Manufacturing process for lateral plate of electric cabinet

A manufacturing process and technology for electrical cabinets, applied in the field of electrical cabinets, can solve the problems of messy wires, easy bonding, and high probability of electrical cabinet failure, and achieve the effect of reducing the probability of failure and orderly wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

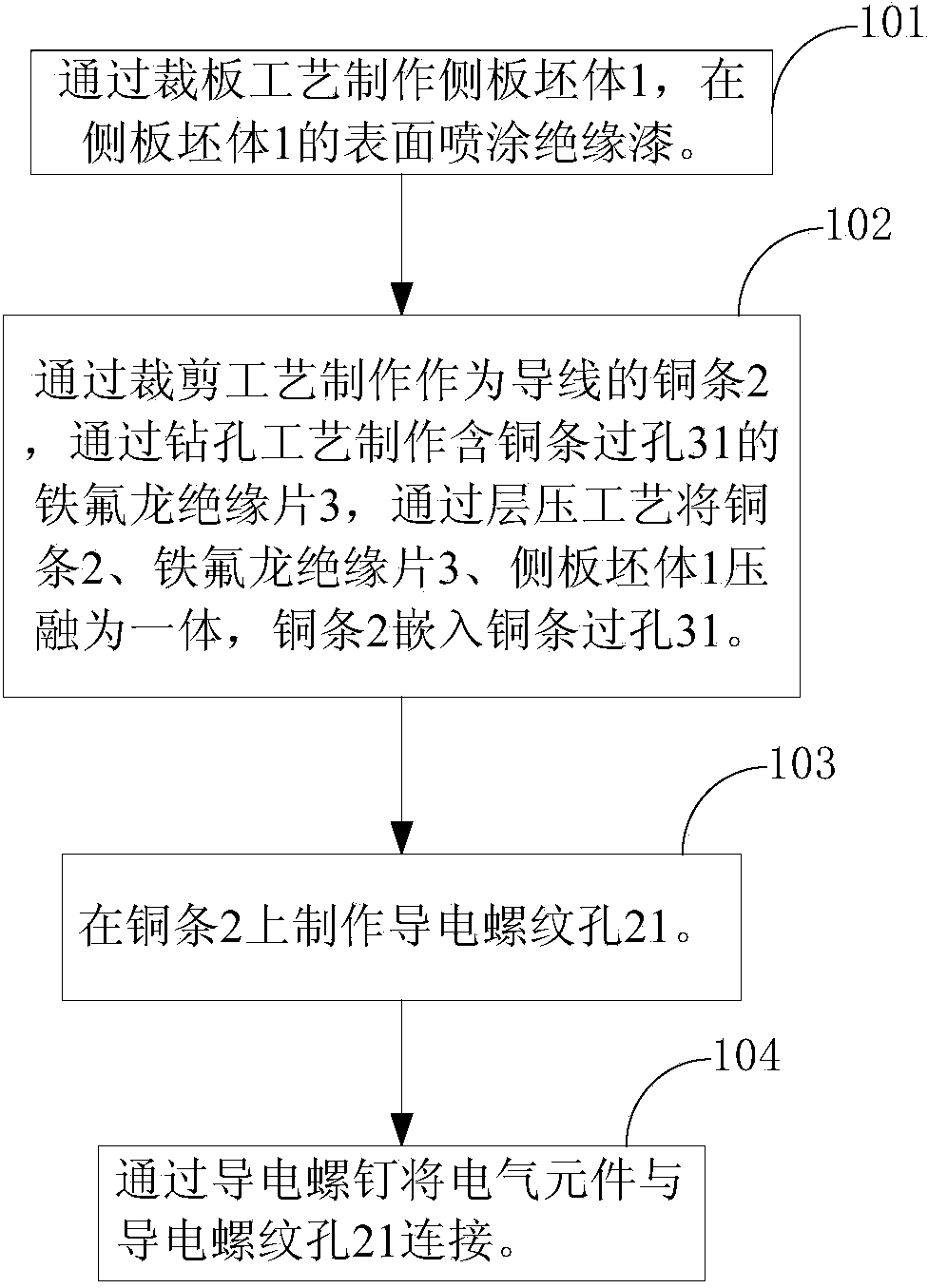

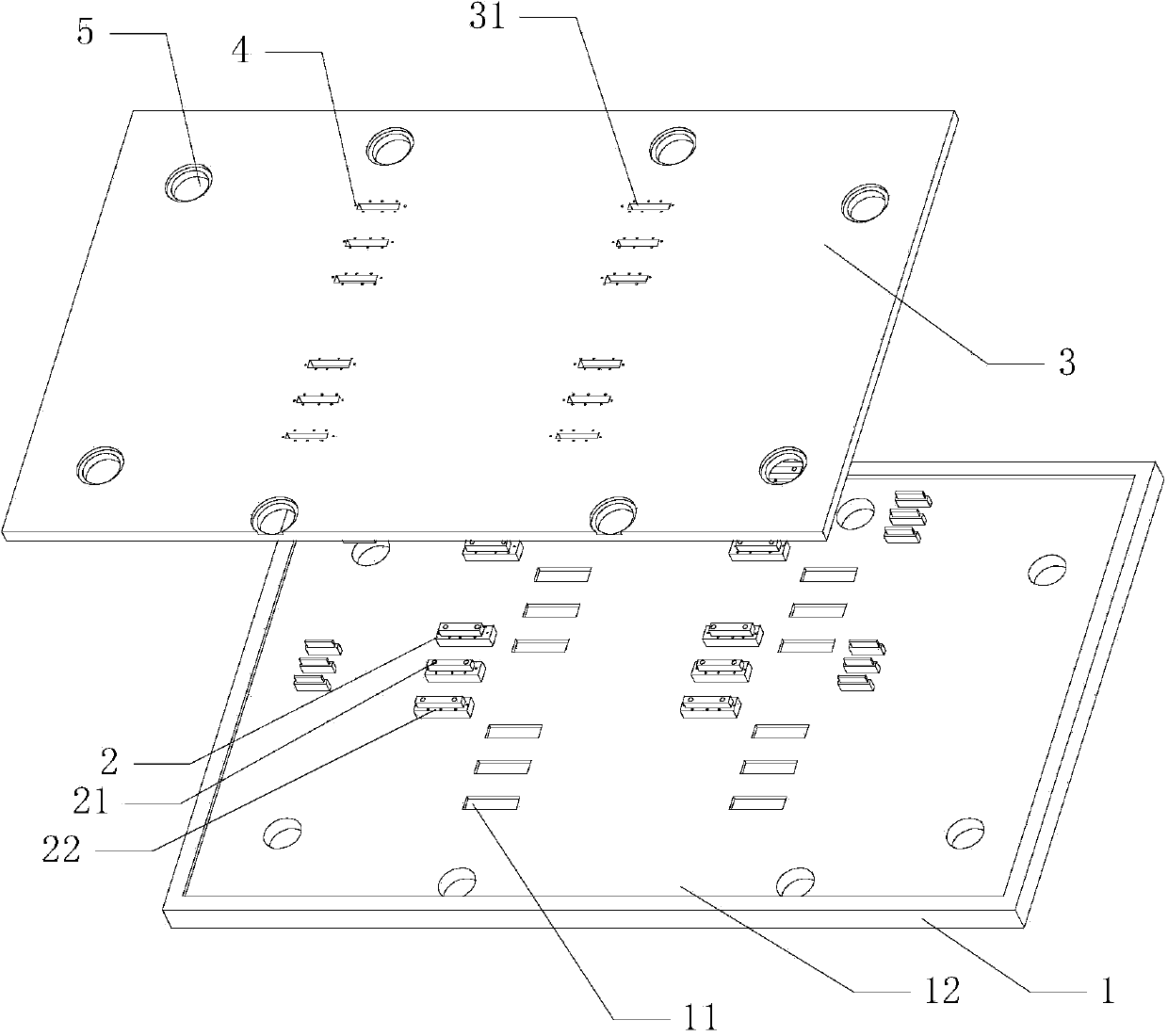

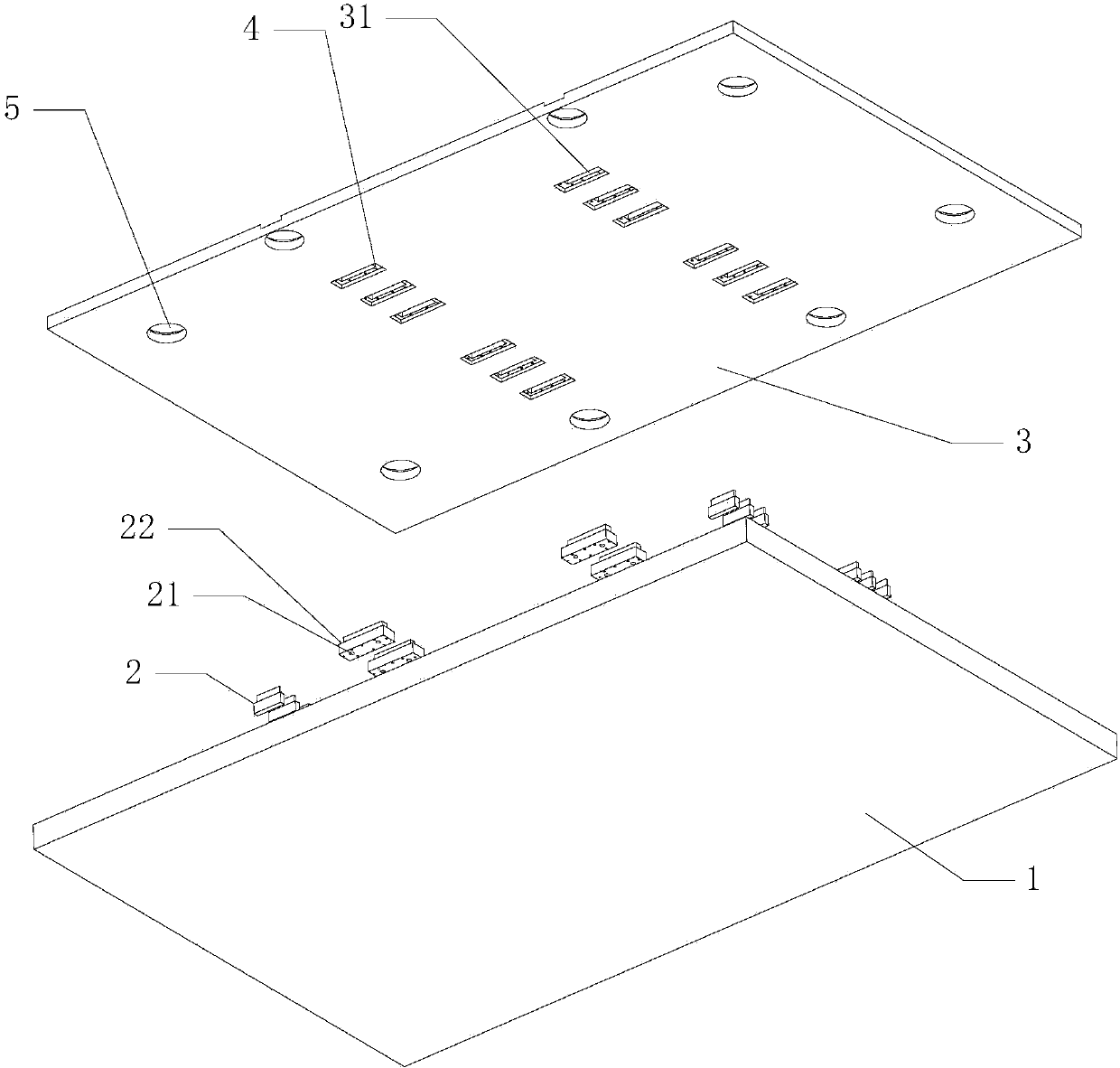

[0023] The present invention provides a manufacturing process of a side panel of an electrical cabinet. In order to enable those skilled in the art to understand the solution of the present invention more clearly, and to make the above-mentioned purpose, characteristics and beneficial effects of the present invention clearer and easier to understand, Attached below Figure 1~3 The present invention will be further described in detail with specific embodiments.

[0024] A manufacturing process of a side panel of an electrical cabinet, comprising:

[0025] Step 101. Fabricate the side panel base body 1 through a panel cutting process, and spray insulating paint on the surface of the side panel base body 1 .

[0026] Step 102. Make the copper strip 2 as the wire by the cutting process, make the Teflon insulating sheet 3 containing the copper strip via hole 31 by the drilling process, and make the copper strip 2, the Teflon insulating sheet 3, the side by the lamination process. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com