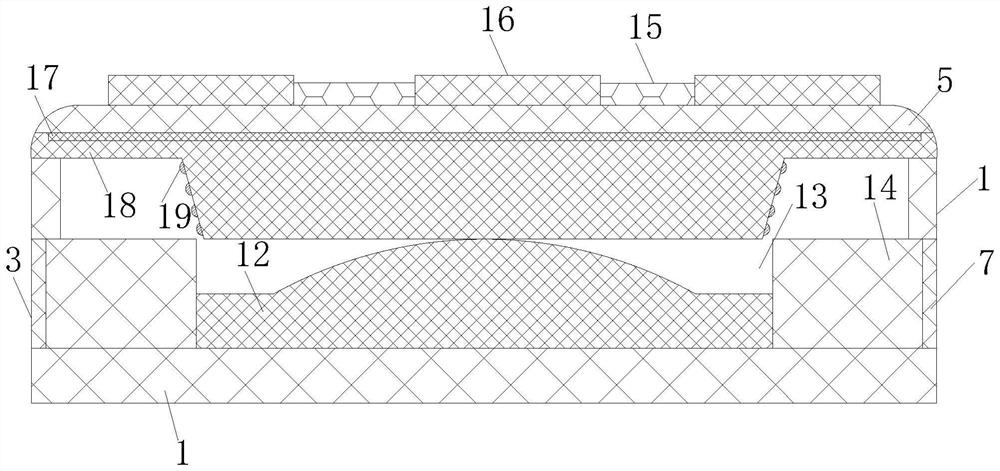

The invention relates to a stirring vacuum drying machine of a scraping plate. The stirring vacuum drying machine comprises an upright cylinder, a stirring device, an evacuating device and a heating device, wherein the upright cylinder is of a separated structure and comprises a cylinder body and a cylinder cover, wherein the cylinder body is provided with a closed end, an opened end and a side wall; a material outlet is formed in the place, close to the side wall, on the closed end; the cylinder cover covers the opened end; a material inlet and an evacuating opening are formed in the cylinder cover; the stirring device is formed by sequentially connecting a driving mechanism, a main shaft, a stirring frame and the scraping plate; the main shaft penetrates through the cylinder cover to extend into the cylinder body; the stirring frame is arranged at the lower end of the main shaft; the scraping plate is arranged at the lower end of the stirring frame; the evacuating device is arranged at the evacuating opening; the heating device wraps the cylinder body. According to the stirring vacuum drying machine, due to the fact that the material outlet is directly formed in the closed end of the cylinder body and is close to the side wall, the scraping plate just pushes dried materials to the place, close to the side wall, of the closed end, and the materials move along the scraping plate, the materials are very easily pushed out of the material outlet, and the stirring vacuum drying machine is simple, feasible and quick in operation; due to the fact that the materials are not stuck to the inside of the cylinder body, the materials are completely discharged.

Owner:CHANGZHOU YIBU DRYING EQUIP

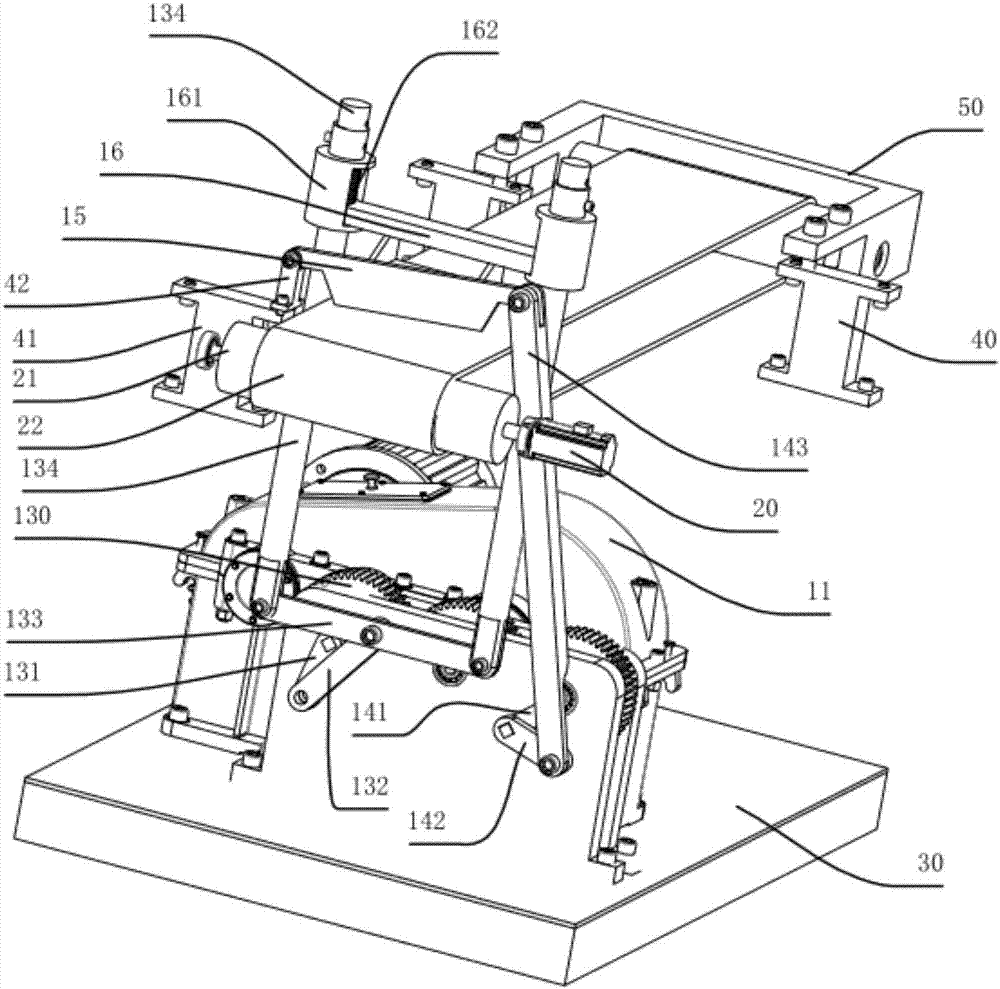

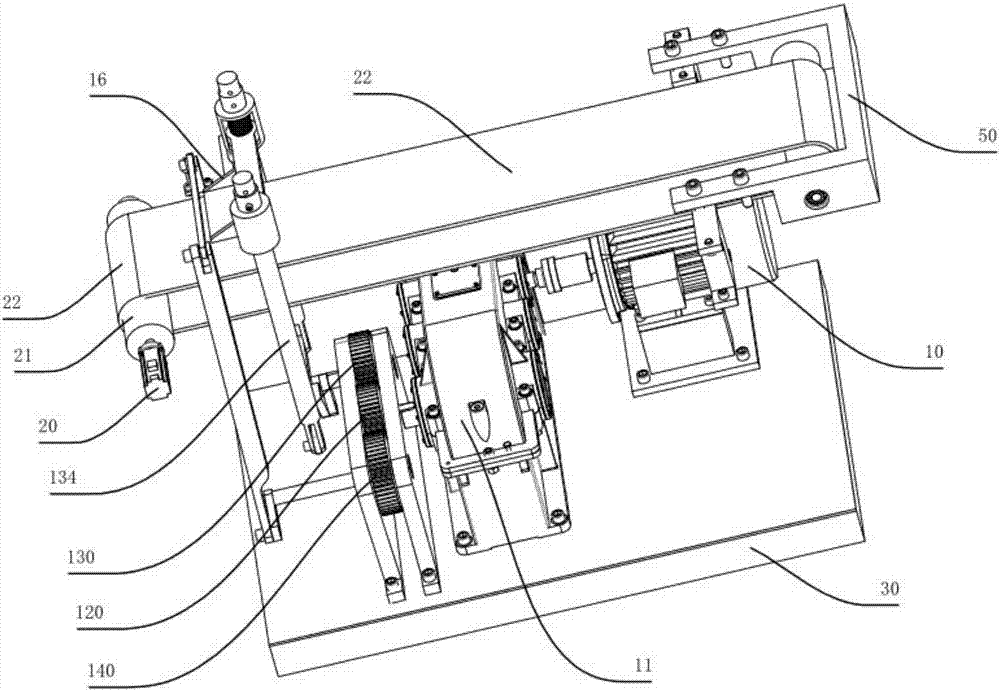

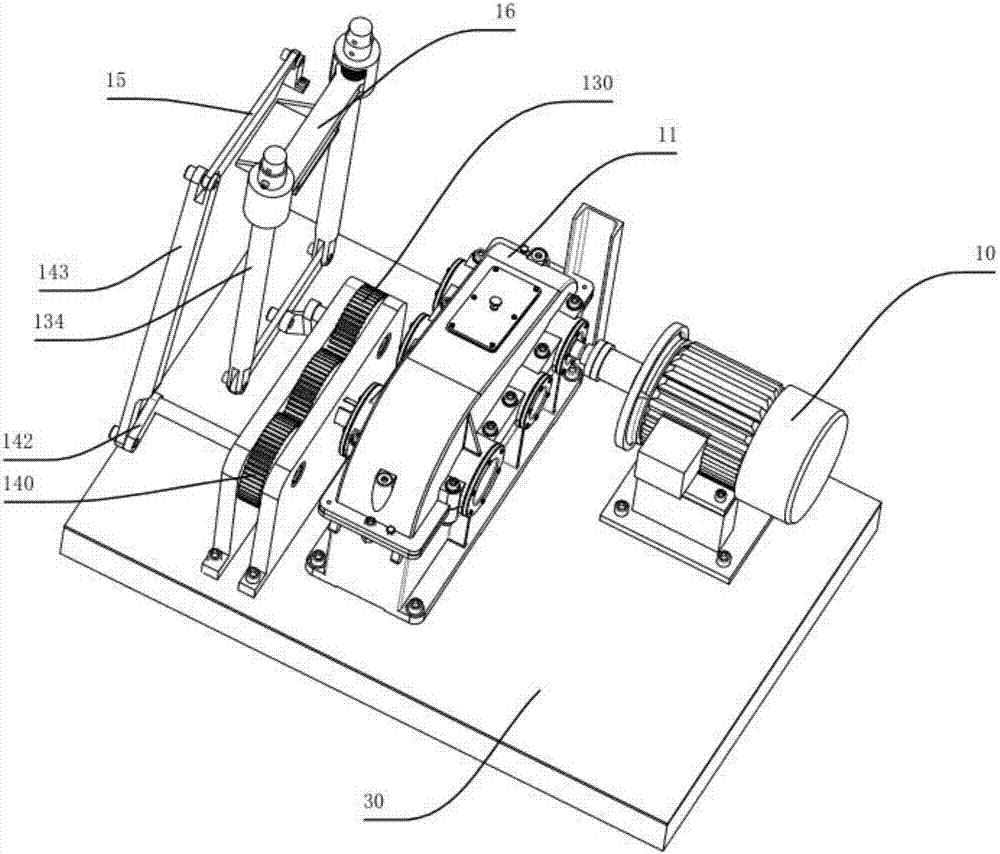

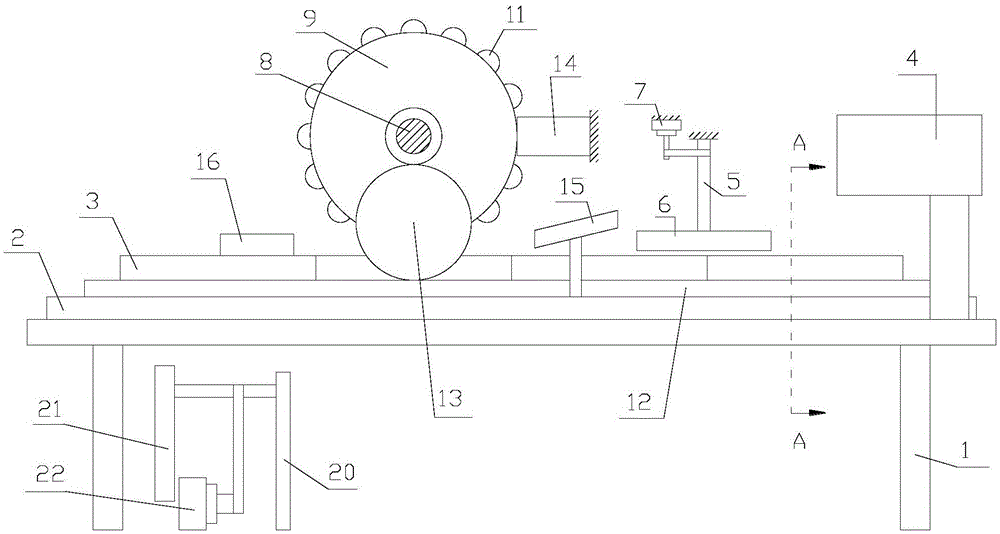

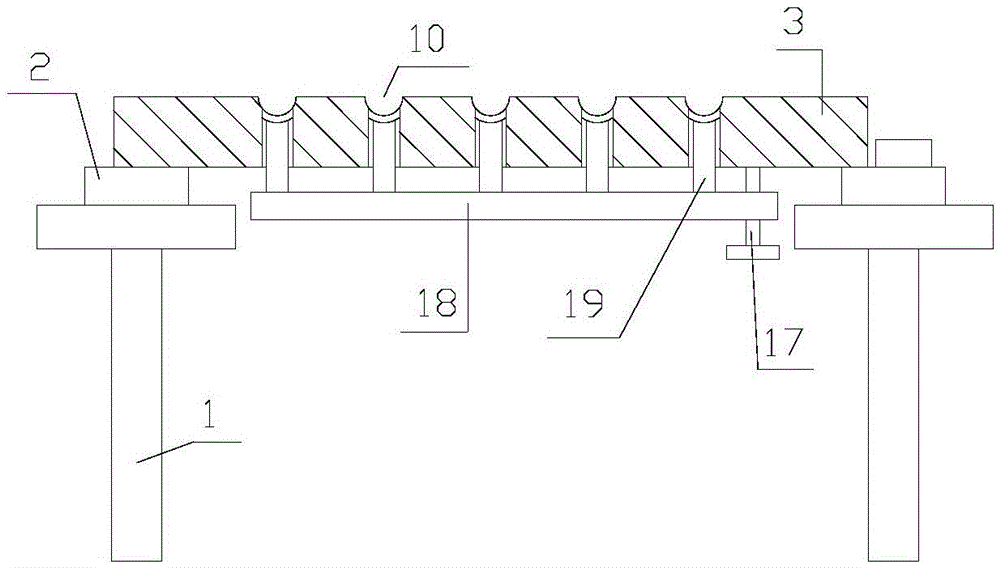

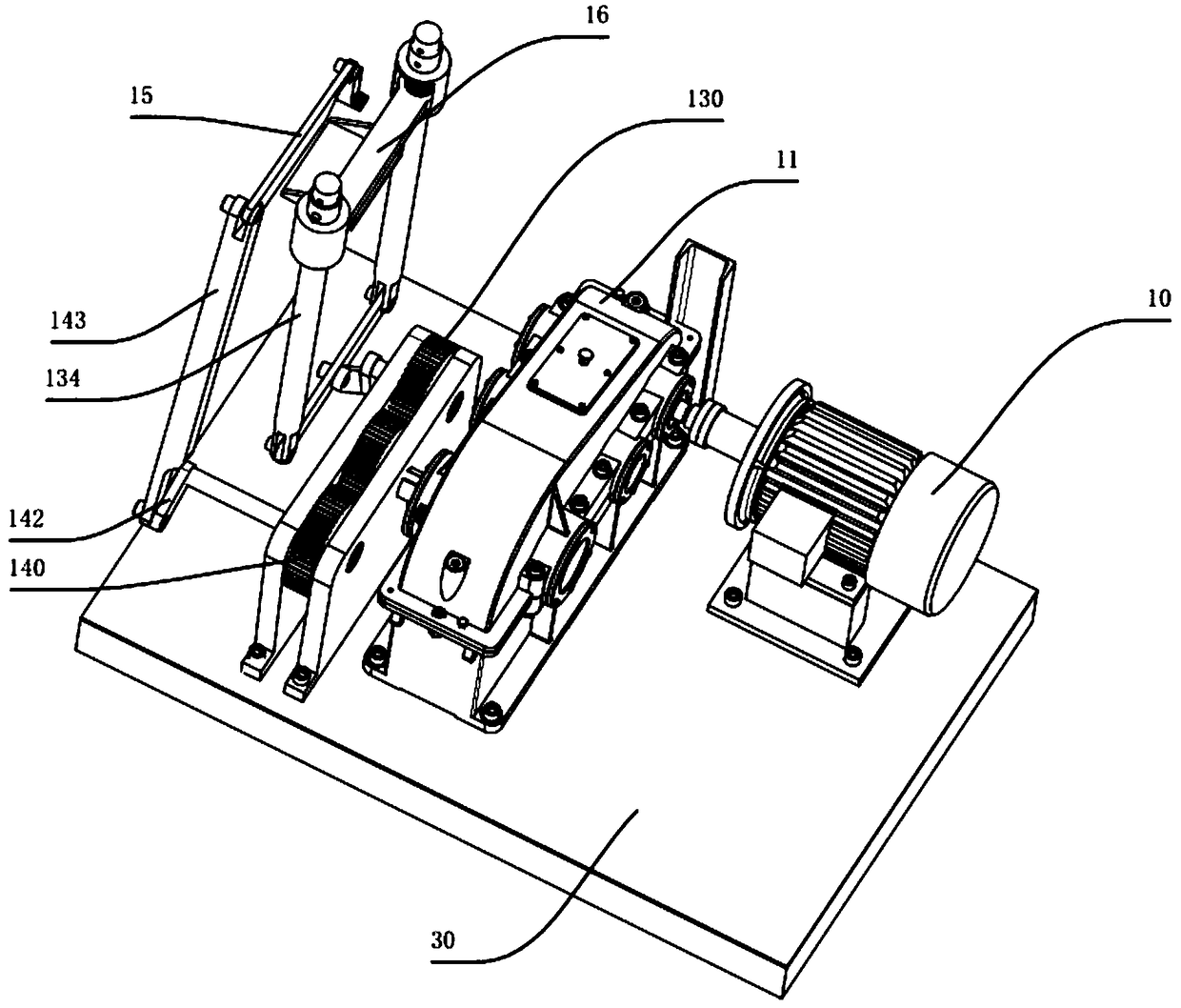

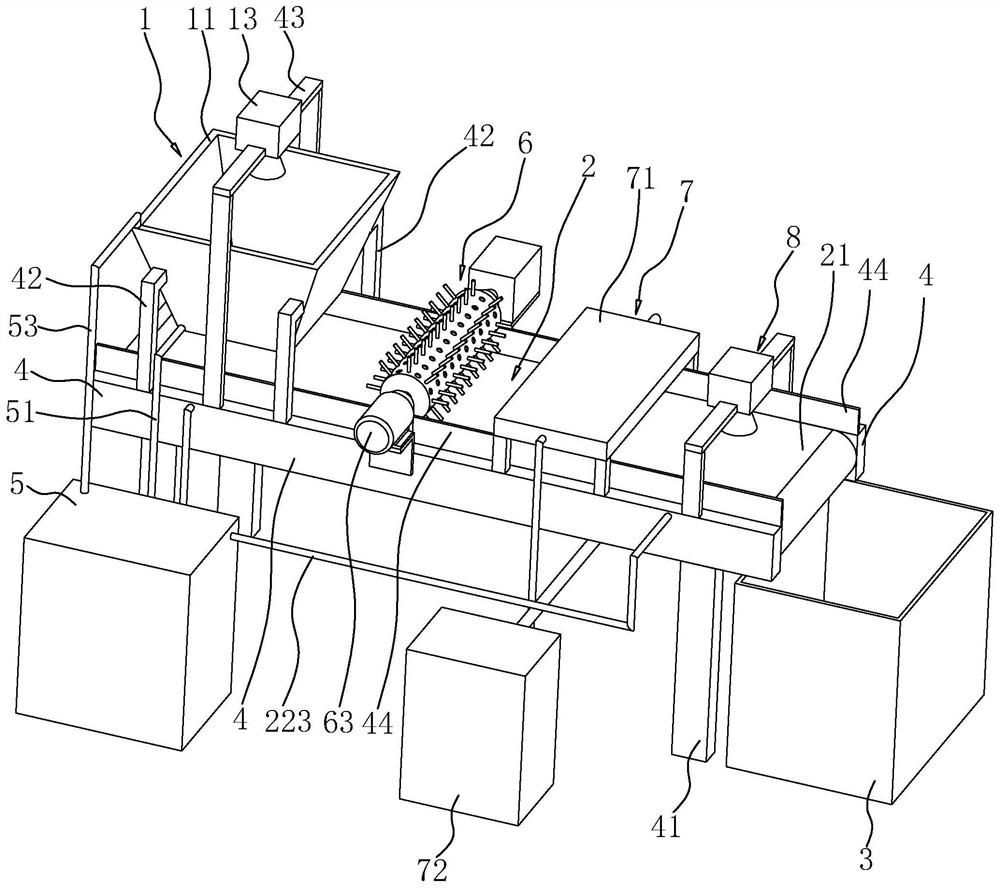

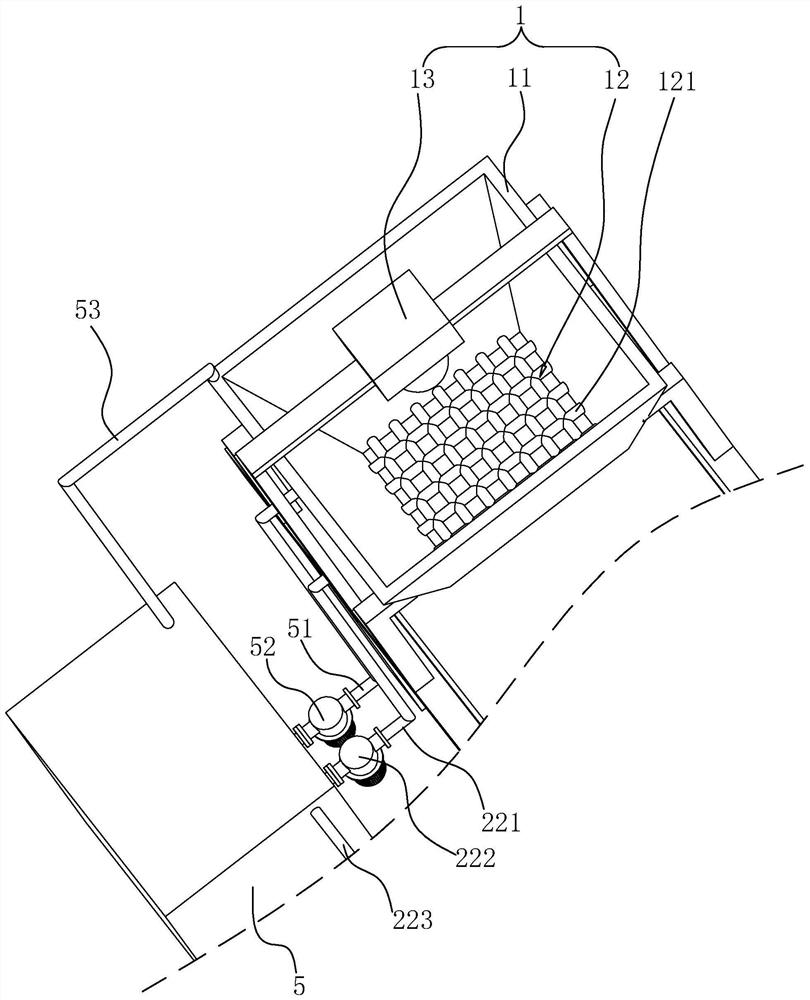

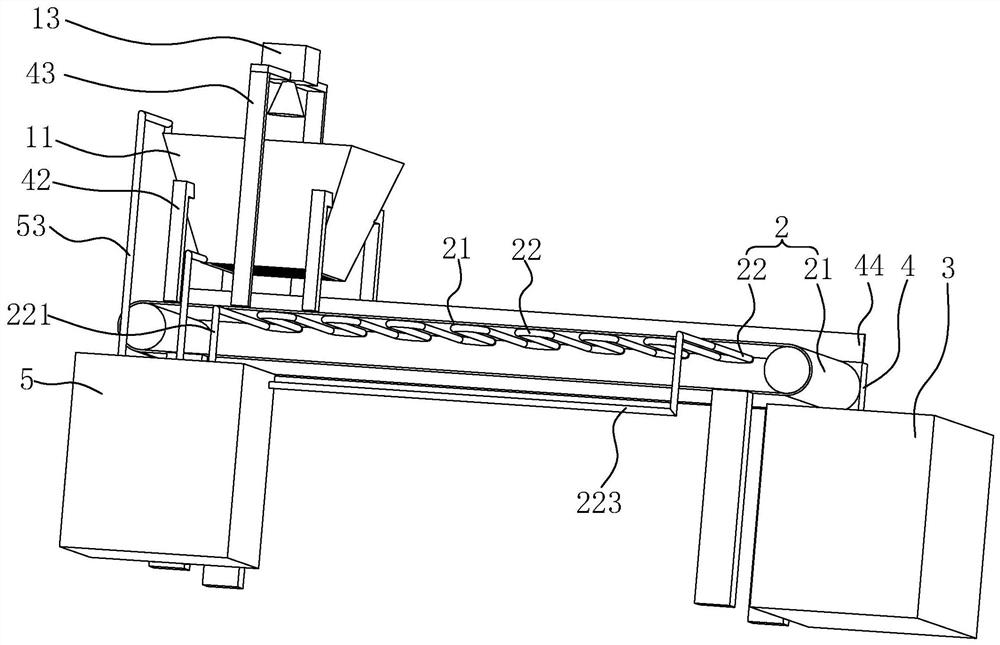

Rice cake slicing machine

ActiveCN106863389ATime-consuming and laborious to solveWill not bondMetal working apparatusEngineeringLinkage concept

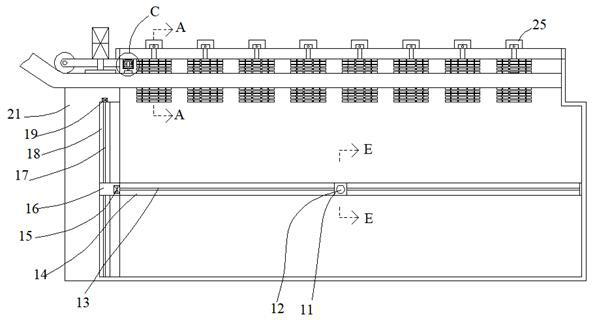

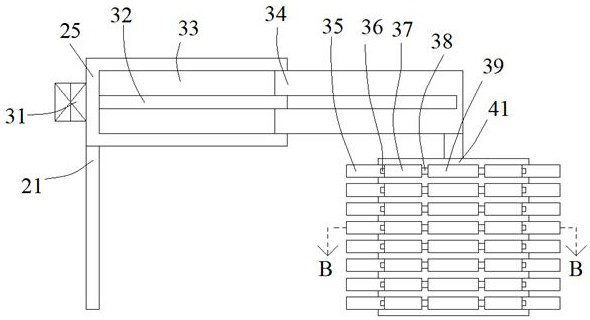

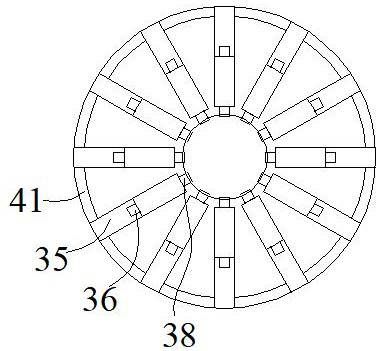

The invention proposes a rice cake slicing machine. The rice cake slicing machine comprises a cake slicing blade, a cake slicing blade driving device, a rice cake conveying belt, a rice cake slice receiving device and a rice cake slice receiving device lifting driving linkage piece, wherein the cake slicing blade is used for uniformly cutting strip-shaped rice cakes transferred along the rice cake conveying belt as rice cake slices; the rice slicing blade driving device is used for driving the cake slicing blade to perform the cutting and return reciprocating operations perpendicular to the strip-shaped rice cakes transferred along the rice cake conveying belt; and the rice cake slice receiving device is used for receiving the rice cake slices uniformly cut by the cake slicing blade on the rice cake conveying belt and conveying the rice cake slices for packing or storage. The rice cake slicing machine effectively solves such problems as time and labor wastes, nonuniform thickness and easiness in finger injury during cutting of rice cakes by kitchen knives, and can timely receive the rice cake slices through the rice cake slice receiving device for conveying to effectively prevent the integral bonding phenomenon caused by mutual extrusion of the adjacent rice cake slices.

Owner:辽宁走走进口食品贸易有限公司

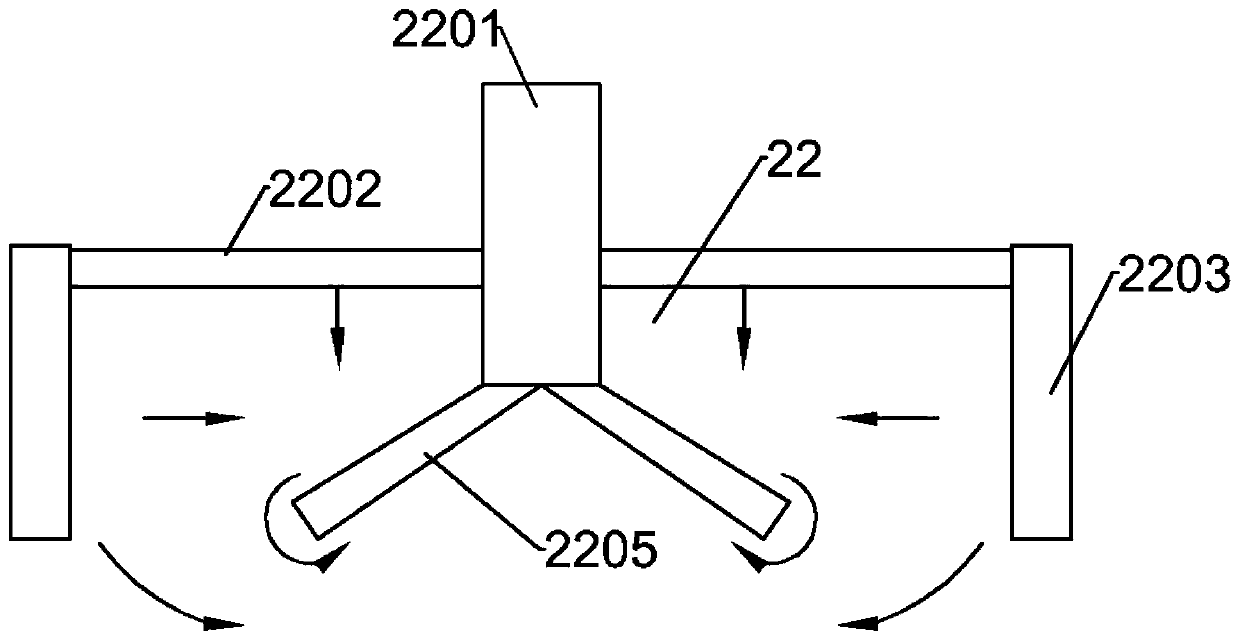

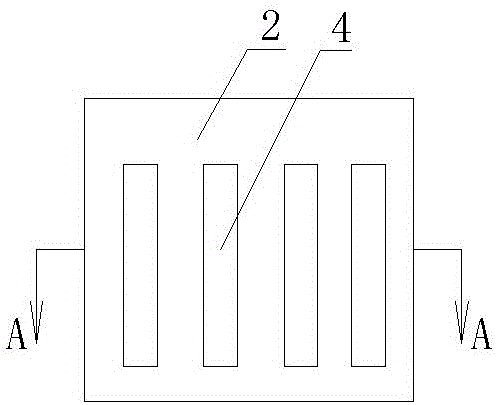

Granulating device

The invention discloses a granulating device. The granulating device comprises a support frame, a sliding plate, a plurality of supporting plates, a feeding box, a rotating shaft, a rotating plate, a first power unit, a supporting shaft, a pressure roll and a driving mechanism, wherein a guide rail is horizontally arranged on the support frame, the sliding plate is movably arranged on the guide rail, the plurality of supporting plates are arranged on the sliding plate and are distributed in a length direction of the guide rail, a plurality of grooves are formed on the upper surface of each supporting plate, the feeding box is arranged above the supporting plate, and a feeding hole and a discharging hole are formed on the feeding box; in a moving direction of the sliding plate, the rotating shaft is positioned at the downstream side of the feeding box, is positioned above the supporting plate and is arranged vertically; the rotating plate is arranged above the supporting plate and is installed on the rotating shaft, and a distance is preset between the rotating plate and the supporting plate; and the first power unit is used for driving the driving shaft to rotate. According to the granulating device, the materials are non-sticky, and the granulating effect is good.

Owner:WUHU 36 MACHINERY

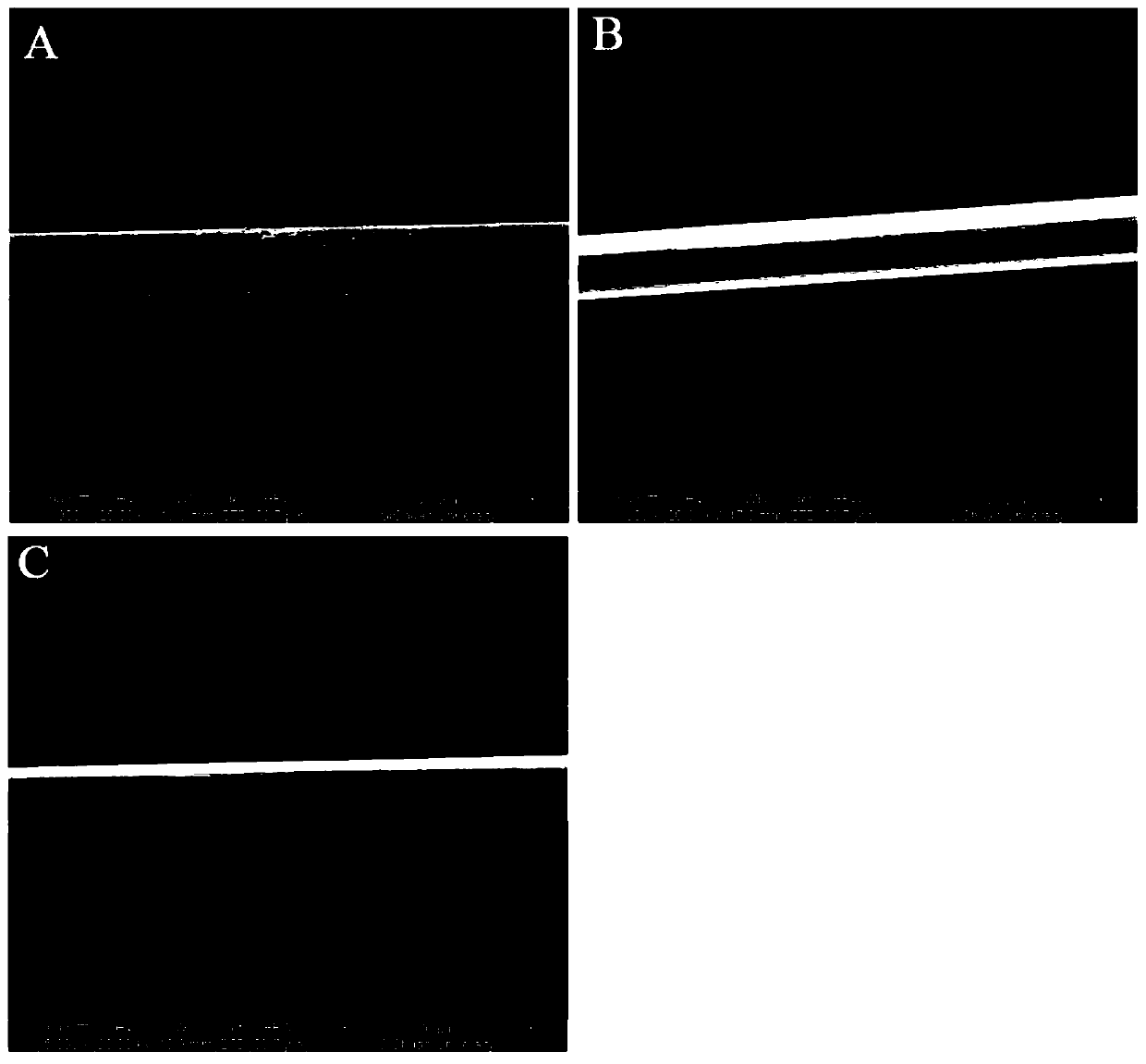

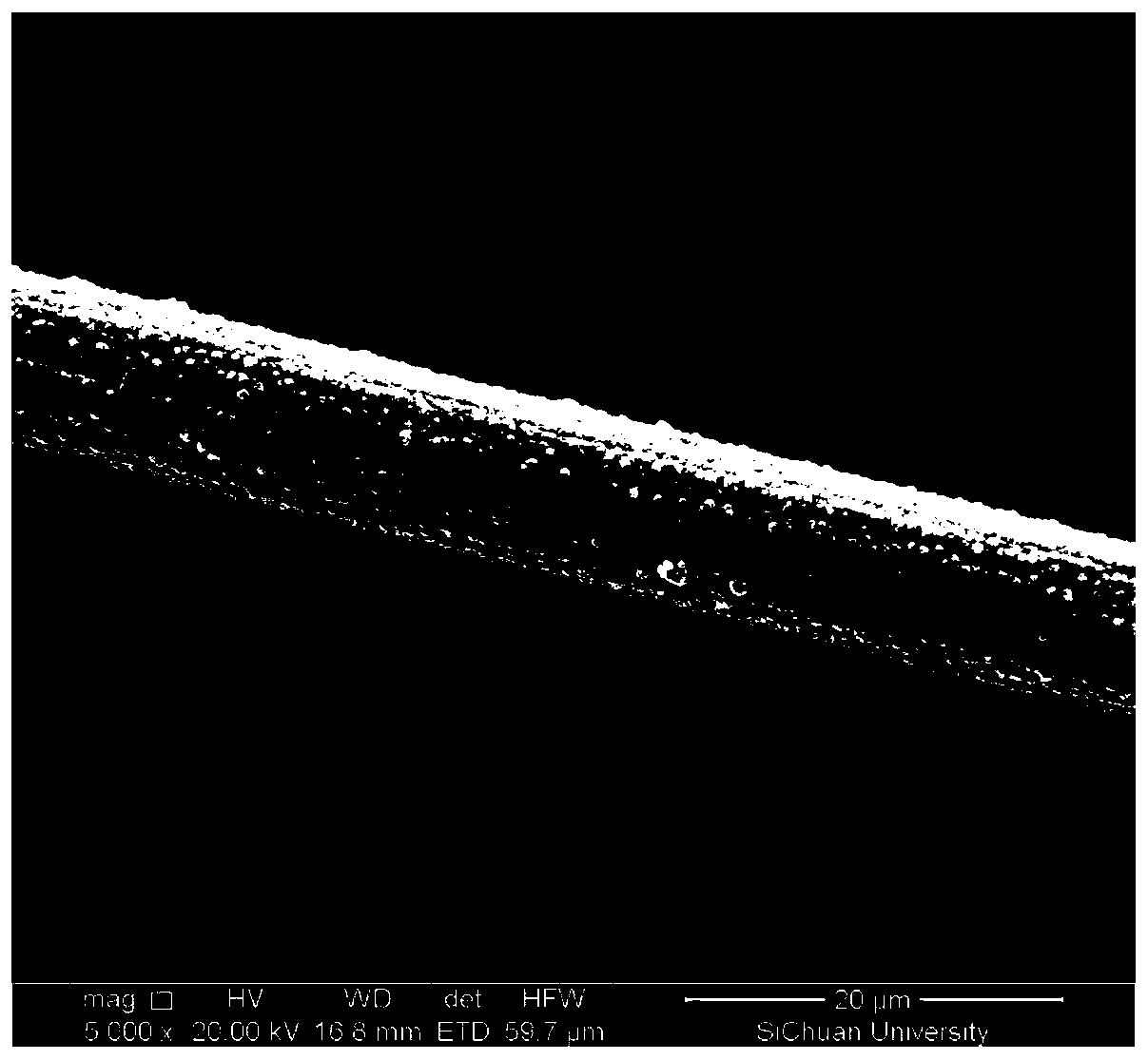

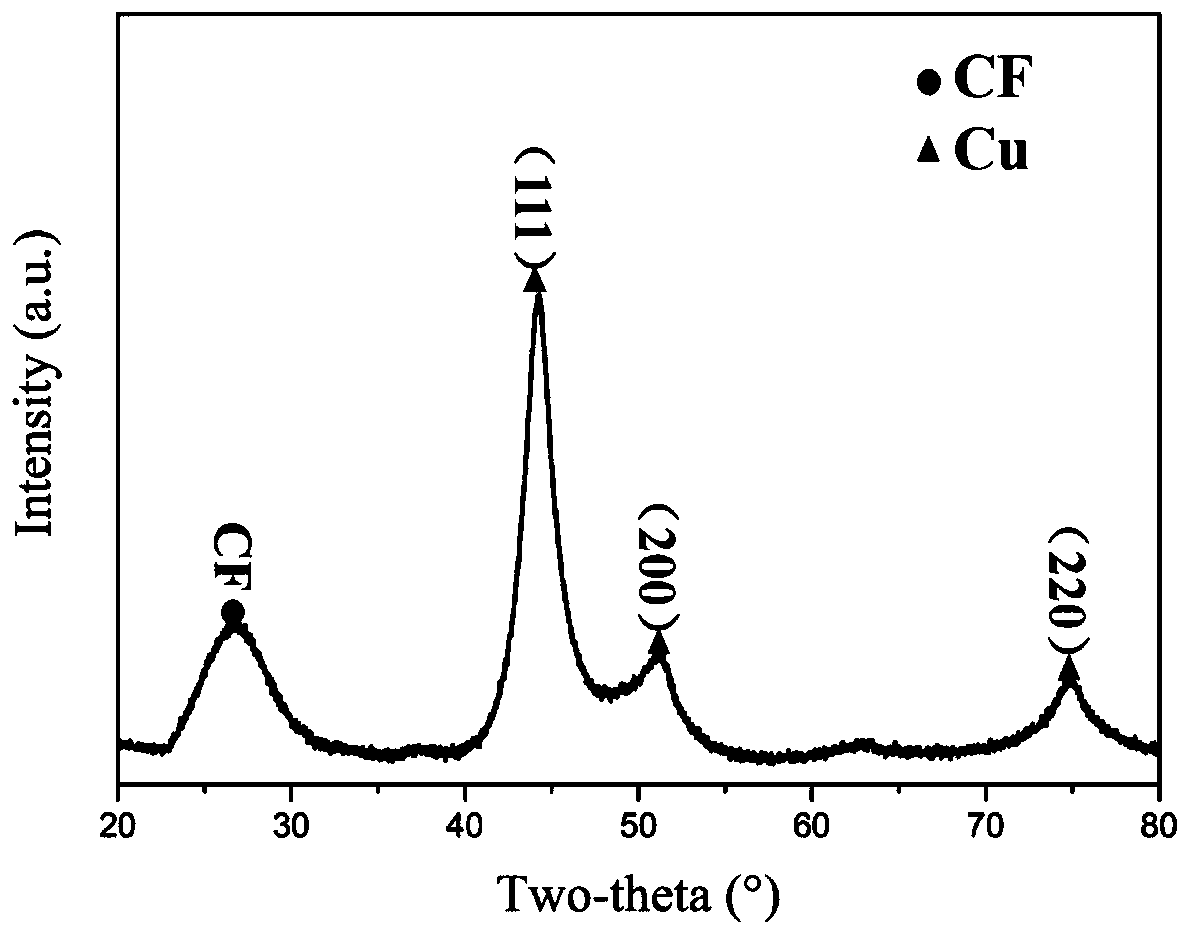

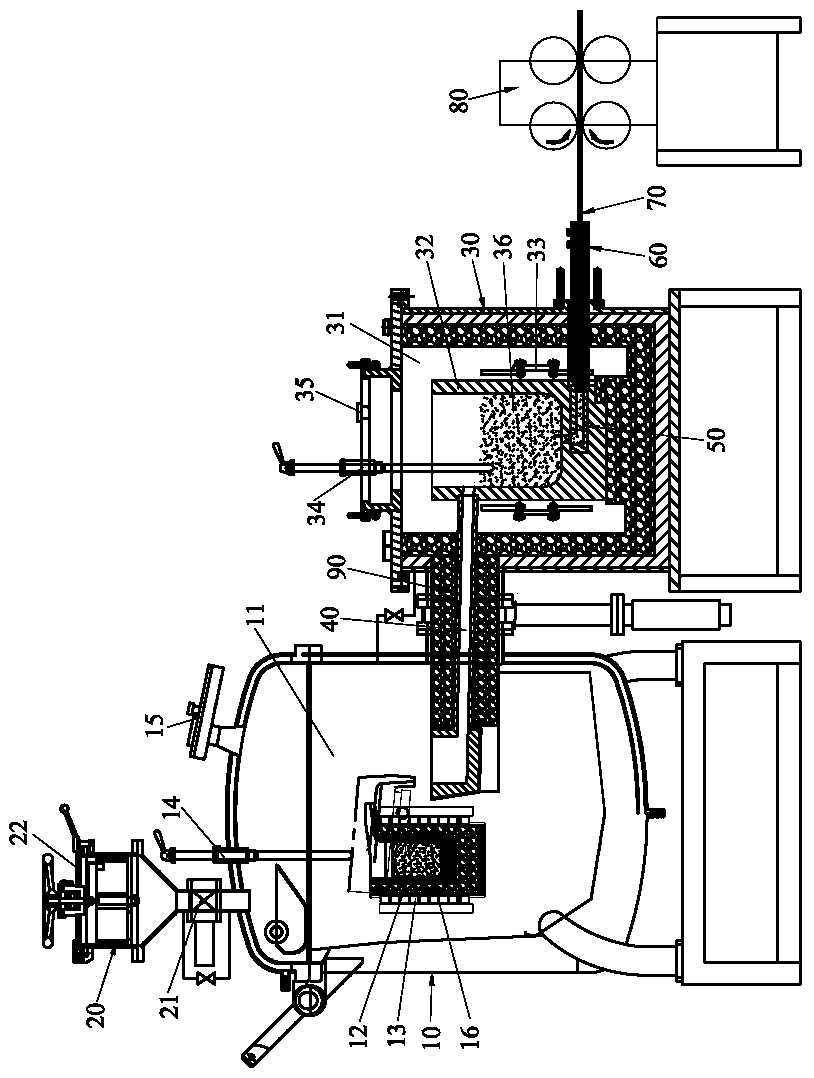

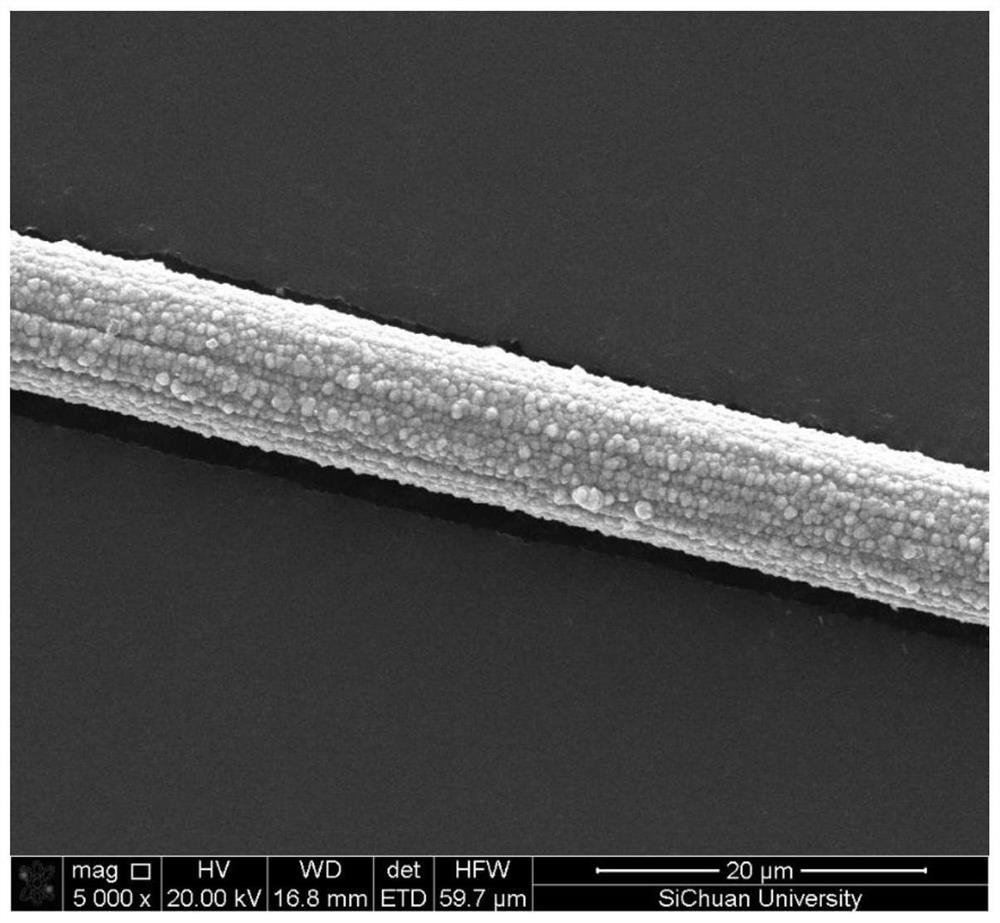

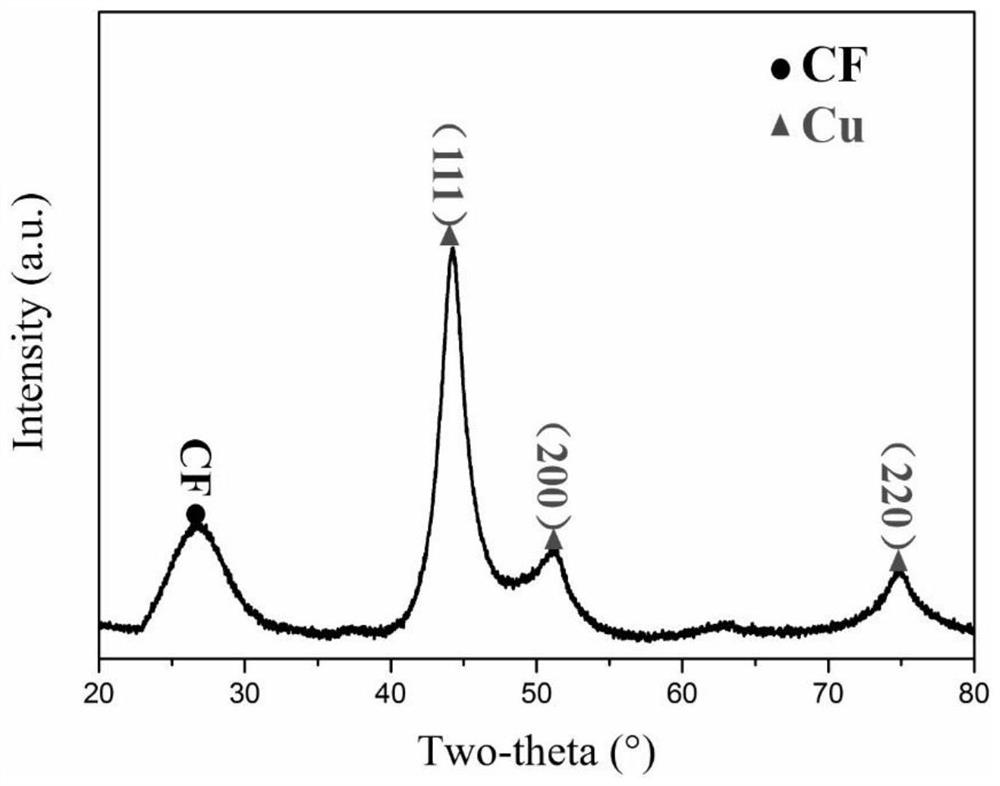

Preparation method of carbon fiber uniformly-electroplated copper layer

The invention discloses a preparation method of a carbon fiber uniformly-electroplated copper layer. The method comprises the steps: (1) desizing carbon fibers; (2) fixing the carbon fibers; and (3) taking the carbon fibers as a cathode and a phosphor copper plate as an anode, connecting a circuit, putting the connected circuit into an electroplating bath containing an electroplating liquid, adjusting the distance between the cathode and the anode to be 4-10 cm, keeping the current density to be 0.80-1.00 mA / cm<2>, the voltage to be 1.5-3.0 V and the electroplating temperature to be 10-30 DEGC, and electroplating for 60-90 min, wherein the electroplating liquid comprises CuSO4.5H2O, C4H4O6KNa.4H2O, C6H5Na3O7.2H2O, KNO3, polyethylene glycol, NaCl and water. According to the method, by controlling the components, the concentration and the current density of the electroplating liquid, the thickness, the uniformity and the surface appearance of the electroplated carbon fiber copper plating layer can be changed, the binding force of the plating layer is good and uniform, and the carbon fibers cannot be bonded.

Owner:SICHUAN UNIV

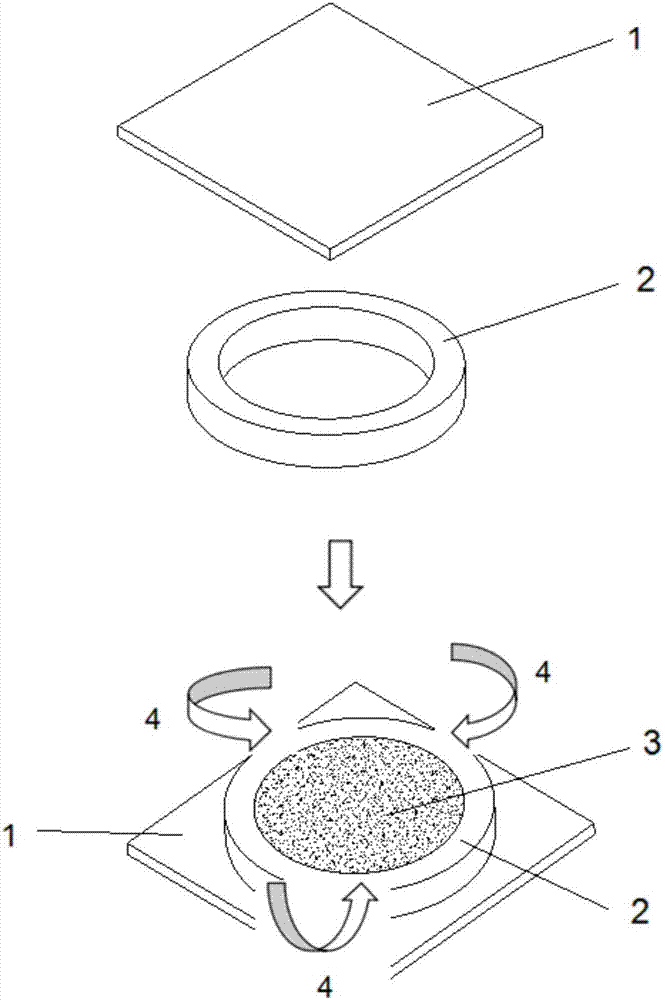

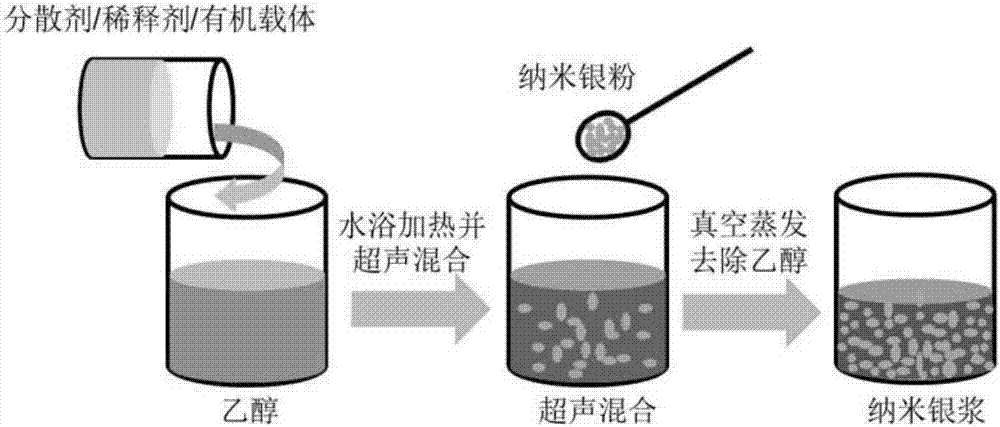

Preparation method of low-temperature sintering nanosilver paste heat conductivity testing sample

InactiveCN107271232AHigh mechanical strengthImprove thermal conductivityMaterial heat developmentPreparing sample for investigationOrganic solventSample integrity

The invention discloses a preparation method of a low-temperature sintering nanosilver paste heat conductivity testing sample. The preparation method comprises the following steps of preparing nanosilver paste; adhering a circular die onto a heat release adhesive tape, and filling the nanosilver paste into the whole die; drying an organic solvent in the nanosilver paste; pressing the nanosilver paste on a worktable, and continuing to fill the nanosilver paste until the nanosilver paste is fully filled into the whole die; pressing again until the nanosilver paste is fully filled into the die; removing the heat release adhesive tape, adhering the other surface of the die to a new heat release adhesive tape, and pressing until the nanosilver paste is fully filled into the die; removing the heat release adhesive tape, and sintering the semi-dry nanosilver paste at low temperature; grinding the sample, until the testing sample meeting the testing size requirement is formed. The preparation method has the advantages that the sample meeting the testing requirement is met; after the nanosilver paste is sintered, the structure is denser, and the mechanical strength and heat conduction property of the sample are improved; by using the heat release adhesive tape, the adhering with the nanosilver paste is avoided, and the sample integrity is better.

Owner:SHANGHAI UNIV

Rice processing method

Owner:扬州市金谷农副产品专业合作社

rice cake slicer

The invention proposes a rice cake slicing machine. The rice cake slicing machine comprises a cake slicing blade, a cake slicing blade driving device, a rice cake conveying belt, a rice cake slice receiving device and a rice cake slice receiving device lifting driving linkage piece, wherein the cake slicing blade is used for uniformly cutting strip-shaped rice cakes transferred along the rice cake conveying belt as rice cake slices; the rice slicing blade driving device is used for driving the cake slicing blade to perform the cutting and return reciprocating operations perpendicular to the strip-shaped rice cakes transferred along the rice cake conveying belt; and the rice cake slice receiving device is used for receiving the rice cake slices uniformly cut by the cake slicing blade on the rice cake conveying belt and conveying the rice cake slices for packing or storage. The rice cake slicing machine effectively solves such problems as time and labor wastes, nonuniform thickness and easiness in finger injury during cutting of rice cakes by kitchen knives, and can timely receive the rice cake slices through the rice cake slice receiving device for conveying to effectively prevent the integral bonding phenomenon caused by mutual extrusion of the adjacent rice cake slices.

Owner:辽宁走走进口食品贸易有限公司

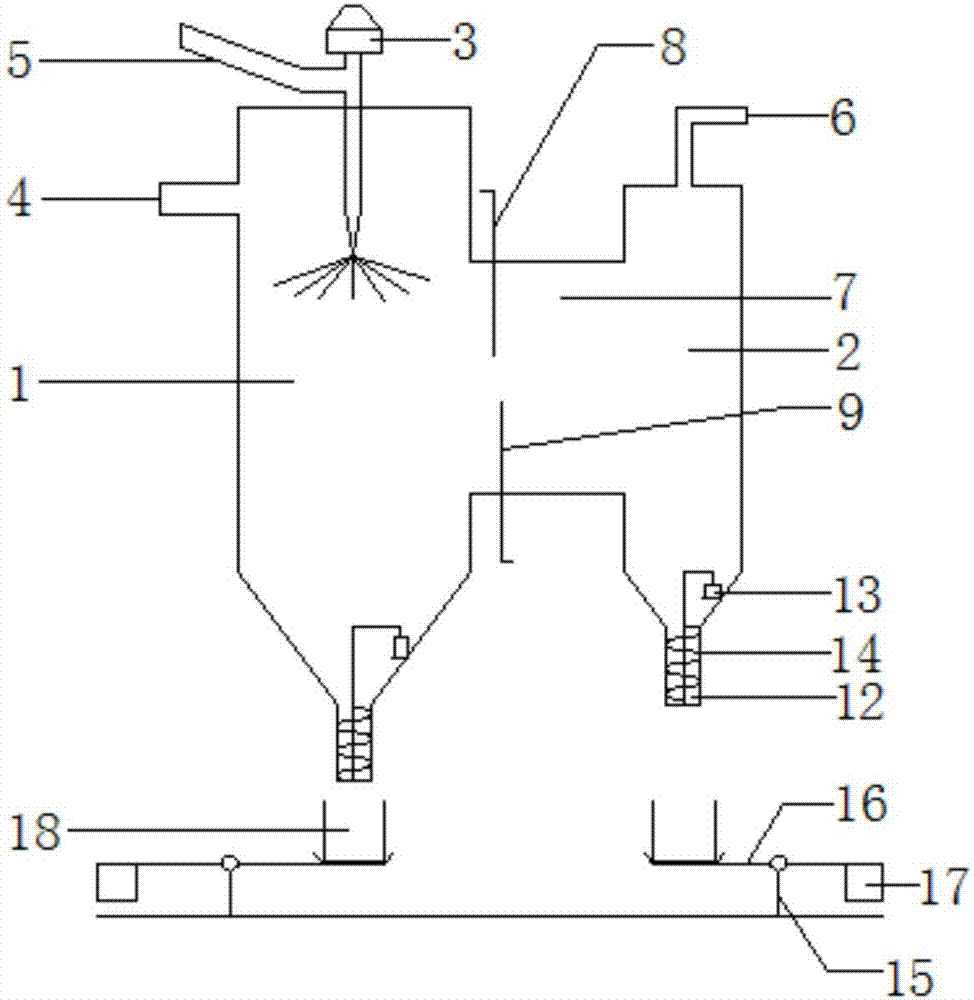

Spray dryer

InactiveCN107875659APlay the effect of quantitative dischargeAvoid weighing and packingEvaporator accessoriesEvaporator regulation/controlCycloneSpray nozzle

The invention discloses a spray dryer, which comprises a drying tower, a cyclone separator, and a high-speed centrifugal atomizer; the top of the drying tower is provided with a hot air inlet, and the high-speed centrifugal atomizer passes through the center of the top of the drying tower. The nozzle is located at the top of the drying tower, and the high-speed centrifugal atomizer is set concentrically with the drying tower. The high-speed centrifugal atomizer is provided with a feed port, and the top of the cyclone separator is provided with an air outlet; the side wall of the drying tower The side wall of the cyclone separator is provided with a chamber connected in the vertical direction, the chamber is provided with a first partition vertically inserted into the chamber from the top, and the chamber is provided with a vertically inserted chamber from the bottom. The second partition, by adjusting the position between the first partition and the second partition, the position of the air outlet on the drying tower and the size of the air outlet can be adjusted, so that the particle size of the material discharged from the chamber with the airflow can be adjusted. The size and the amount of material discharge can be flexibly controlled, and the invention is also provided with a weighing system.

Owner:CHENGDU YITIAN TECH CO LTD

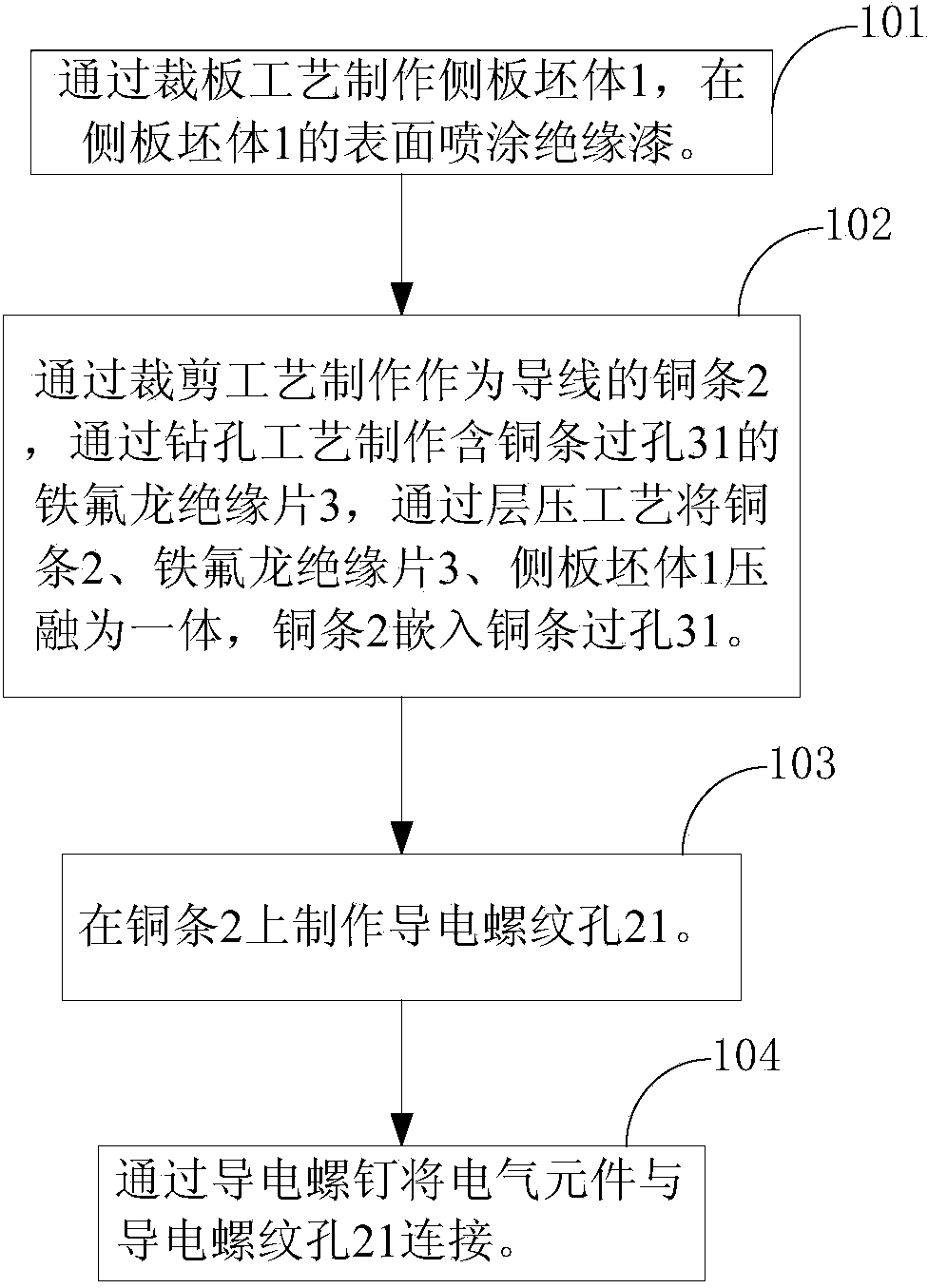

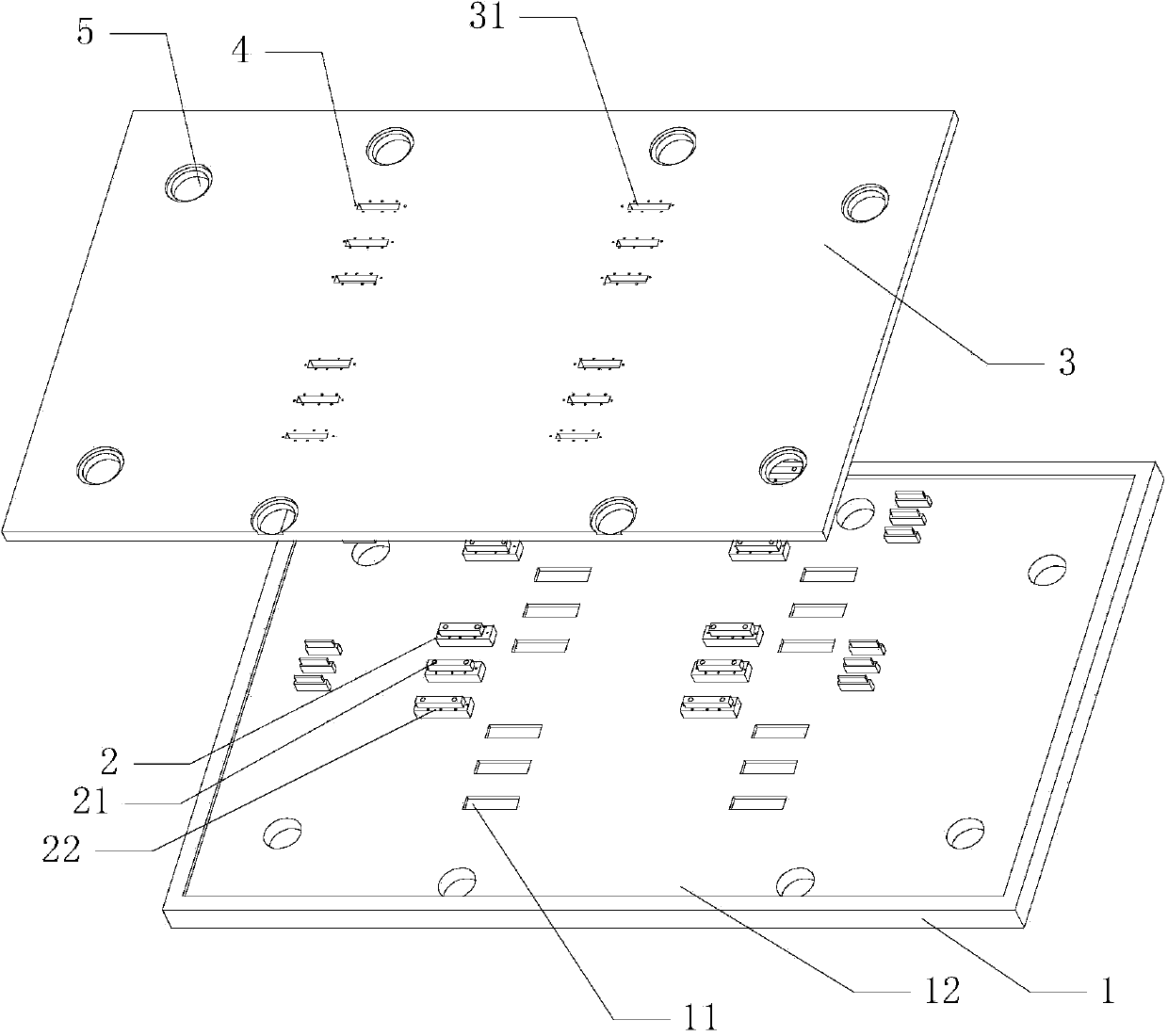

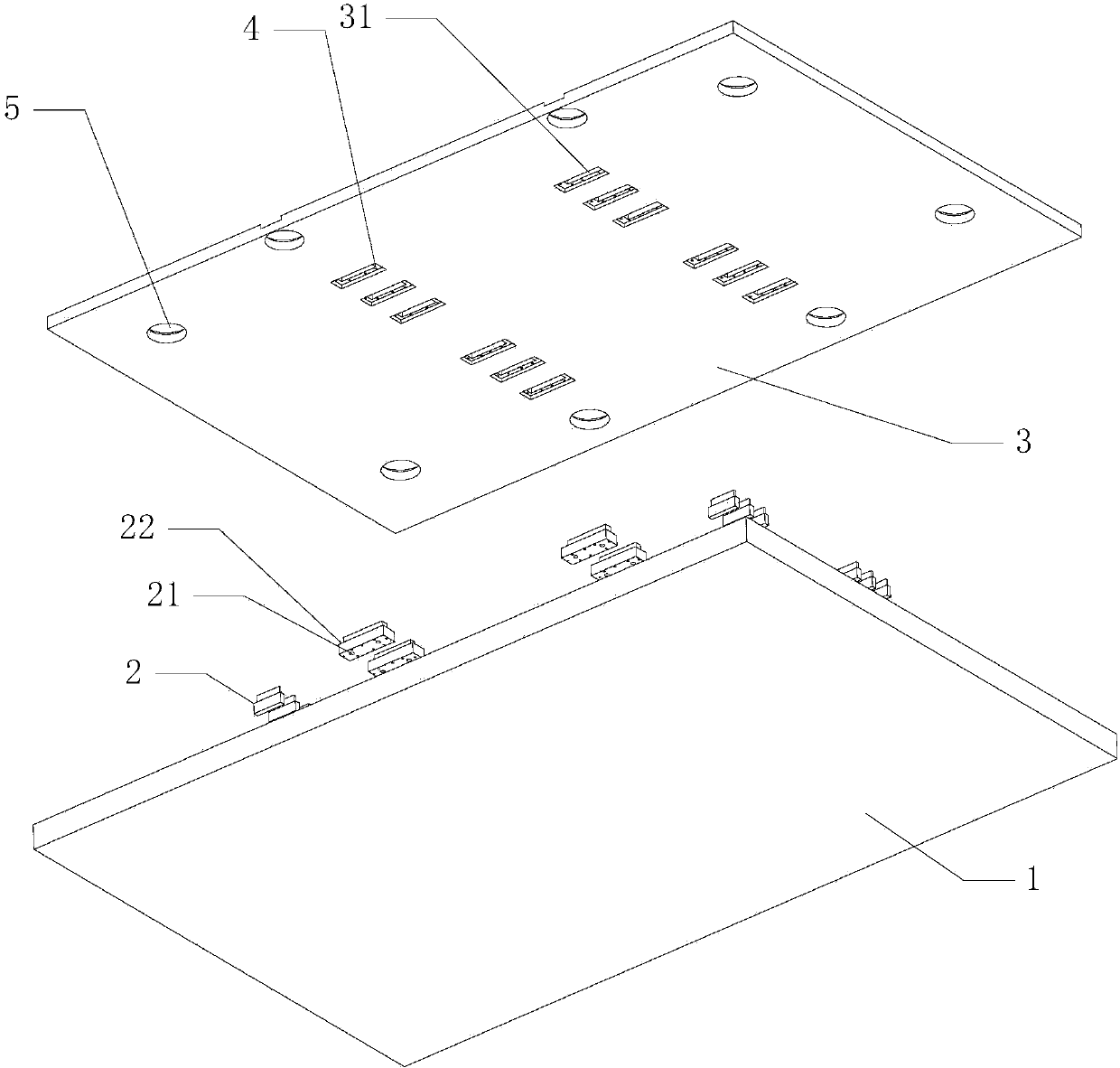

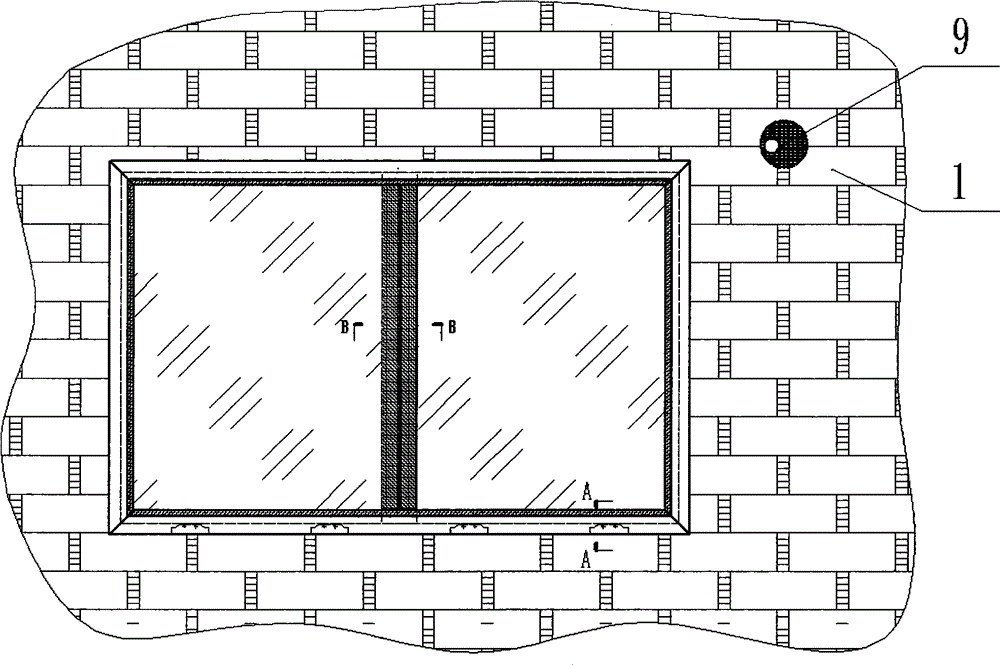

Manufacturing process for lateral plate of electric cabinet

ActiveCN103812040AThe connections are neat and orderlyReduce the probability of failureSwitchgearElectrically conductiveDrill hole

The invention discloses a manufacturing process for a lateral plate of an electric cabinet. The process includes that A. a lateral plate blank body is manufactured through a plate cutting process, and insulation paint is sprayed on the surface of the lateral plate blank body; B, a copper bar used as a lead is manufactured through a cutting process, a Teflon insulation plate with a copper bar via hole is manufactured through a drilling process, the copper bar, the Teflon insulation plate and the lateral plate blank body are fused integrally through a laminating process, and the copper bar is embedded into the copper bar via hole; C. conductive threaded holes are formed in the copper bar; D. electric components are connected with the conductive threaded holes through conductive screws. The electric components conduct electricity through the copper bar, the copper bar is embedded into the copper bar via hole of the Teflon insulation plate, connecting lines between the electric components are in order and can not be bonded with one another, and fault probability of the electric cabinet is effectively reduced.

Owner:轩金科技集团有限公司

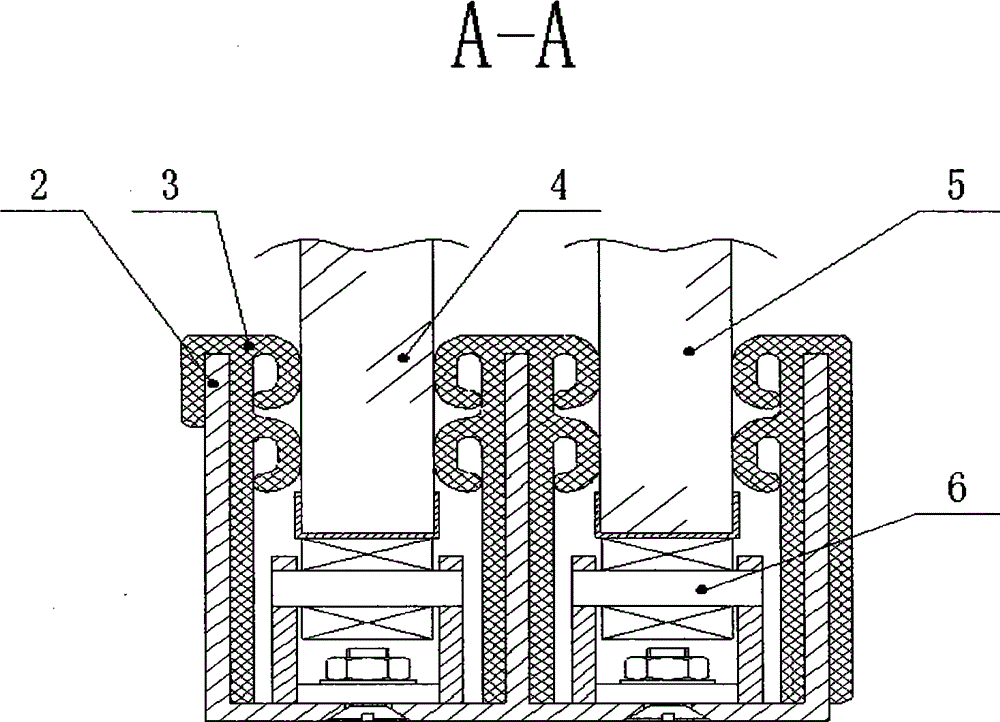

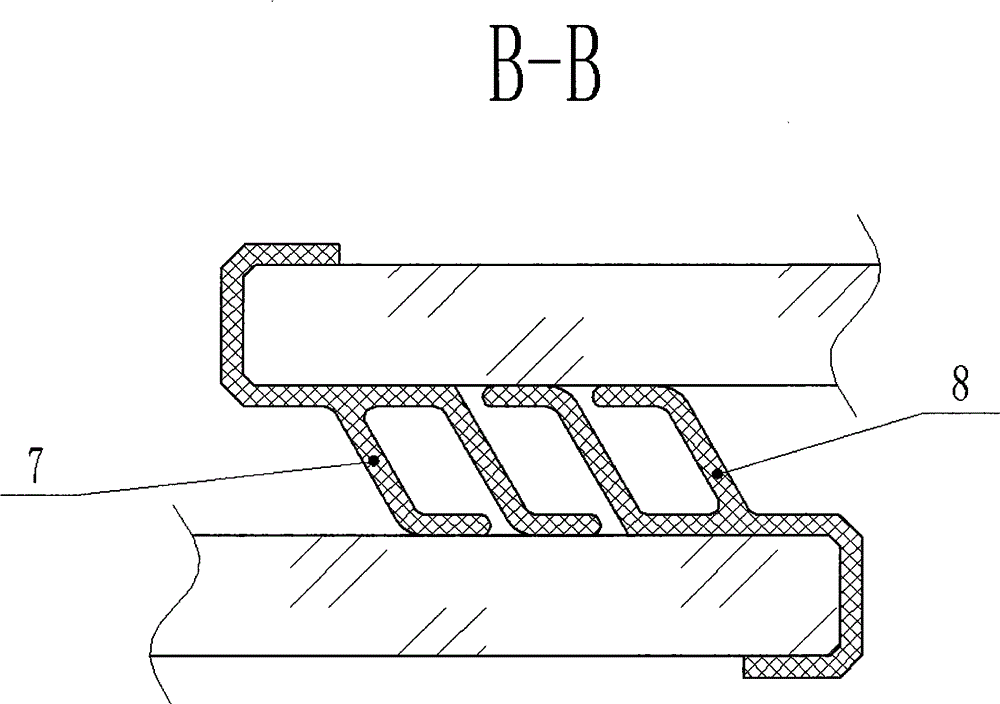

Novel sealing mode for soundproof window

InactiveCN104563818AEffective isolationEffective absorptionNoise insulation doors/windowsSealing arrangementsLip structureEngineering

The invention relates to a window, in particular to a novel sealing mode for a soundproof window. The window is composed of related accessories such as borders and sealing strips, wherein the borders are fixed on the periphery of a wall body of the window; the sealing strips are fixed on the borders. The novel sealing mode for the soundproof window has the characteristics that due to the sealing mode of the sealing strips, on one hand, the outer side surface of the contact part of each sealing strip and the corresponding border is large enough, and covers the border, so that noise can be effectively absorbed and isolated by the sealing strips when penetrating through the borders, and on the other hand, the contact part of each sealing strip and glass and the connected part between the glass and another glass adopt a lip structure design, so that the sealing strips can be effectively attached to the glass, thus preventing noise, dust, rainwater and the like from entering.

Owner:梁玉根

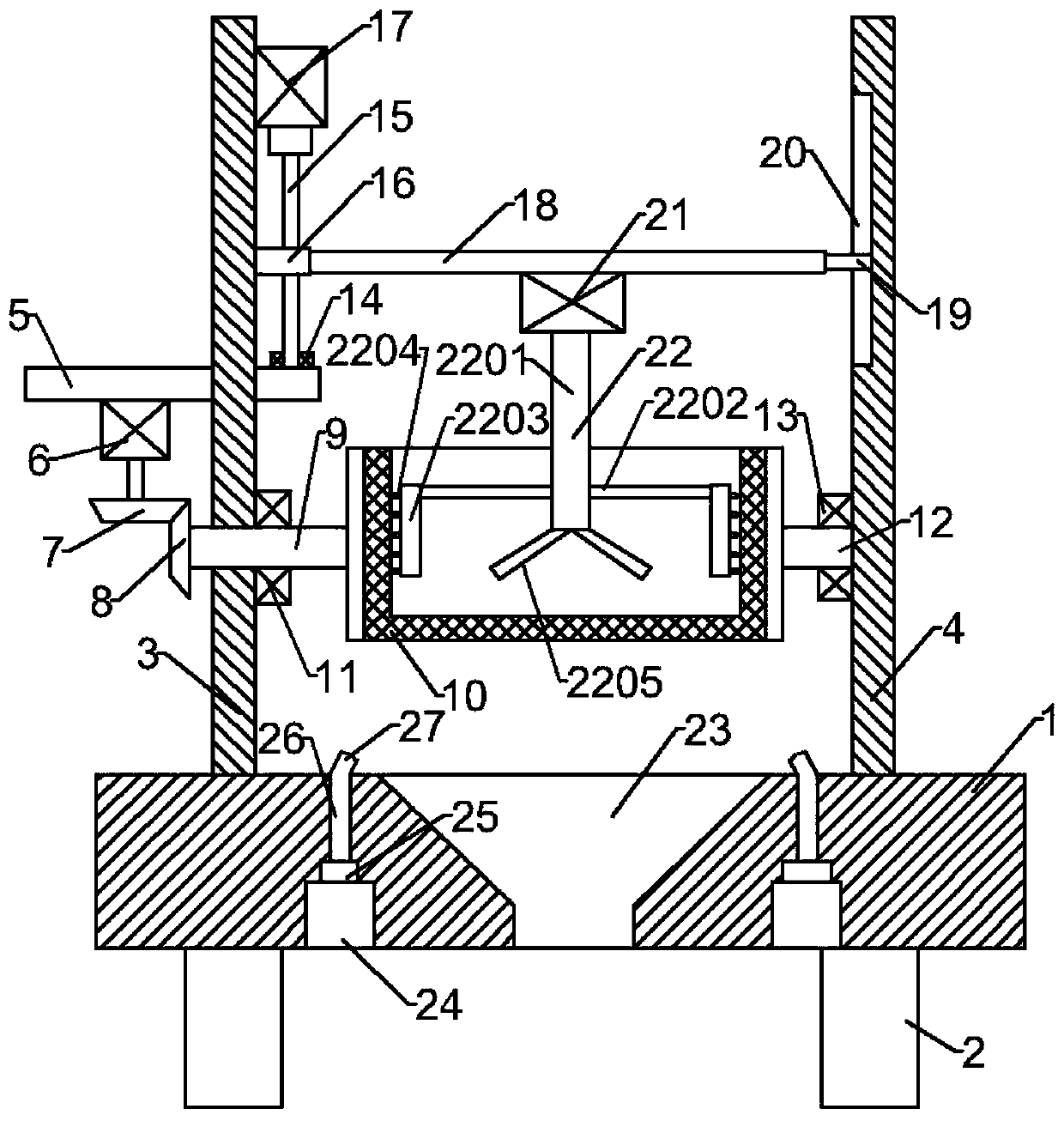

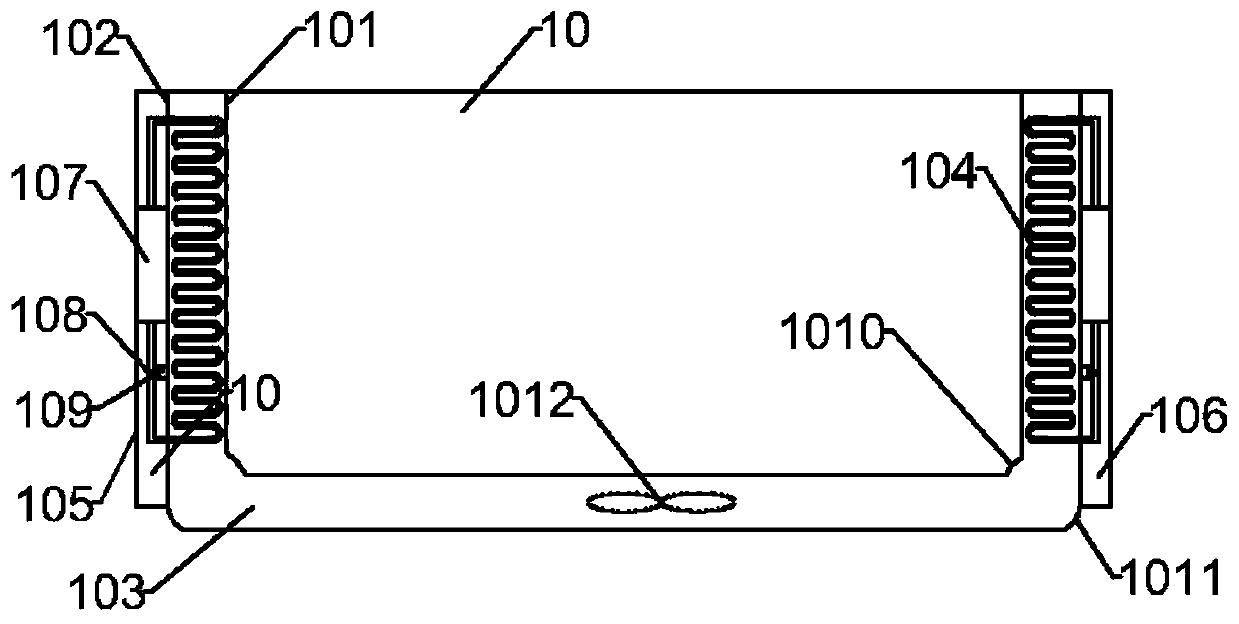

Building polyurethane waterproof paint stirring equipment

InactiveCN110292872AImprove stirring efficiencyWorking environment is cleanRotary stirring mixersTransportation and packagingWorking environmentEngineering

The invention relates to building polyurethane waterproof paint stirring equipment, which comprises a stirring platform, wherein support columns are symmetrically arranged at the lower part of the stirring platform; a first mounting frame and a second mounting frame are symmetrically arranged at the upper part of the stirring platform; a mounting plate is arranged at one side of the first mountingframe; and the mounting plate passes through the first mounting frame. In the process of mixing and dispersing a coating, the coating on the inner wall of a mixing box can be removed, and the coatingcan be removed while stirring, so that the stirring efficiency can be improved; meanwhile, the coating on the inner wall of box can be removed by water after stirring, so that a clean working environment can be realized, and the mixing box is convenient to continue to use next time.

Owner:肥西县碧涛建材有限公司

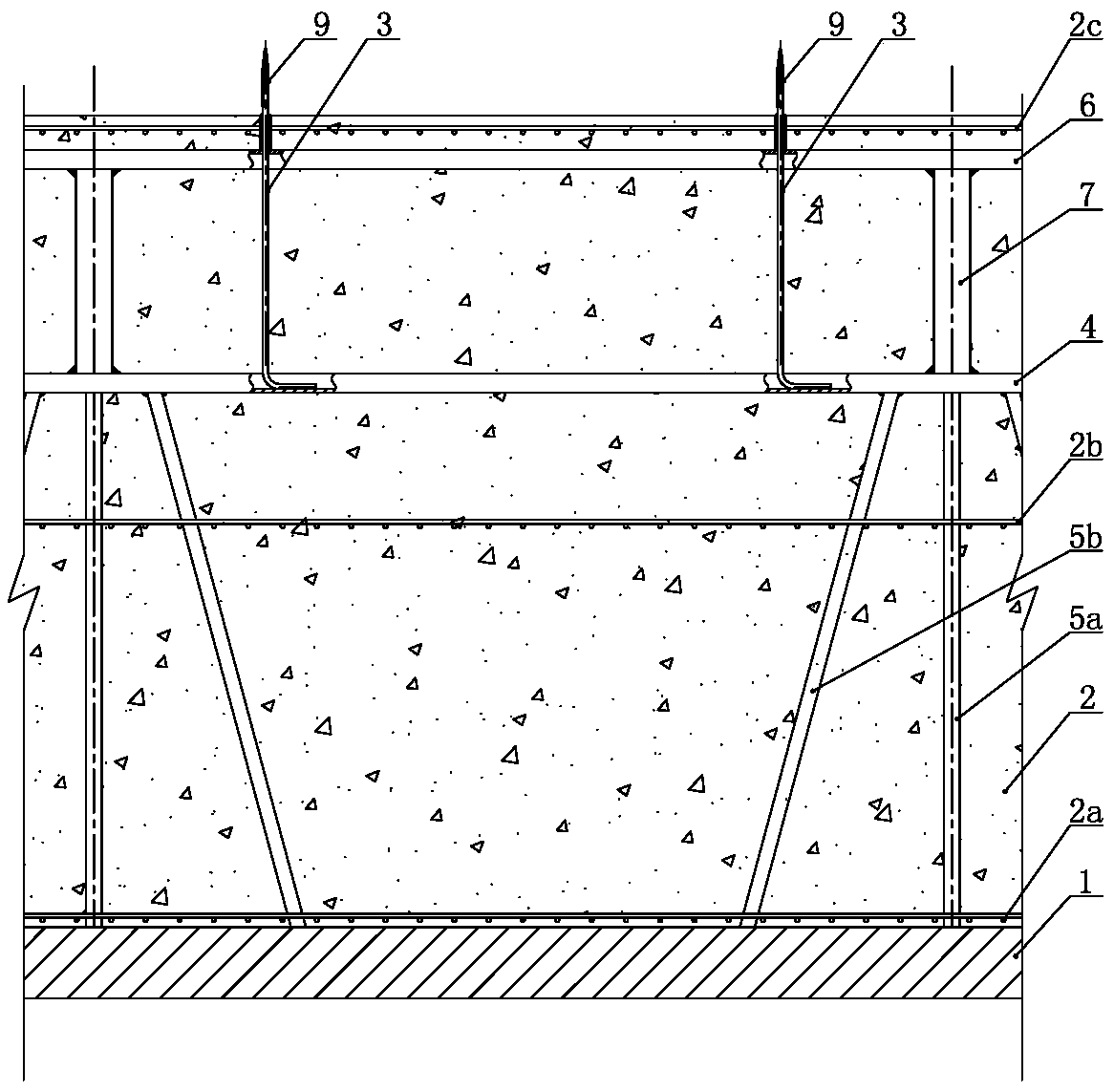

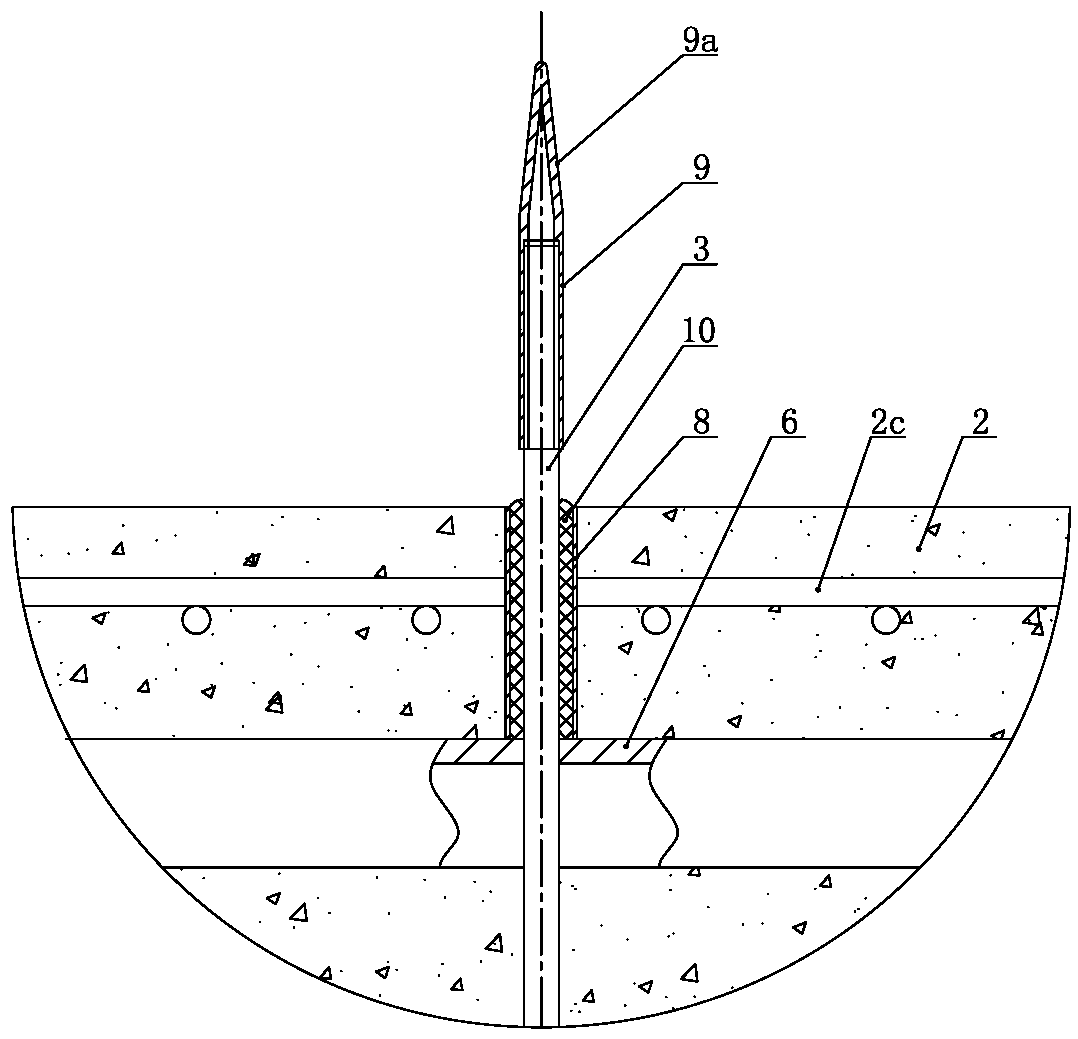

Foundation pre-burying device of large equipment and foundation installation method of large equipment

ActiveCN108677997AGuaranteed connection tensionStrong pullFoundation engineeringSpecial foundation layoutRebarCushion

The invention relates to a foundation pre-burying device of large equipment and a foundation installation method of the large equipment. The foundation installation method comprises the following steps that a bottom layer and middle-layer steel bars are bound to a plain concrete cushion layer, an anchoring frame is welded above the middle-layer steel bara, a positioning frame is welded above the anchoring frame, positions of foundation bolts are drawn on the top surface of the positioning frame, moreover, foundation bolt projection circles and outer sleeve projection circles are correspondingly drawn, positioning holes are cut out along the foundation bolt projection circles, the foundation bolts penetrate out of the positioning holes, and the lower ends of the foundation bolts are weldedto the anchoring frame; the outer sleeves are enabled to sleeve on the foundation bolts, and inner cavities of the outer sleeves are filled with flexible materials; and after top layer steel bars arebound, vertical molds are erected, then concrete pouring is carried out, base cushion iron is placed beside each of the foundation bolts after the concrete is solidified, after protective adhesive tape and the flexible materials are removed, the equipment is hoisted in place, equipment bolt holes are aligned with the foundation bolts to fall on the base cushion iron, and nuts are screwed on the foundation and then are tightened. According to the foundation pre-burying device of the large equipment and the foundation installation method of the large equipment, the positions of the plurality offoundation bolts can be accurate, the anchoring force is large, and one-time in-place success is achieved.

Owner:中石化石油工程技术服务有限公司 +1

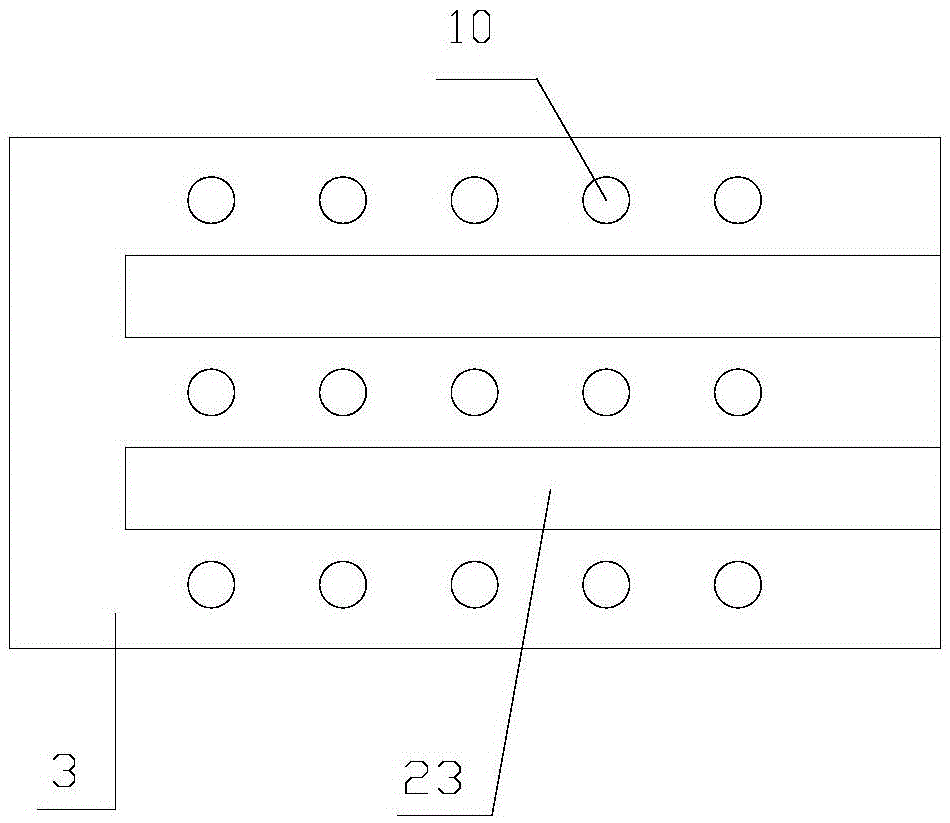

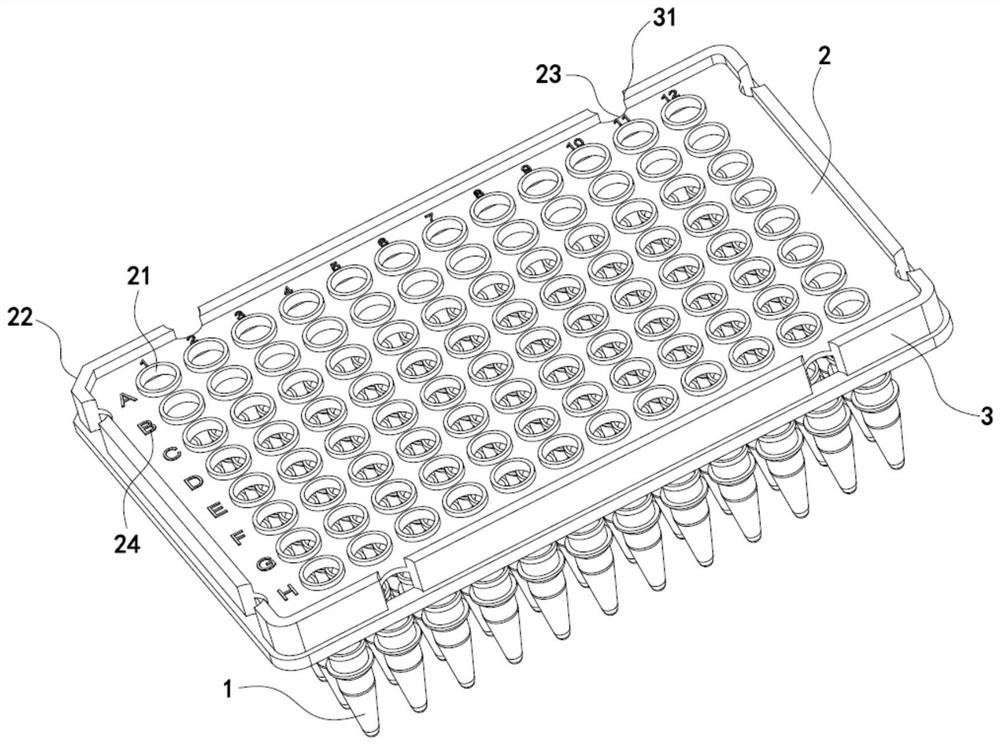

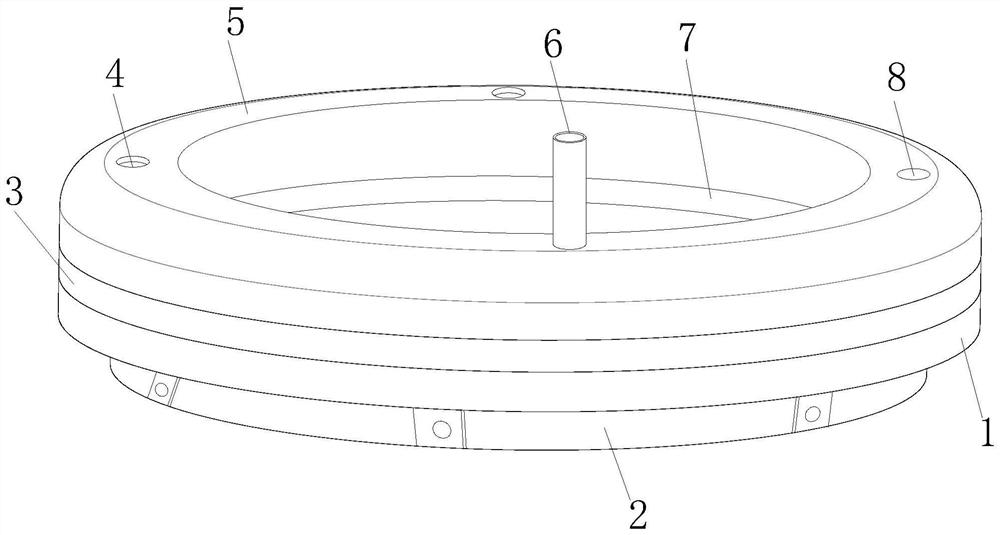

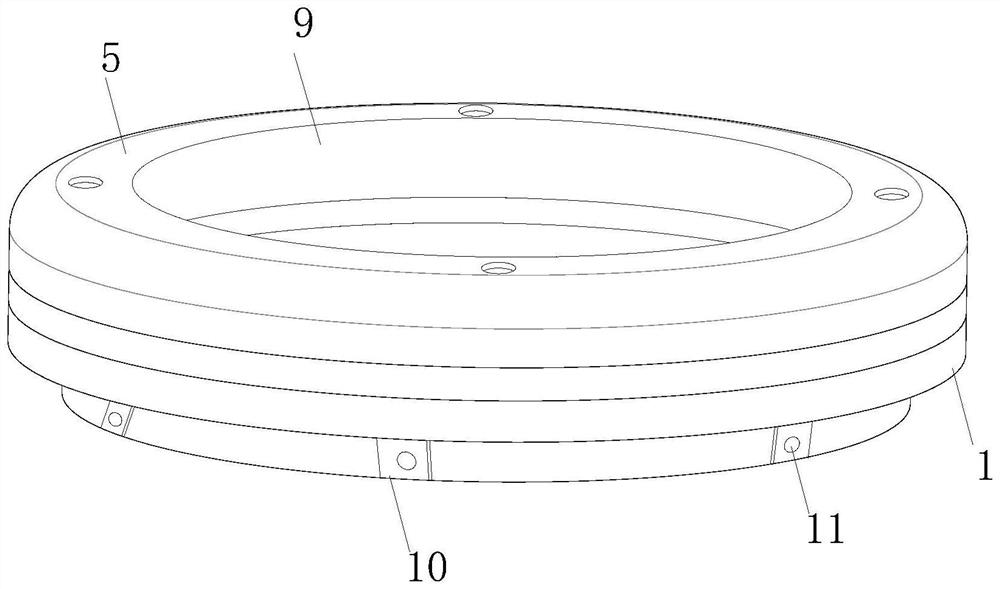

PCR plate

PendingCN113999753AImprove structural strengthAvoid deformationBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringManipulator

The present invention relates to the technical field of cell culture structures, and discloses a PCR plate, the PCR plate comprises a reaction tube and a panel made of a PC material, the reaction tube is arranged below the panel and is connected with the panel, and the panel is provided with a through hole corresponding to the reaction tube. According to the PCR plate, the panel is prevented from deforming due to temperature, the panel is not adhered to the PCR heating module, the working efficiency is improved, the panel does not deform when the PCR plate is clamped by the manipulator, and the PCR plate can be well adapted to an automatic system.

Owner:GUANGZHOU JET BIOFILTRATION CO LTD

Preparation method and preparation device of collagen peptide product easy to absorb

PendingCN114214381AFully contactedOptimizing the effect of alkaline cleaningBioreactor/fermenter combinationsConnective tissue peptidesProcess engineeringCollagenan

The invention provides a preparation method and a preparation device of an easy-to-absorb collagen peptide product, and relates to the field of health care product preparation.The preparation method comprises alkali treatment, heat treatment, enzymolysis treatment and drying treatment.The preparation device comprises a base, and an alkalization mechanism with an oscillation shaking-up structure is fixed to one side of the base; a heat treatment mechanism convenient for uncovering observation is arranged on one side, close to the alkalization mechanism, of the base. According to the device, the vibration assembly operates to enable the supporting plate to vibrate, the soaking and washing tank installed on the supporting plate through the limiting assembly can synchronously vibrate, alkali liquor in the soaking and washing tank flows under the action of external force of vibration and flows among fillet raw materials, and the contact area between the alkali liquor and the fillet raw materials is increased; moreover, the flowing state can ensure that the fillet raw materials are not bonded, the effective degree of alkali liquor washing can be greatly improved, and the alkali liquor is washed back and forth between the liquid injection interlayer and the tank body in the shaking process of the soaking and washing tank due to the special structure of the soaking and washing tank, so that the consumption of the alkali liquor is reduced compared with common washing.

Owner:上海美尔丽之生物科技有限公司

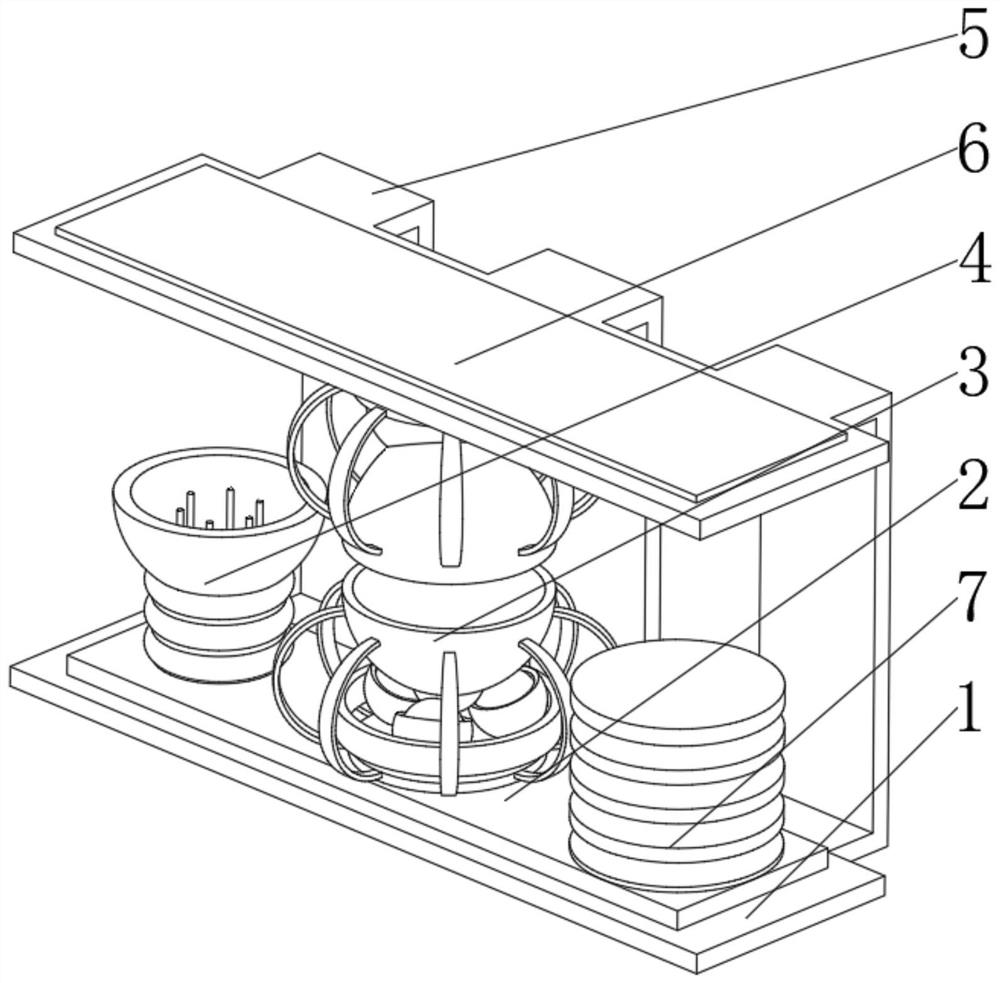

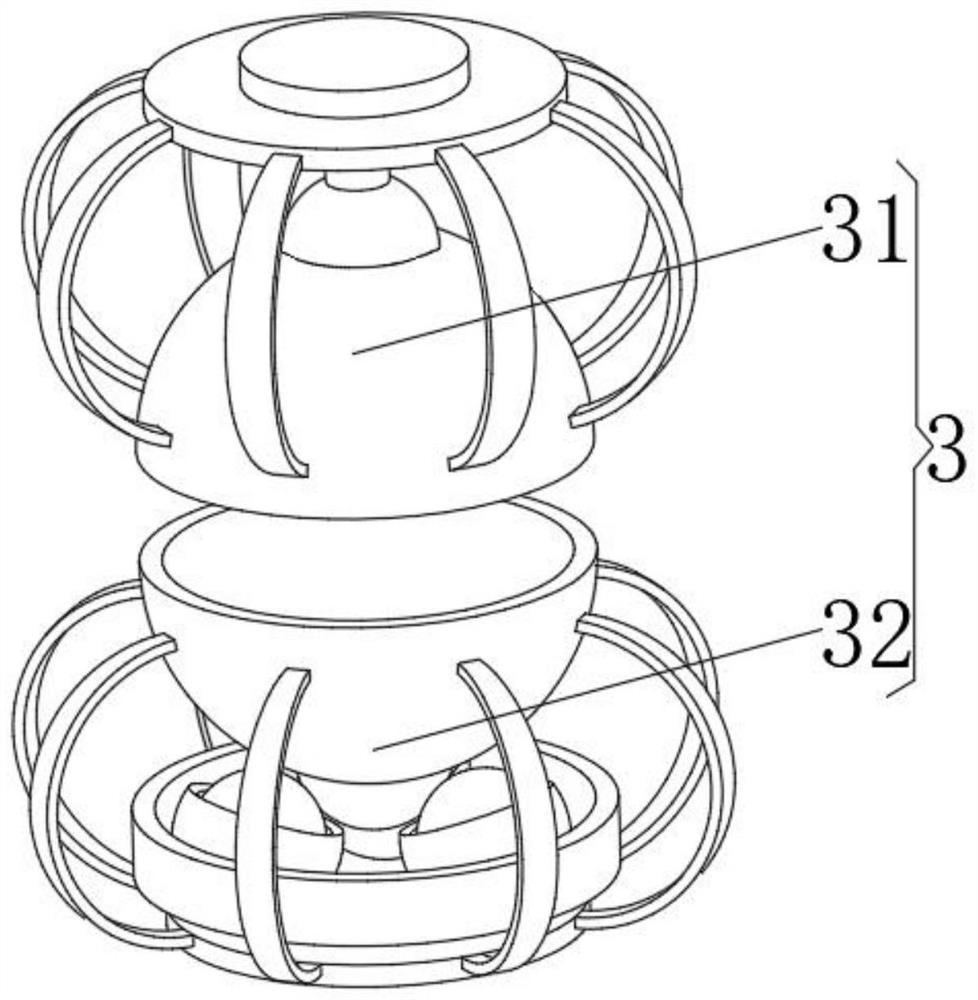

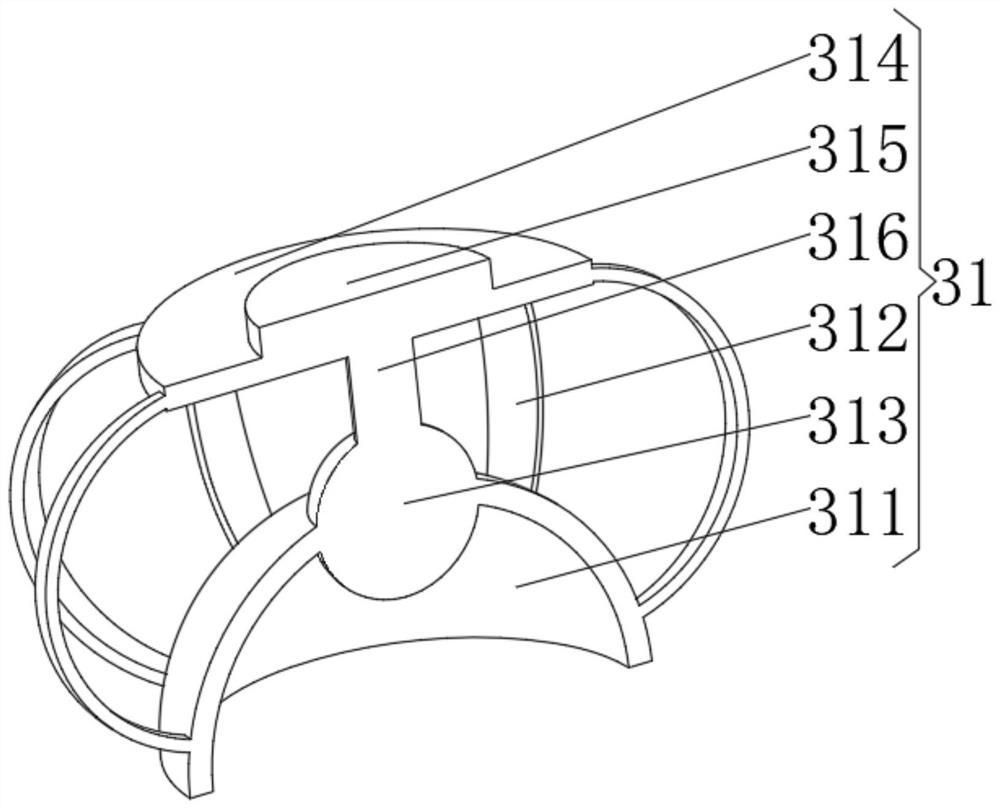

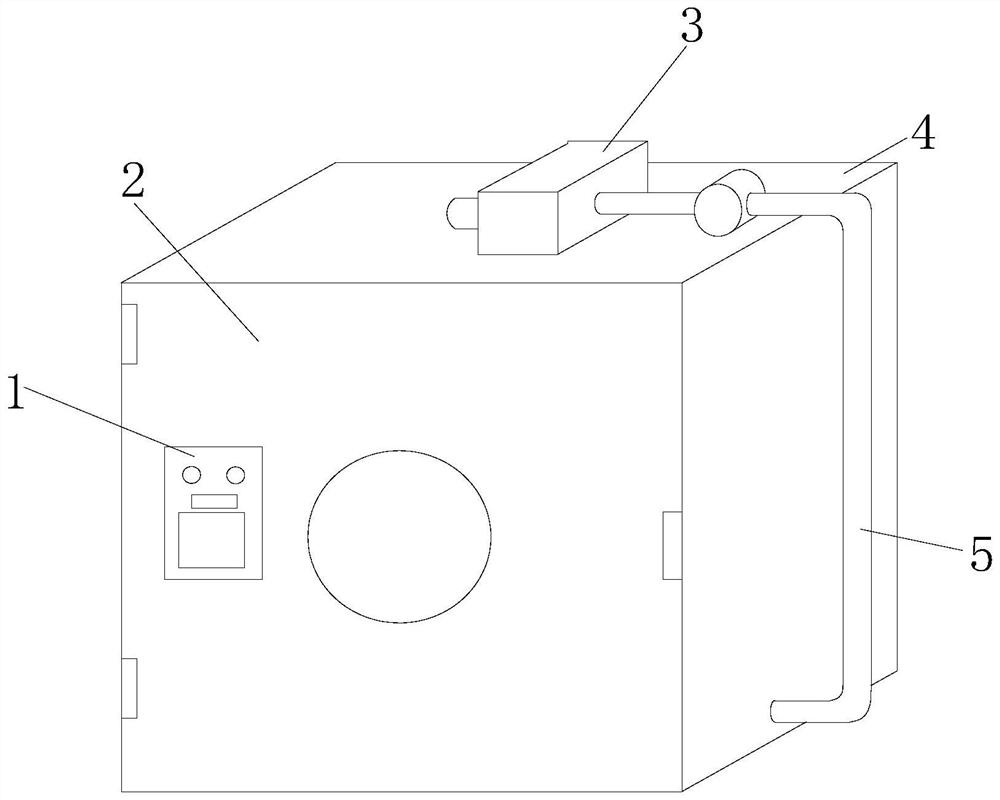

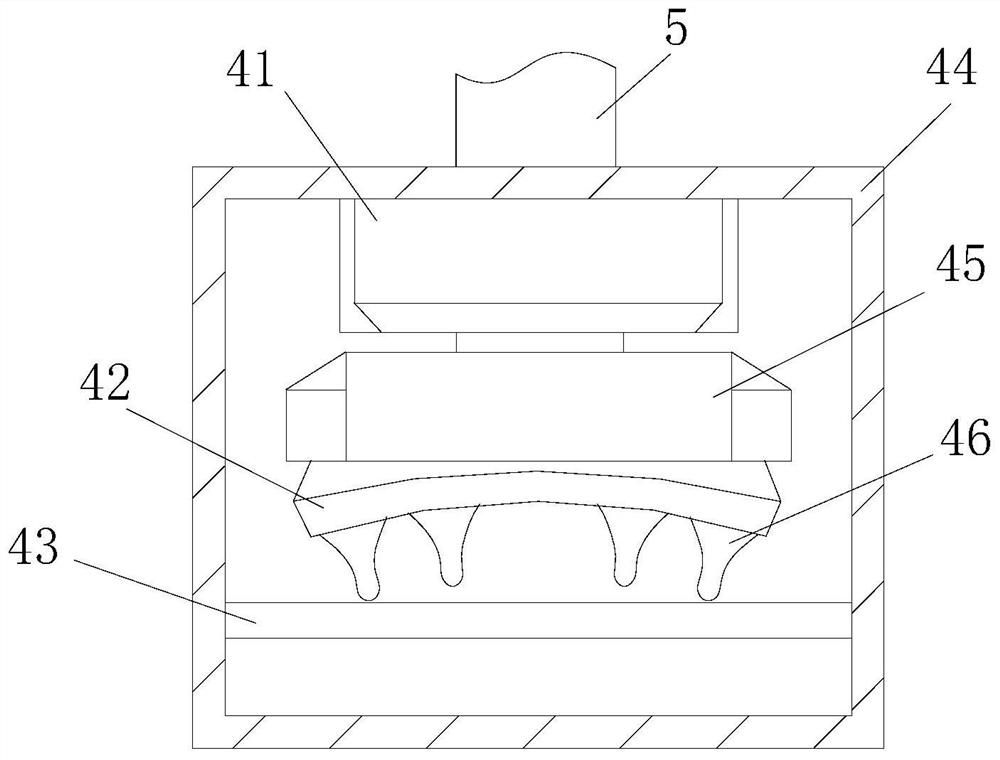

Intelligent casting island

The invention discloses an intelligent casting island which specifically comprises a supporting seat which is provided with a rectangular seat plate, a lifter mounted at the top of the rectangular seat plate, a die pressing mechanism mounted in the middle of the top of the lifter, a liquid injection mechanism mounted on the left side of the top of the lifter, a material receiving table installed on the right side of the top of the lifter and a driving track installed on the top of a supporting frame; the die pressing mechanism comprises a die fixing mechanism provided with a spherical main body and a die pressing applying mechanism provided with a columnar main body installed on the top of the lifter; the invention relates to the technical field of casting. And through the design of the rectangular seat plate of the supporting seat, the path length of the working procedure is prolonged, the movement time is prolonged in the movement process of an equipment mechanism, the temperature of the cast mechanism is conveniently reduced, thermal fatigue caused by continuous casting machining of the component is avoided, and the normal service life of the component is ensured.

Owner:范凤萍

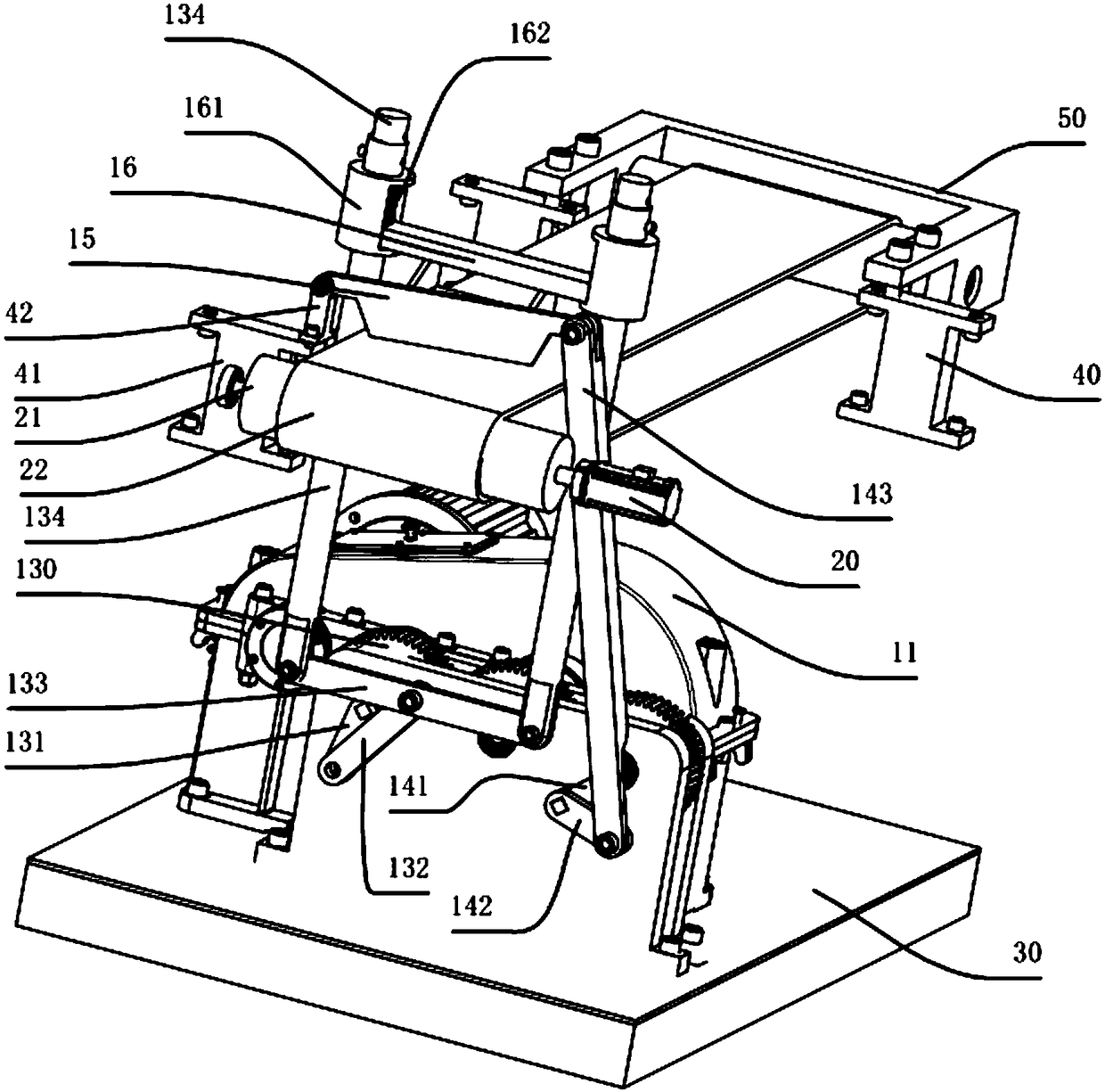

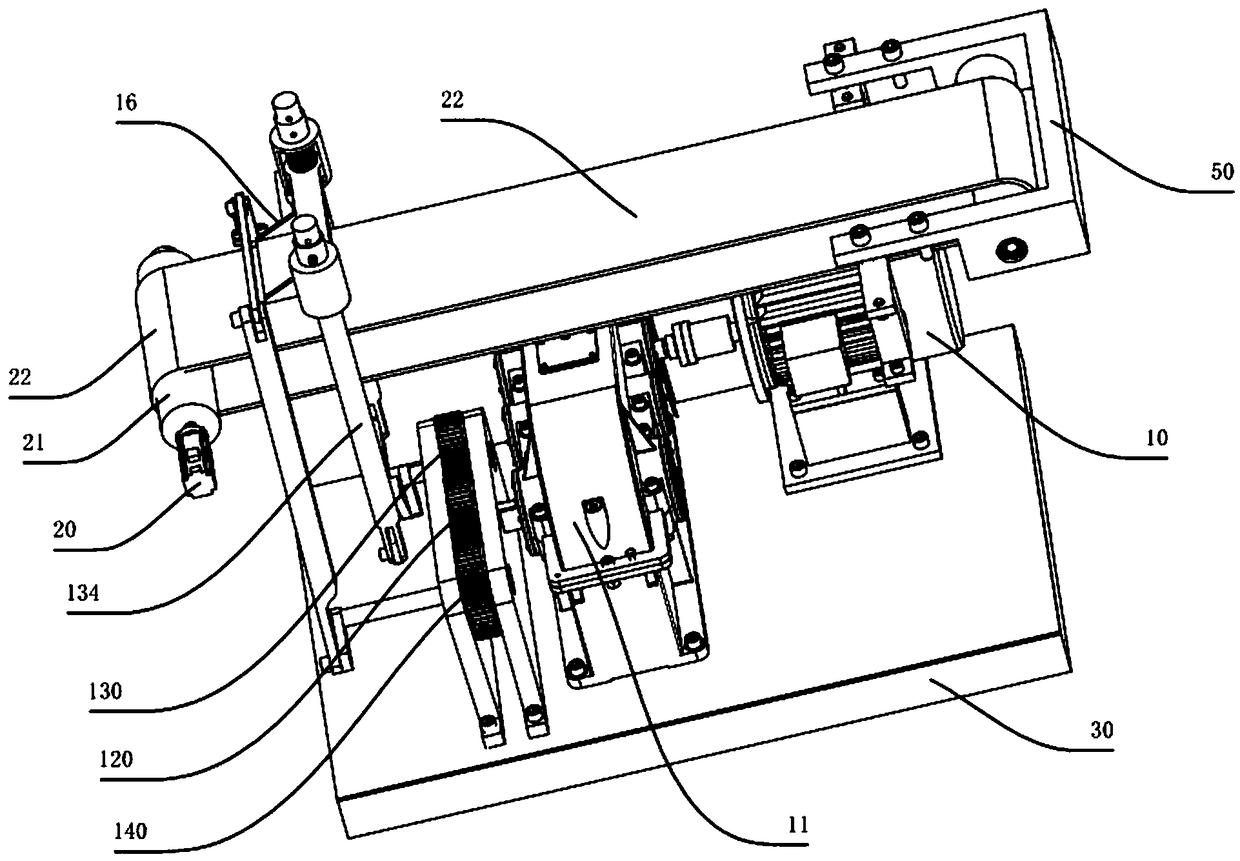

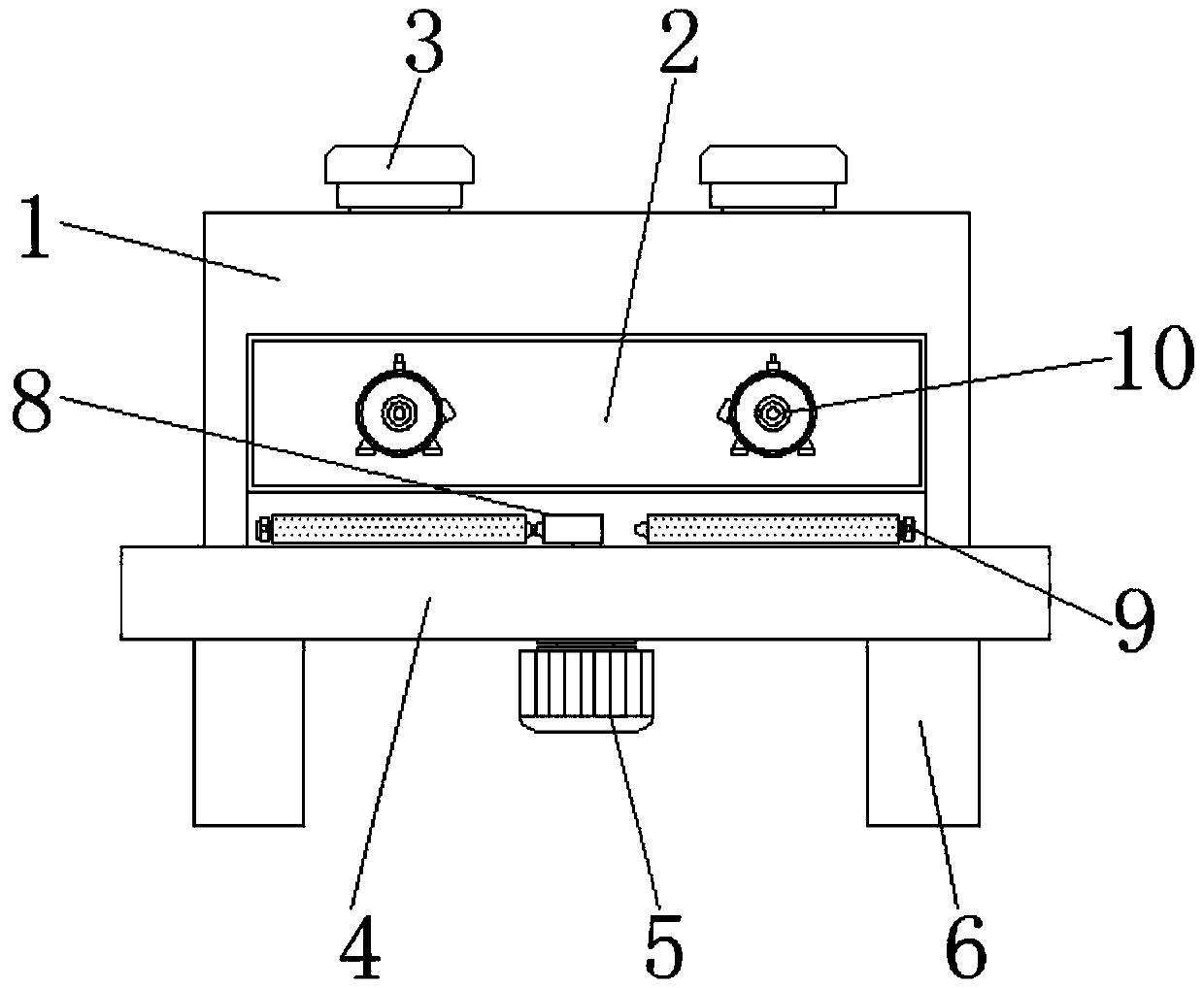

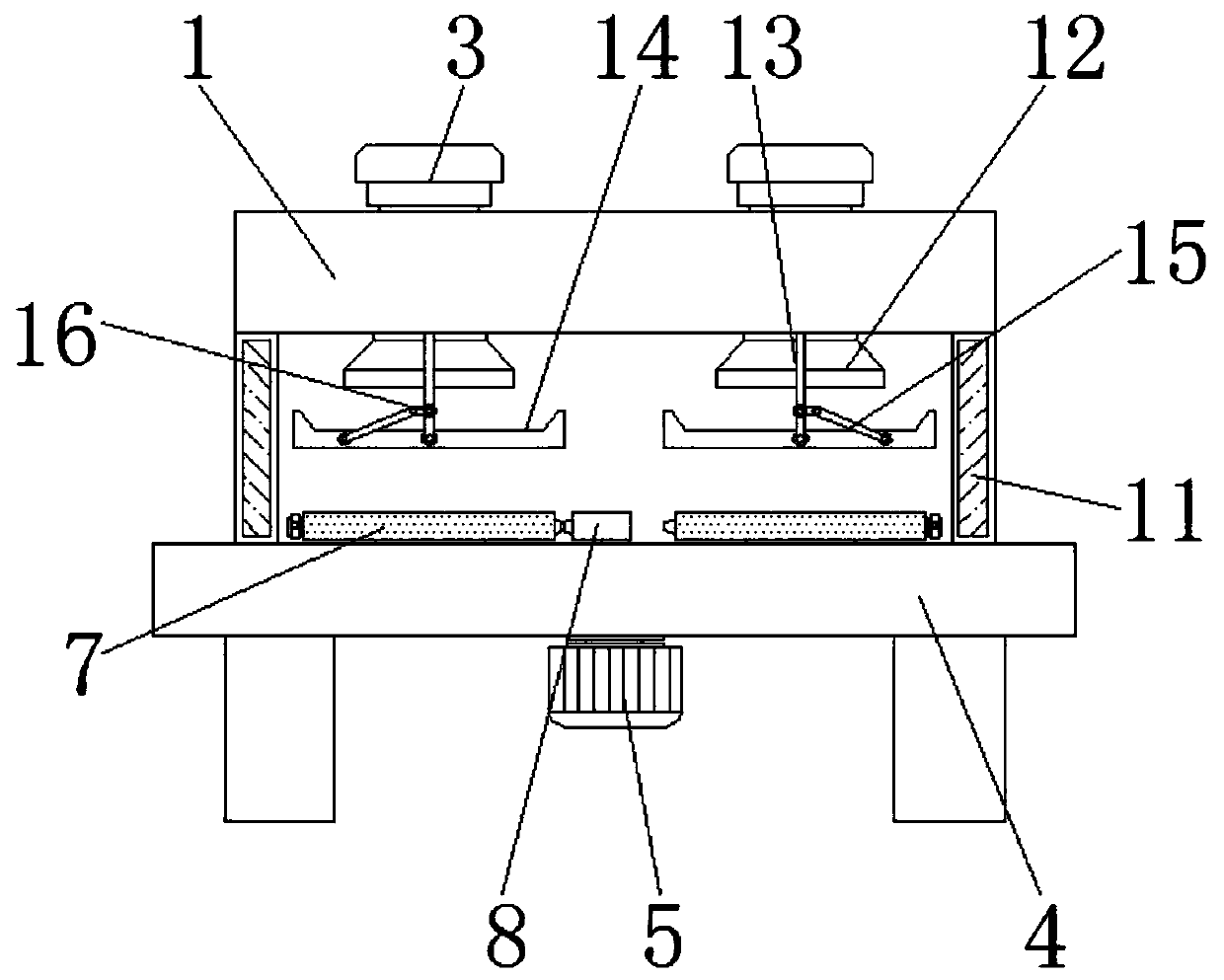

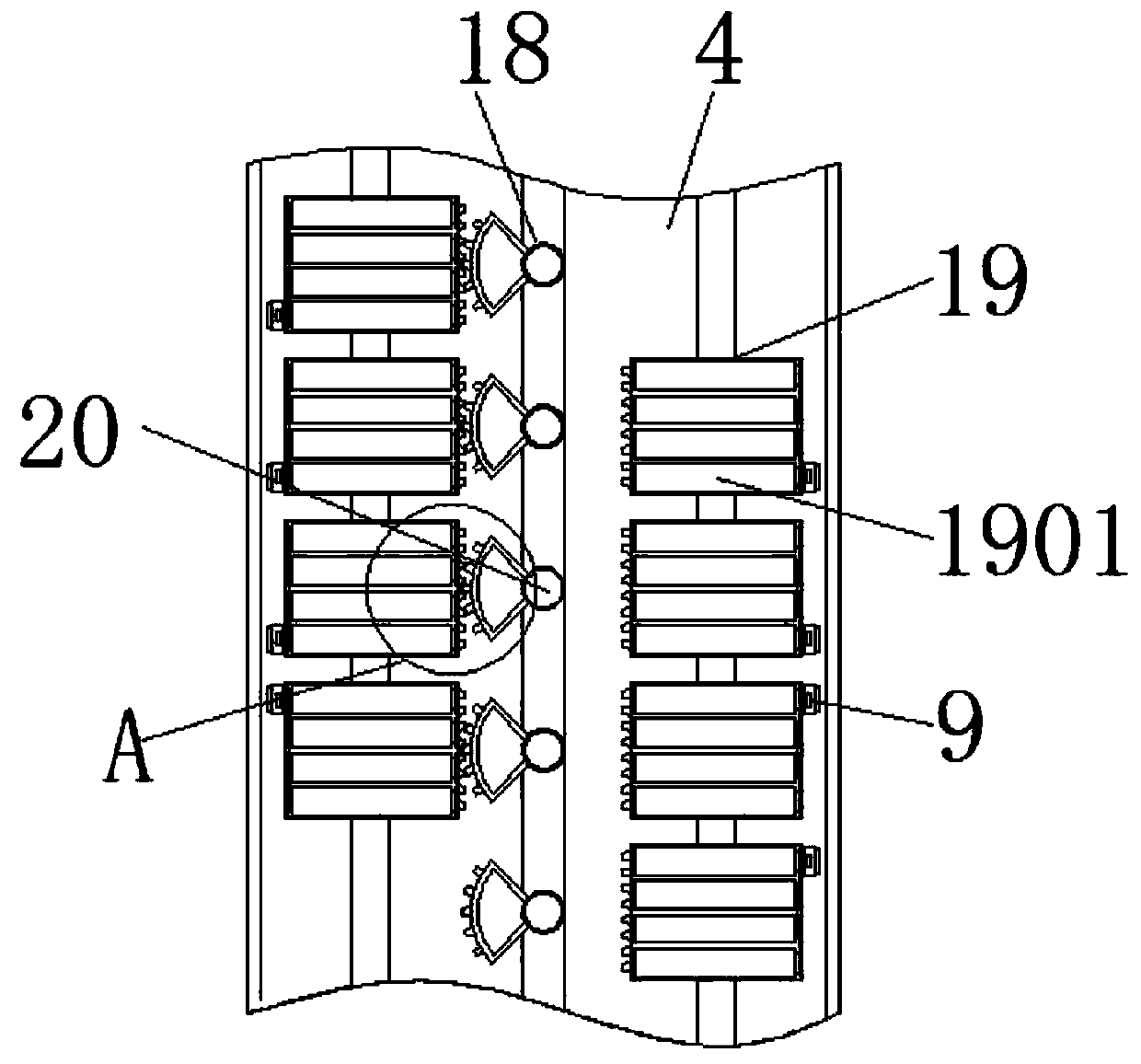

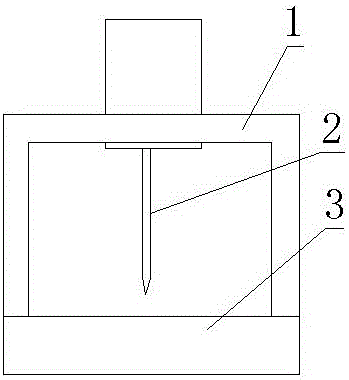

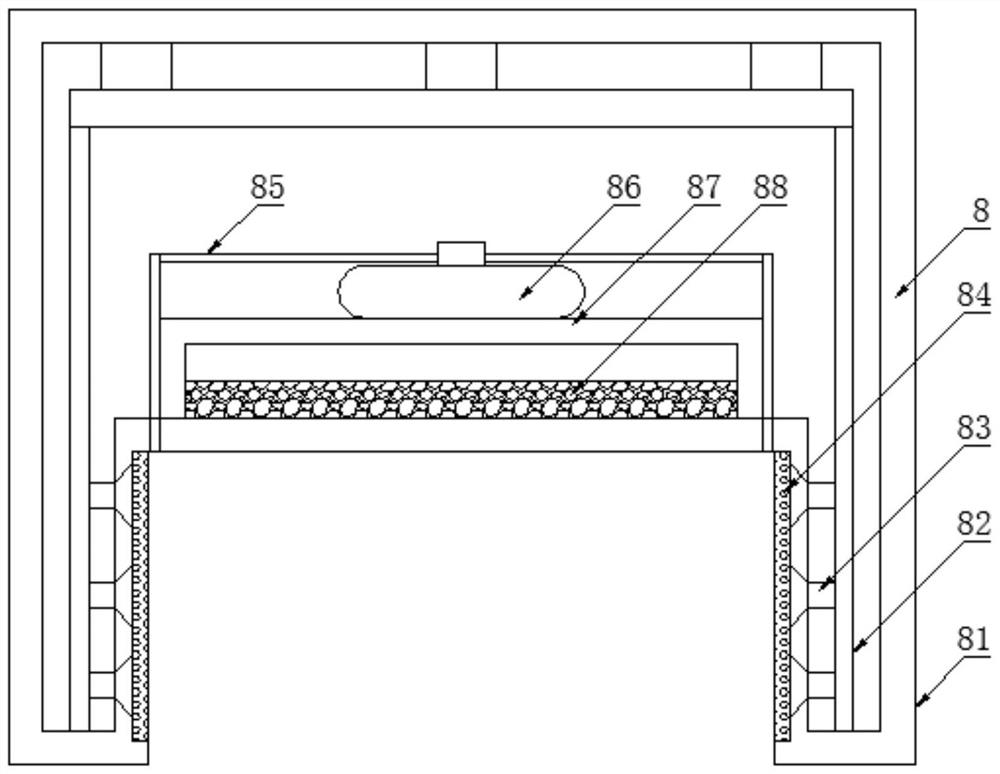

Water-washing pulp fluffing and drying equipment for sanitary towel production line

InactiveCN113293638AWill not bondPlay the role of pulling cottonPulp de-wateringPulp bleachingElectric machineryManufacturing line

The invention discloses a water-washing pulp fluffing and drying equipment for a sanitary towel production line. The water-washing pulp fluffing and drying equipment structurally comprises an operation board, a switch door, a motor, a machine box and a guide pipe; the operation board is connected to the switch door, the switch door is connected to one side of the machine box, and the motor and the guide pipe are mounted on the machine box; the water-washing pulp fluffing and drying equipment comprises a conveying rail, a crane, a drying table, a machine body, a connecting part and a push handle; the guide pipe is connected to the top of the machine body; the conveying rail and the drying table are connected to the interior of the machine body; and a connecting part is arranged on the conveying rail in a sliding fit mode, the push handle is mounted on the connecting part through the crane, and a pressing and twisting device and an auxiliary cutting structure are arranged on the push handle and matched with a cylinder through the pressing and twisting device and the auxiliary cutting structure. When the surface of a cotton ball is easily connected to the push handle in a filiform manner, the pressing and twisting device is firstly pressed in a through cavity, so that the pressing and twisting device is lifted to a specified position together with cotton silk on the surface of a twisted roll and is intermittently cut off by the opened auxiliary cutting structure, and it is guaranteed that the cotton cannot be bonded.

Owner:莆田市朝之辉电子商务有限公司

Plum candied fruit drying device convenient for spraying of sugar frosting

InactiveCN109548948AEasy to packThere will be no sticking of candied fruitConfectionerySweetmeatsGear wheelAgricultural engineering

The invention discloses a plum candied fruit drying device convenient for spraying of sugar frosting. The plum candied fruit drying device comprises a machine frame, a first motor, an electric motor,second motors, heating wires, fixing rods and rotating gears, wherein storage bins are mounted on the machine frame; the bottom of each storage bin penetrates through the middle position of the machine frame to be connected with a corresponding discharging opening; the lower part of the machine frame is connected with an operation table; each rotating gear is arranged outside the lower part of each second rotating shaft in a sleeving manner, and is arranged in a sliding groove in the machine frame; a placing device is arranged on the upper surface of the operation table; and one side of the placing device is connected with the electric motor. When the plum candied fruit drying device convenient for spraying of sugar frostin, is used, two-way operations of feeding and discharging can be well performed, and the situation that the whole device can be performed in a high-efficiency manner is guaranteed; and in the using process, the operation of spraying of sugar frosting on candied fruitscan be performed at the same time, so that the candied fruits are convenient to directly pack.

Owner:邓兴明

Fruit cutting machine

InactiveCN105690464AWill not bondNo delay in normal workMetal working apparatusAgricultural engineering

The invention relates to equipment in the technical field of fruit processing. The name is a fruit cutting machine, which includes a frame and a cutting knife. There is a chopping board under the cutting knife. There are a plurality of through holes running through both sides on the knife, and the cutting knife surfaces on the left and right sides of the through holes have grooves and raised structures arranged at intervals, so that the fruit cutting machine with such a structure can ensure that the fruit after cutting The advantages of not sticking to the surface of the cutter and not delaying the normal operation in the next step: the cutter surface on the left and right sides of the through hole has a structure of grooves and protrusions arranged at intervals, which can achieve the above-mentioned more Good results.

Owner:CHANGGE QUANXIN ENG MACHINERY MFG

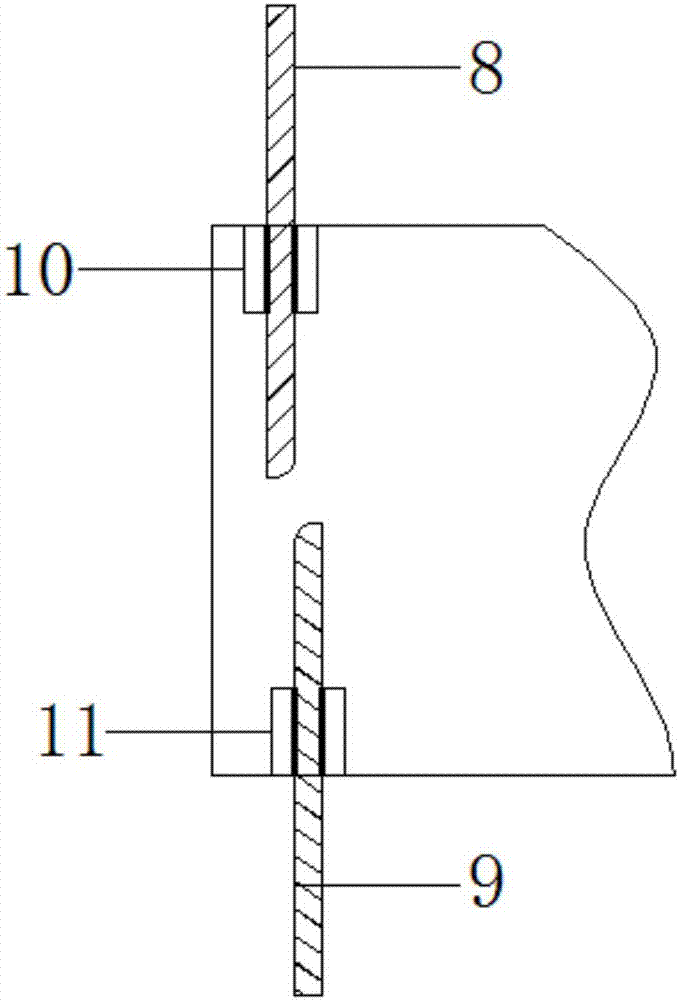

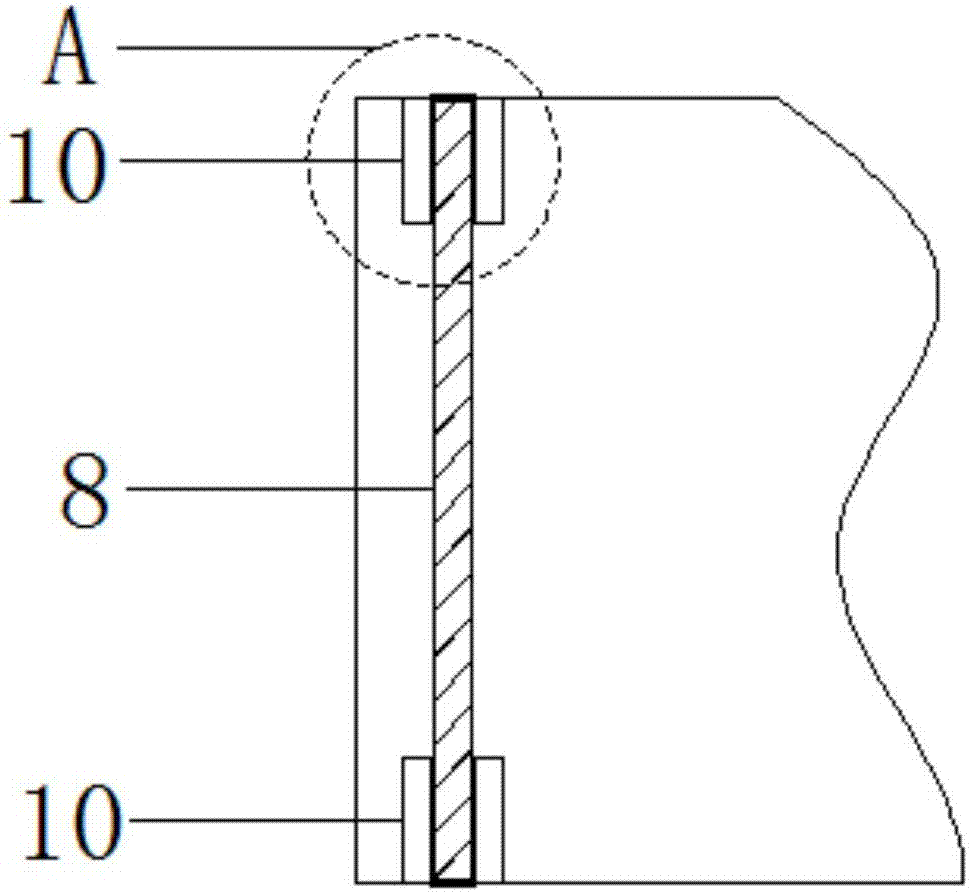

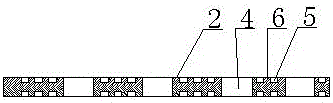

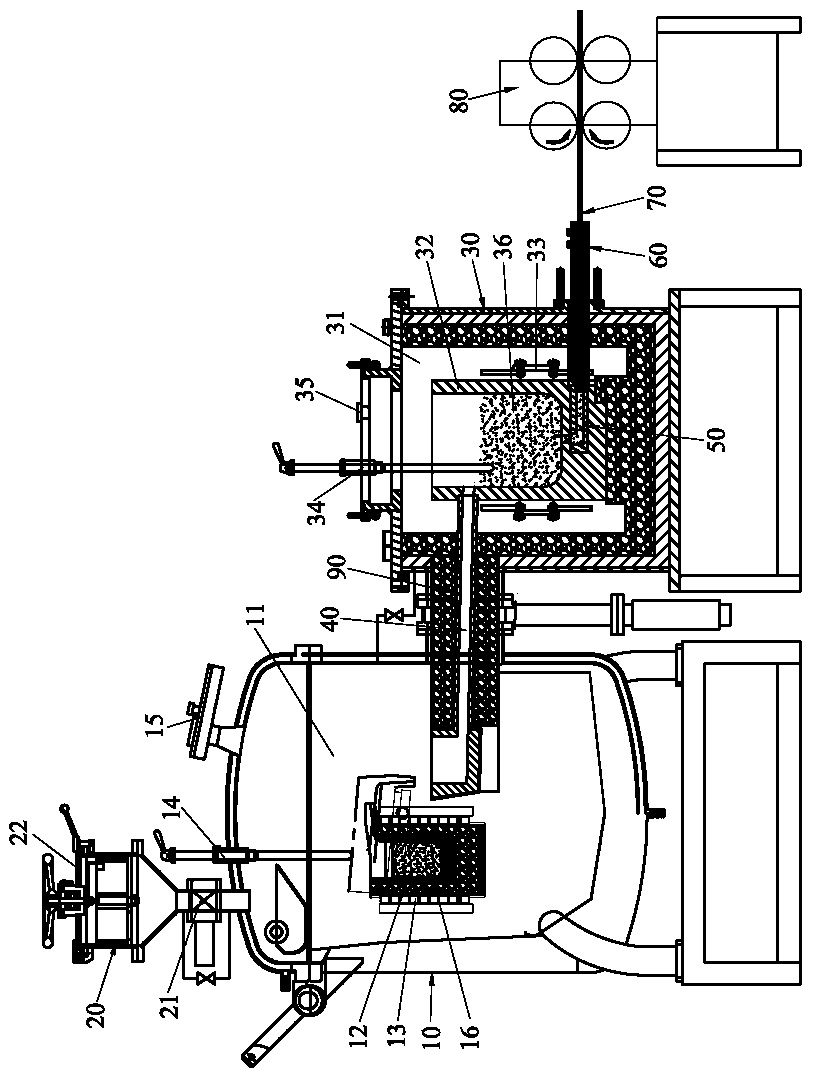

A vacuum continuous melting and casting device for copper alloy

The invention discloses a copper alloy vacuum continuous smelting casting device. The copper alloy vacuum continuous smelting casting device includes a vacuum smelting chamber, a continuous vacuum feeding chamber, a vacuum casting chamber, an upper flow groove, a lower flow groove, a crystallizer, a dummy bar head and a traction machine. The vacuum smelting chamber is provided with a smelting cavity. The smelting cavity is internally provided with a smelting crucible capable of being tilted and returning to the origin. An induction coil is arranged on the melting crucible. The vacuum casting chamber is provided with a casting cavity. A casting crucible is arranged in the casting cavity. The outer side surface of the casting crucible is provided with a heating element. According to the copper alloy vacuum continuous smelting casting device, through matching and using of the vacuum melting chamber, the continuous vacuum feeding chamber, the vacuum casting chamber, the upper flow groove,the lower flow groove, the crystallizer, the dummy bar head and the traction machine, vacuum continuous feeding, continuous smelting and continuous casting are achieved, easily-oxidized metal can be smelted, the stability of alloy texture is ensured, degassing and refining can be conducted on a melt body through vacuum degree adjustment, and the service lives of parts such as the crucible and theflow grooves can be prolonged.

Owner:JIANGXI UNIV OF SCI & TECH

A kind of preparation method of carbon fiber uniform electroplating copper layer

The invention discloses a method for preparing a uniform electroplated copper layer of carbon fibers. The method comprises: (1) desizing carbon fibers; (2) fixing carbon fibers; In the electroplating tank containing the electroplating solution, adjust the distance between the cathode and the anode to be 4-10cm, and keep the current density at 0.80-1.00mA / cm 2 , the voltage is 1.5-3.0V, the electroplating temperature is 10-30°C, and the electroplating is 60-90min. Among them, the electroplating solution contains: CuSO 4 ·5H 2 O, C 4 h 4 o 6 KNa·4H 2 O, C 6 h 5 Na 3 o 7 2H 2 O. KNO 3 , polyethylene glycol, NaCl and water. The method of the invention can change the thickness, uniformity and surface appearance of the carbon fiber copper coating after electroplating by controlling the composition, concentration and current density of the electroplating solution, and the coating has good and uniform bonding force and no bonding between carbon fibers.

Owner:SICHUAN UNIV

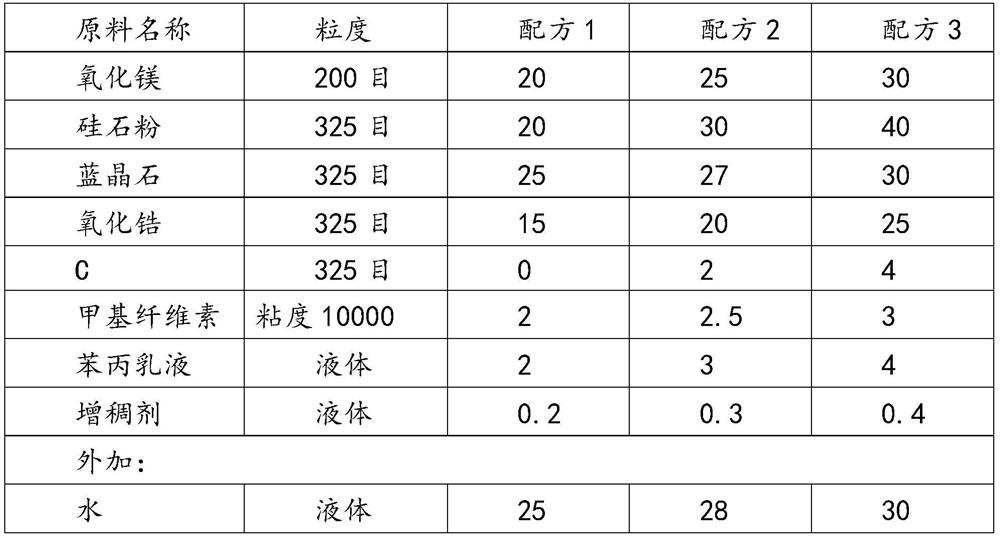

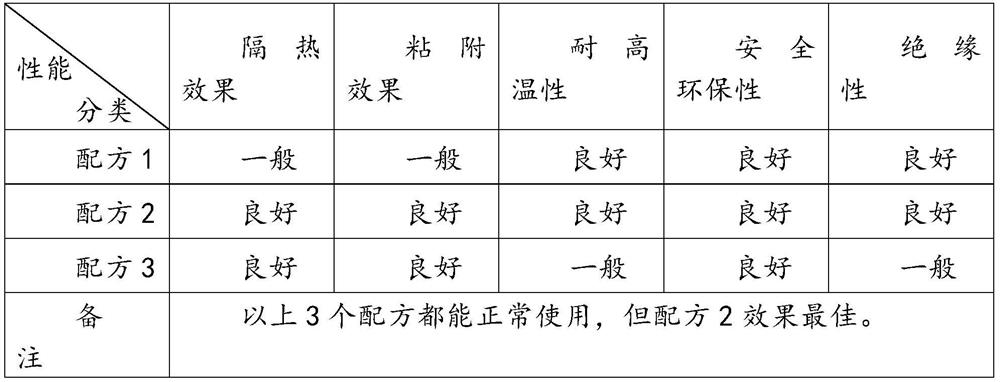

High-temperature air-leakage-proof expansion coating for tundish sleeve, and preparation method thereof

PendingCN113861728AImprove the effect of argon sealingEmbrittlement will notFireproof paintsCelluloseMeth-

The invention discloses a high-temperature air-leakage-proof expansion coating for a tundish sleeve. The expansion coatingcomprises, by weight, 2-3% of methyl cellulose, 2-4% of styrene-acrylic emulsion, 0.2-0.4% of a thickening agent, 20-30% of high-purity magnesium oxide, 20-40% of silica powder, 25-30% of kyanite, 15-25% of zirconium oxide, 0-4% of C and 25-30% of water. The invention aims to provide the high-temperature air-leakage-proof expansion coating for the tundish sleeve, which is free of environmental pollution, good in heat insulation effect, high-temperature-resistant and good in sealing effect, and a preparation method of the high-temperature air-leakage-proof expansion coating.

Owner:无锡市南方耐材有限公司

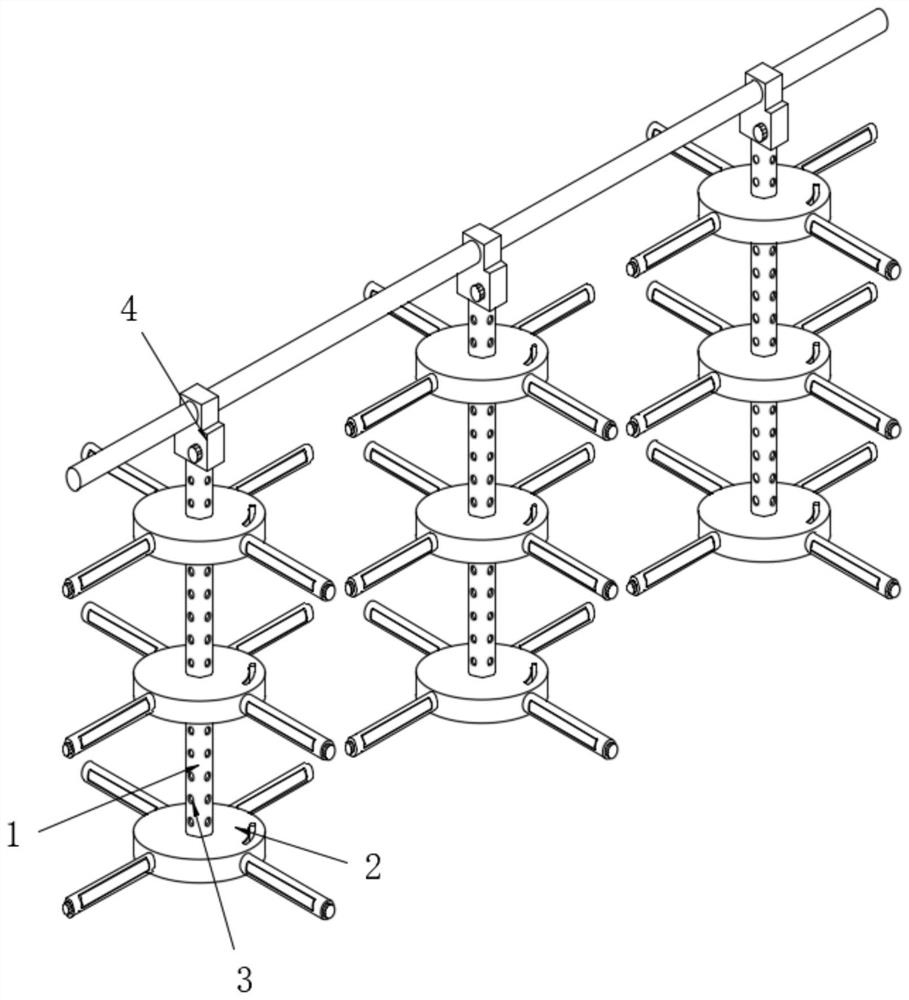

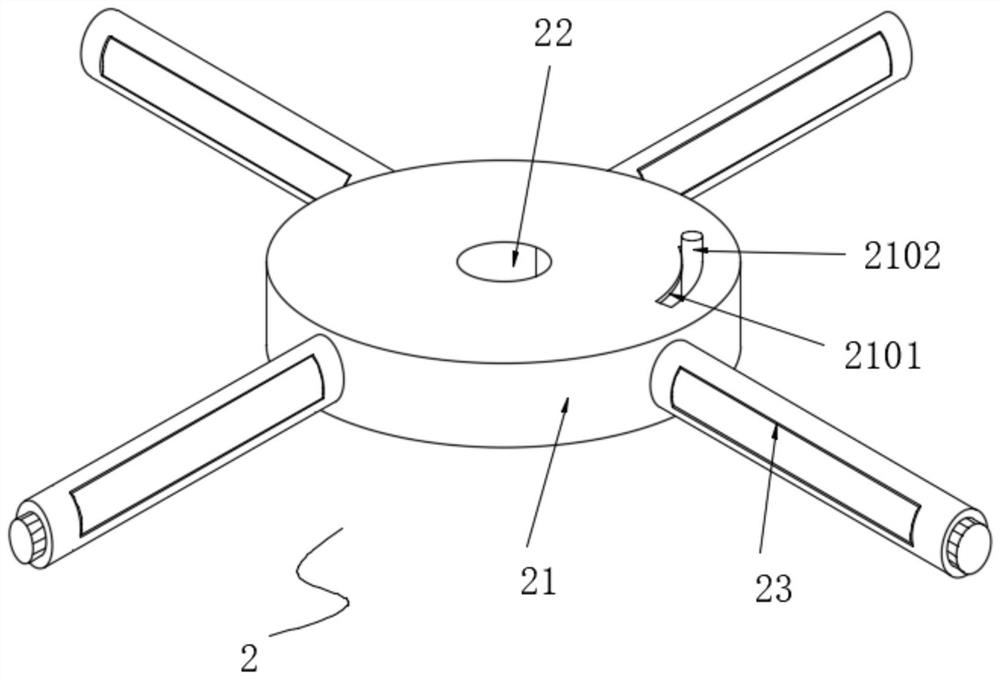

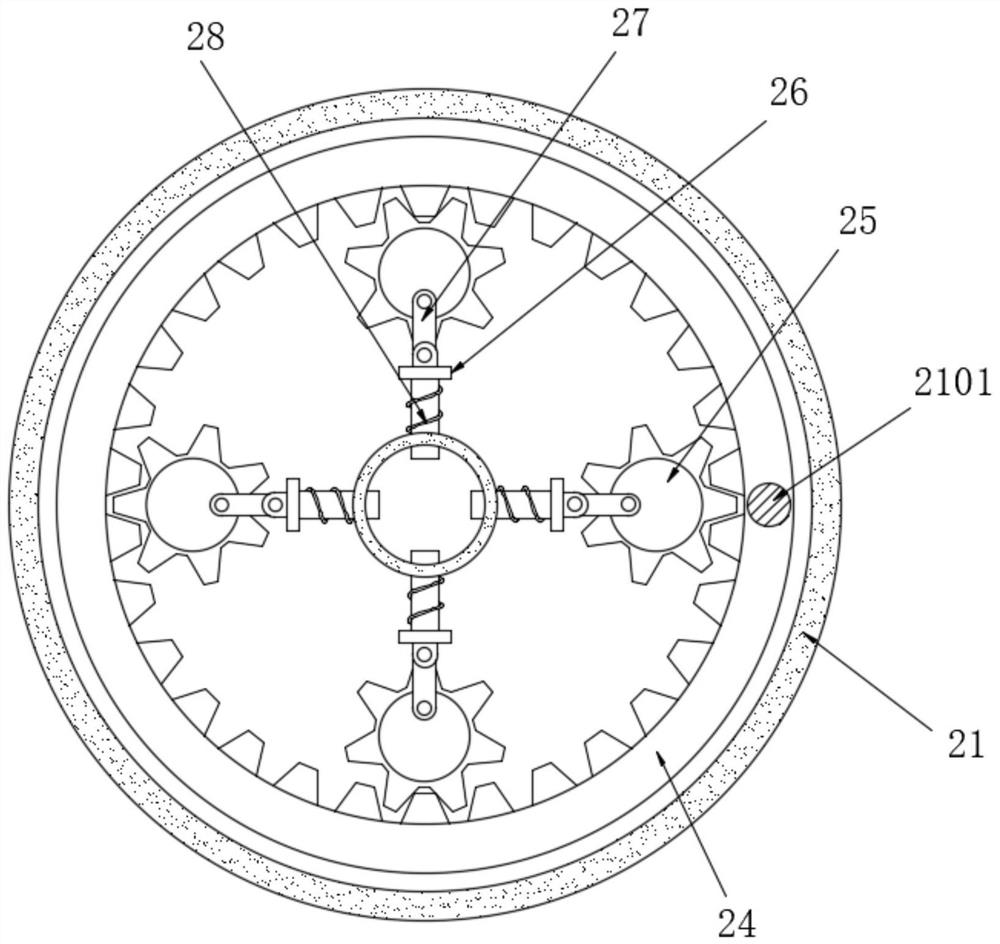

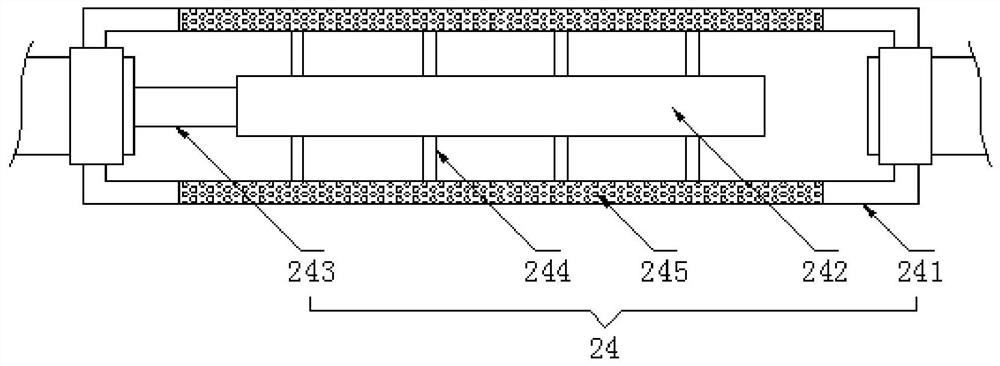

Secondary vulcanization shaping equipment for rubber tube

PendingCN114800967AGuaranteed firmnessImprove the scope of applicationTubular articlesComposite materialEngineering

The invention discloses secondary vulcanization shaping equipment for a rubber tube, relates to the technical field of rubber tube vulcanization, and aims to solve the problems that no good device is used for vulcanizing the shaped rubber tube at present, and the existing rubber tube vulcanization shaping equipment is inconvenient to adjust, cannot obtain a better vulcanization effect and cannot perform shaping work on rubber tubes with different diameters. Comprising a plurality of limiting shafts, the outer surface of each limiting shaft is sleeved with a plurality of shaping pieces in a sliding mode, a plurality of rows of positioning holes are formed in the outer surface of each limiting shaft at equal intervals, each row of positioning holes are divided into four positioning holes at equal intervals, and limiting pieces are fixedly connected between the upper ends of the limiting shafts. According to the secondary vulcanization shaping equipment for the rubber pipe, after the rubber pipe is shaped, the distance between the shaping parts can be conveniently adjusted, the rubber pipe is prevented from being bonded together in the vulcanization process, and the secondary vulcanization effect of the rubber pipe can be improved.

Owner:徐州市华为工程机械有限公司

A kind of copper alloy vacuum continuous melting and casting method

The invention discloses a vacuum continuous melting casting method for a copper alloy, which adopts a vacuum continuous melting casting device for the copper alloy. The device comprises a vacuum melting chamber, a continuous vacuum feeding chamber, a vacuum casting chamber, an up-flow groove, a down-flow groove, a crystallizer, a dummy bar head and a traction machine; a melting cavity is formed inthe vacuum melting chamber; a melting crucible which can be inclined and returned is arranged in the vacuum melting chamber; an induction coil is arranged on the melting crucible; a casting cavity isformed in the vacuum casting chamber; a casting crucible is arranged in the vacuum casting chamber; a heating element is arranged on the outer side surface of the casting crucible; through cooperatedutilization of the vacuum melting chamber, the continuous vacuum feeding chamber, the vacuum casting chamber, the up-flow groove, the down-flow groove, the crystallizer, the dummy bar head and the traction machine, the vacuum continuous feeding, continuous melting and continuous casting are realized; a metal which is easy to oxidize can be molten; the stability of alloy components is ensured; degassing defining can be performed on a melt by adjusting the vacuum degree; and the service lives of the products, such as the crucibles and the flow grooves, can be prolonged.

Owner:JIANGXI UNIV OF SCI & TECH

Desulfurized gypsum vertical type rotary water extractor with excellent sealing effect

InactiveCN111721101AEasy dischargeImprove efficiencyDrying machine combinationsDrying gas arrangementsElectric machineryStructural engineering

The invention discloses a desulfurized gypsum vertical type rotary water extractor with an excellent sealing effect and belongs to the technical field of desulfurized gypsum. The desulfurized gypsum vertical type rotary water extractor comprises a feeding case; a feeding pipeline communicates with the outer wall of the left side of the feeding case; a feeding plate is arranged on the inner wall ofthe feeding pipeline; a flip cover is arranged on the outer wall of the left side of the feeding case; an electric push rod is arranged on the left side of the top of the feeding case; a drying machine is arranged on the top of the feeding case; a blast pipe is connected with the bottom of the drying machine; an air-drying plate is arranged in the cavity of the feeding case; a stepping motor is arranged on the outer wall of the right end of the feeding case; and the output end of the stepping motor is connected with a packing auger to rapidly discharge water vapor, so that a higher efficiencyis ensured when the material is preliminarily dewatered, the material is not glued together, the material is separated to accelerate the drying speed and is heated uniformly in an outer housing, thematerial heating dewatering efficiency is ensured, and the overall difficulty of material drying is lowered.

Owner:刘永

Device for automatically cleaning concrete of tank of concrete mixer truck

InactiveCN109291252AWill not bondAvoid pouringTransportation and packagingMixer accessoriesTruckEngineering

The invention belongs to the technical field of car cleaning, and specifically relates to a device for automatically cleaning concrete of a tank of a concrete mixer truck. The device comprises a vibrating device which is arranged on the tank and can reciprocate as the tank rotates, wherein blades are arranged on the inner wall of the tank. The invention also comprises a magnetic attracting body which is arranged on the vibrating device. The device can automatically work as the tank rotates, and special operation is saved; and the device is simple in structure, convenient to operate, and high in efficiency.

Owner:龚正圣

A method for encapsulating organic scintillation crystals

ActiveCN109085640BAvoid secondary reactionsGood light transmission performanceRadiation measurementCrystallographyPhysical chemistry

The invention discloses a packaging method for organic scintillation crystals. The packaging method comprises silicone rubber casting, placement of organic scintillation crystals, vacuum exhaust molding, and room temperature radiation curing. The packaging method of the organic scintillation crystal of the present invention can save the processing steps of the organic scintillation crystal, reduce the reduction of the volume of the organic scintillation crystal and the decrease of the fluorescence intensity caused by the processing, and the cast silicone rubber can not only realize the fixation of the organic scintillation crystal, It can also enhance the shock resistance of organic scintillation crystals.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

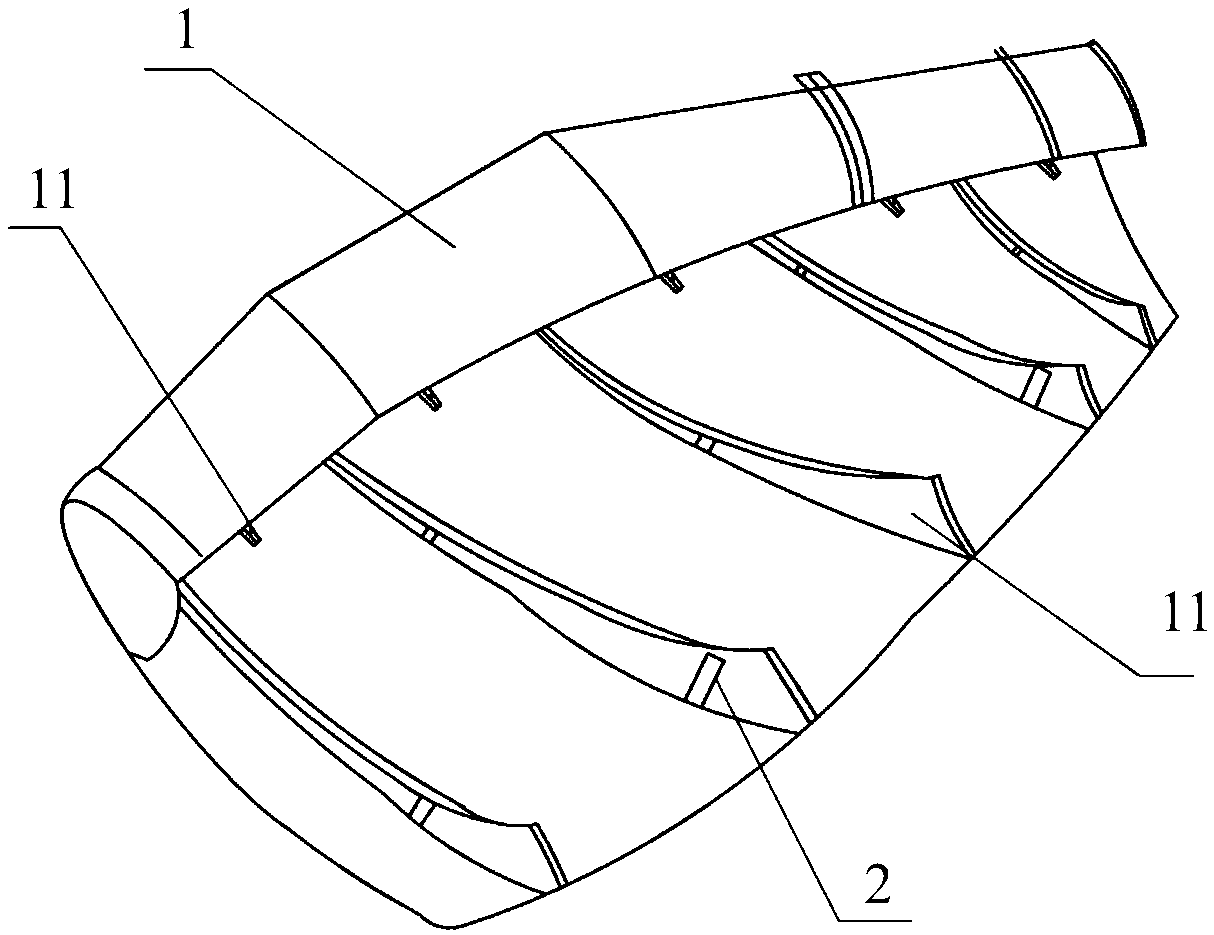

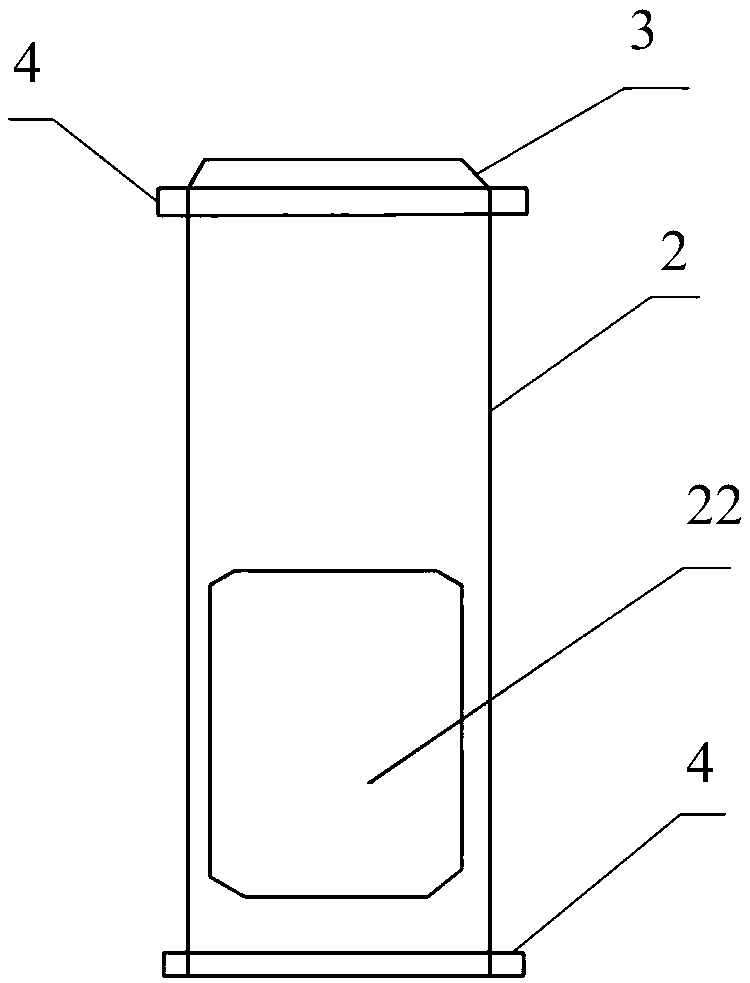

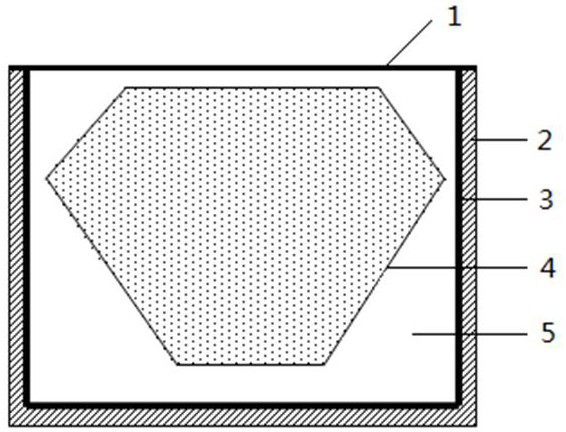

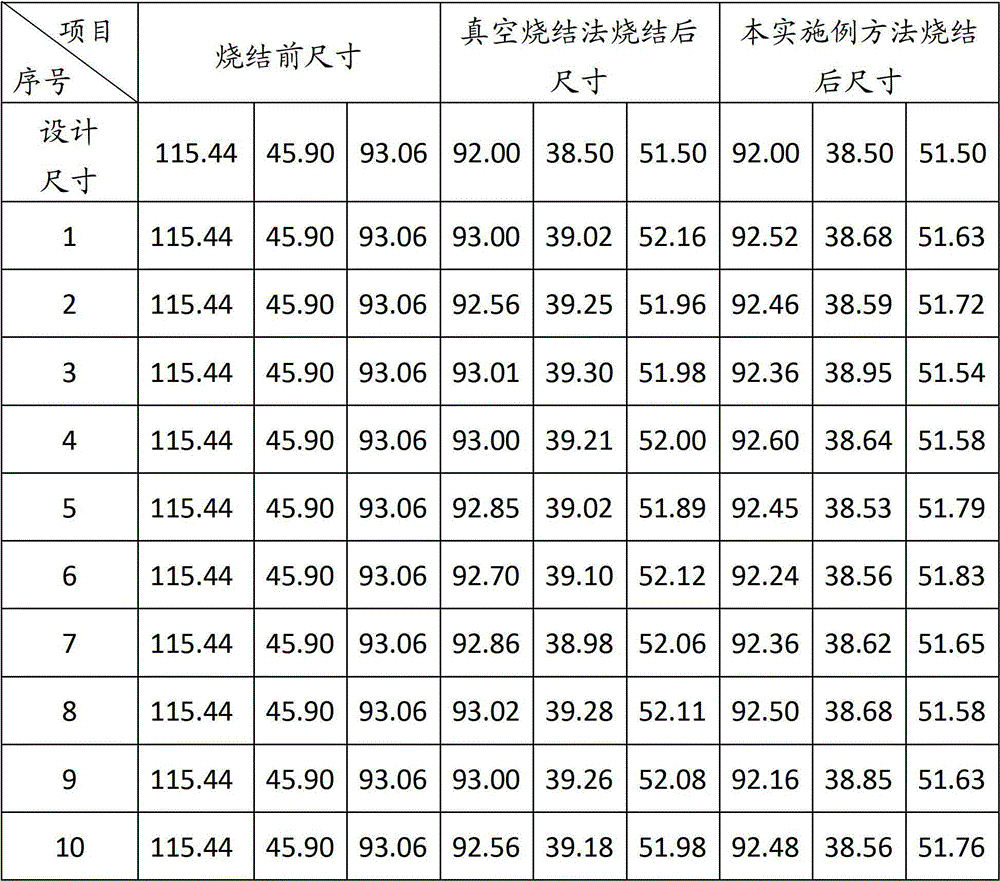

Sintering method of NdFeB magnet

ActiveCN103506624BPrevent oxidationSmall machining allowanceInductances/transformers/magnets manufactureMagnetic materialsMetallurgyMachining

The invention discloses a method for sintering neodymium iron boron magnets. The method for sintering the neodymium iron boron magnets is characterized by comprising the following steps of (1) preparation, wherein neodymium iron boron green bodies are buried in high-temperature resisting powder to enable the neodymium iron boron green bodies to be isolated from air, and the sintering temperature of the high-temperature resisting powder is higher than that of the neodymium iron boron magnets; (2) furnace feeding, wherein the neodymium iron boron green bodies and the high-temperature resisting powder are fed into a sintering space in the furnace together; (3) sintering, wherein the neodymium iron boron green bodies are sintered to form the neodymium iron boron magnets. The method can reduce the oxidation of the neodymium iron boron green bodies before the neodymium iron boron green bodies are fed into the furnace, therefore, sintering deformation is reduced, reserved allowance for the machining of the neodymium iron boron green bodies is reduced, and subsequent machining is made to be convenient.

Owner:SINO MAGNETICS TECH

High-density modified plastic particle cooling device

The invention relates to a high-density modified plastic particle cooling device, which belongs to the technical field of plastic cooling. The device comprises a first cooling assembly, the first cooling assembly comprises a feed hopper, a first fan located above the feed hopper and a cooling net fixed on the inner wall of the bottom end of the feed hopper, two support plates are arranged below the first feed hopper, a supporting rod for supporting the feeding hopper is fixed on the upper surface of the supporting plate, a cavity is formed in the side wall of the feeding hopper, a first waterinlet pipe is fixed to the bottom end of the side wall of the feeding hopper, and a first water outlet pipe is fixed to the top end of the feeding hopper, a conveying assembly is arranged below the feeding hopper and comprises a conveying belt and a second cooling water pipe, the conveying belt is installed between the two supporting plates, and the second cooling water pipe is installed on the inner side of the conveying belt. The plastic particle cooling device has the characteristic of improving the cooling effect of plastic particles.

Owner:浙江腾峰五金塑料有限公司

Rubber sealing ring

The invention relates to the field of sealing rings, in particular to a rubber sealing ring which comprises an upper ring and a lower ring integrally connected with the bottom of the upper ring, through holes are formed in the upper ring and the lower ring in a penetrating mode, and the two through holes are integrally formed and are the same in diameter; the top of the upper ring is provided with a pressing mechanism, and the outer wall of the lower ring is connected with a fastening mechanism. The outer sealing ring tightly abuts against the inner wall of the heat preservation barrel cover, and the outer sealing ring and the inner wall of the heat preservation barrel cover are fully sealed, so that good sealing performance is achieved between the upper ring and the heat preservation barrel cover, water in the heat preservation barrel is not prone to entering the space between the sealing ring and the heat preservation barrel cover, residual water between the sealing ring and the heat preservation barrel cover is reduced, and the service life of the heat preservation barrel is prolonged. And therefore, the bacteria breeding environment is reduced, and the heat preservation barrel cover is safer and more sanitary in use.

Owner:郭腾飞

Automatic corrugated board production equipment and production method thereof

InactiveCN113211891ASimple structureWon't overflowMechanical working/deformationAdhesive glueCorrugated fiberboard

The invention discloses corrugated board production equipment which comprises a box body, a plurality of support blocks are arranged at the top of the box body, the support blocks are symmetrically arranged front and back, the support blocks clamp the front side and the rear side of corrugated paper, and limiting devices capable of abutting against and limiting the front side and the rear side of the corrugated paper according to the corrugated paper with different thicknesses are arranged in the support blocks. A cutting device used for cutting corrugated paper is arranged at the top of the box body, a sliding connecting plate is arranged in the box body in a sliding mode, an internal thread moving block is arranged in the sliding connecting plate in a sliding mode, and a smearing device used for smearing glue on the corrugated paper is arranged on one side of the internal thread moving block. According to the equipment, corrugated paper can be clamped on the front side and the rear side according to corrugated paper of different widths, the corrugated paper can be cut off at a fixed distance and then the upper side of the corrugated paper is smeared with glue liquid, and glue liquid cannot overflow and drip.

Owner:南京波诗纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com