Intelligent casting island

An intelligent and main technology, applied in the field of casting, can solve problems such as affecting the normal service life of casting equipment, thermal fatigue of casting equipment, and easy deformation of components, so as to achieve the effect of realizing mold protection, ensuring airflow, and facilitating placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

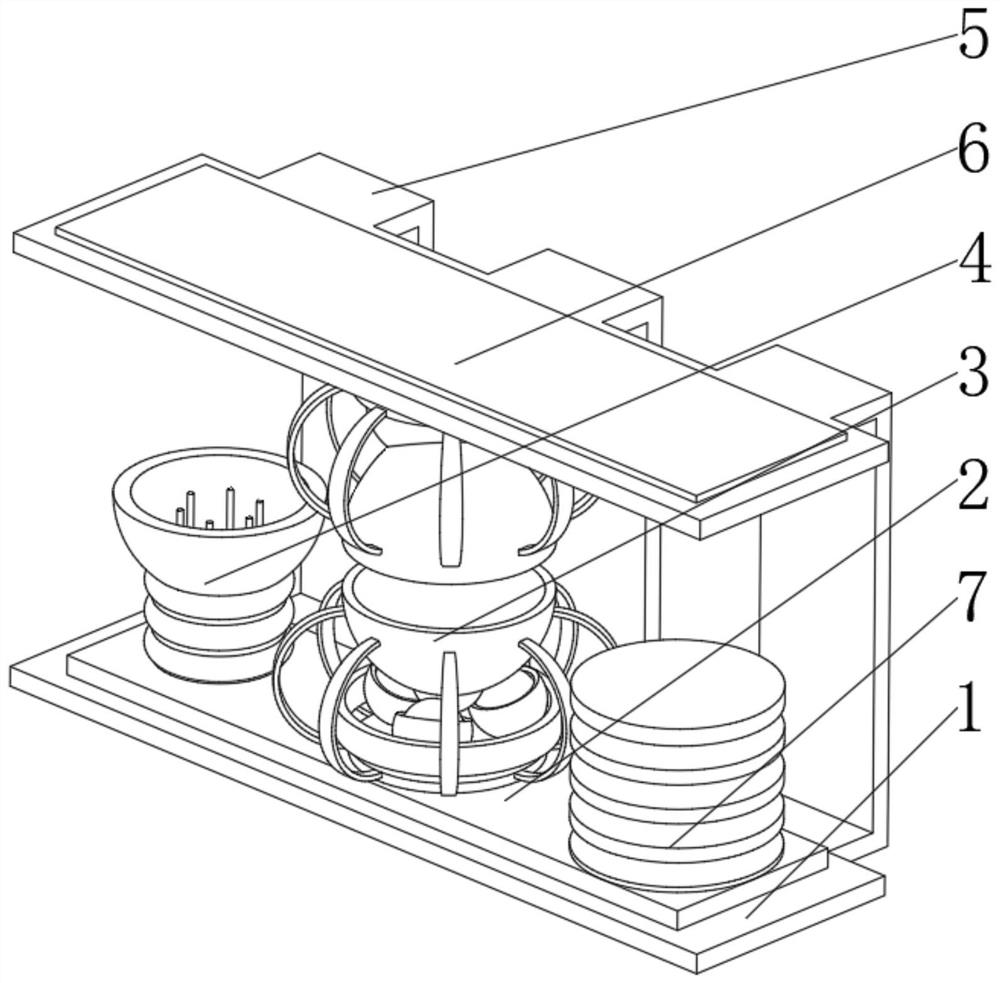

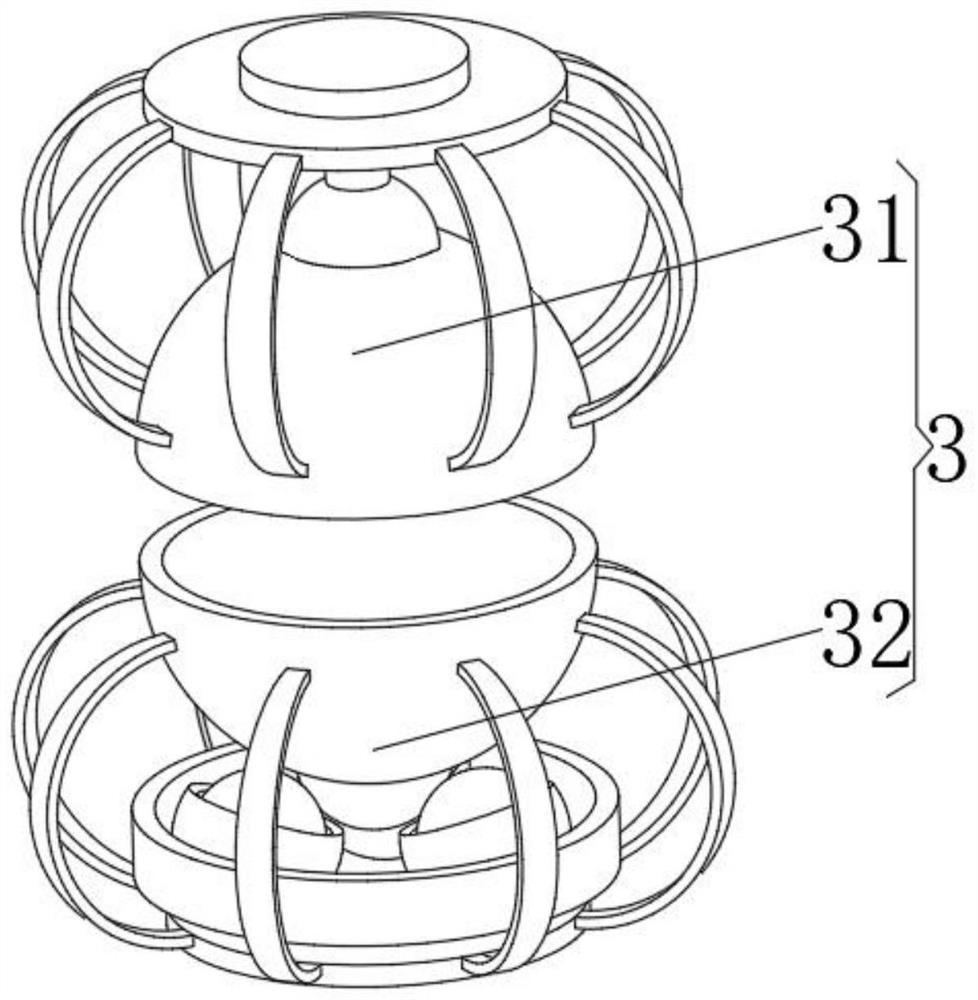

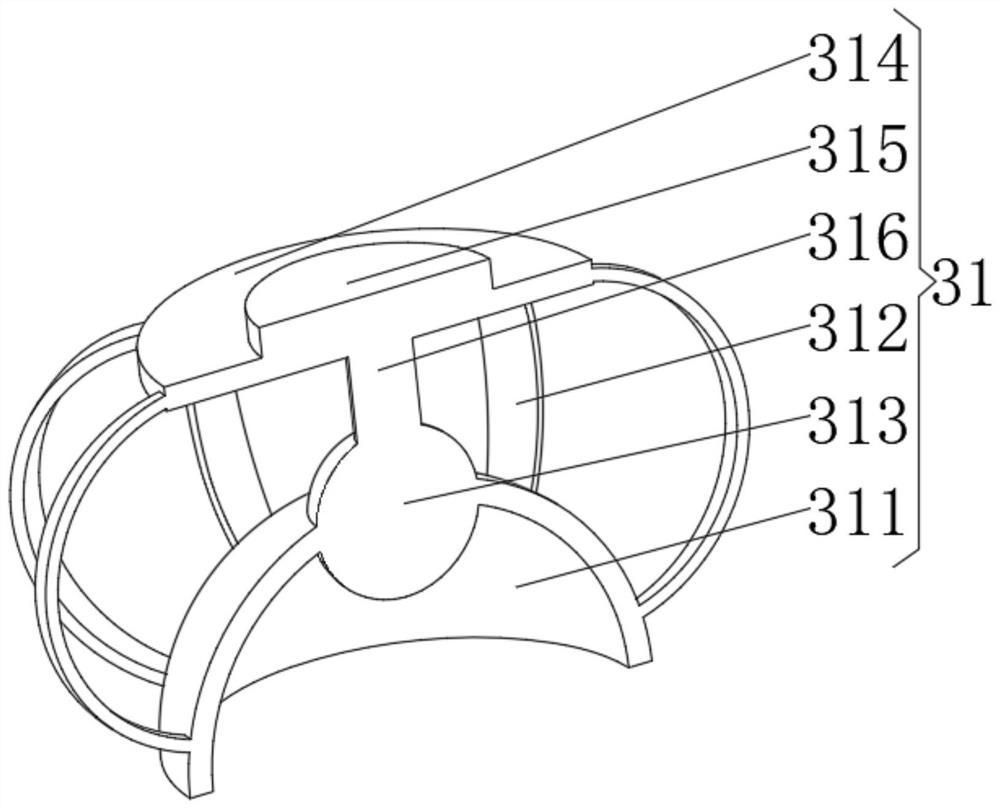

[0043] see Figure 1-4 , the present invention provides a technical solution: an intelligent casting island, specifically comprising:

[0044] Support seat 1, the support seat 1 has a rectangular seat plate, and a lifter 2 installed on the top of the rectangular seat plate, and a die mechanism 3 installed in the middle of the top of the lifter 2, and a lifter 2 installed on the left side of the top The liquid injection mechanism 4, and the material receiving platform 7 installed on the right side of the lifter 2 top, and the support frame 5 installed on the back of the rectangular seat plate, and the driving track 6 installed on the top of the support frame 5 pass through the rectangular support seat 1. The seat plate design extends the path length of the process, prolongs the movement time during the movement of the equipment mechanism, facilitates the temperature reduction of the mechanism after casting, avoids thermal fatigue caused by continuous casting processing of compone...

Embodiment 2

[0060] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: the liquid injection mechanism 4 includes an airbag column 41, and an object cover 42 installed on the airbag column 41, and an object mounted on the inner surface of the object cover 42 The positioning cannula 43 and the liquid injection tube 44 installed in the middle of the bottom of the carrier cover 42 , and the top of the liquid injection tube 44 communicates with the positioning cannula 43 , and the liquid injection tube 44 is located in the inner cavity of the airbag column 41 . Through the liquid injection mode from bottom to top, it is more suitable for the suction of mold air by negative pressure, and at the same time, the counterflow of casting liquid from bottom to top prolongs the time of liquid injection, and the flow of casting liquid is more uniform and thorough during liquid injection.

[0061] The bottom of the airbag column 41 and the liquid injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com