Process for treating ammonia-nitrogen waste water

A technology for ammonia nitrogen wastewater and treatment methods, which is applied in the direction of combustion methods, osmosis/dialysis water/sewage treatment, chemical instruments and methods, etc., can solve the problems of ineffective treatment of high-concentration ammonia nitrogen wastewater, ammonia nitrogen wastewater discharge standards, etc., to achieve waste discharge Less, low operating costs, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

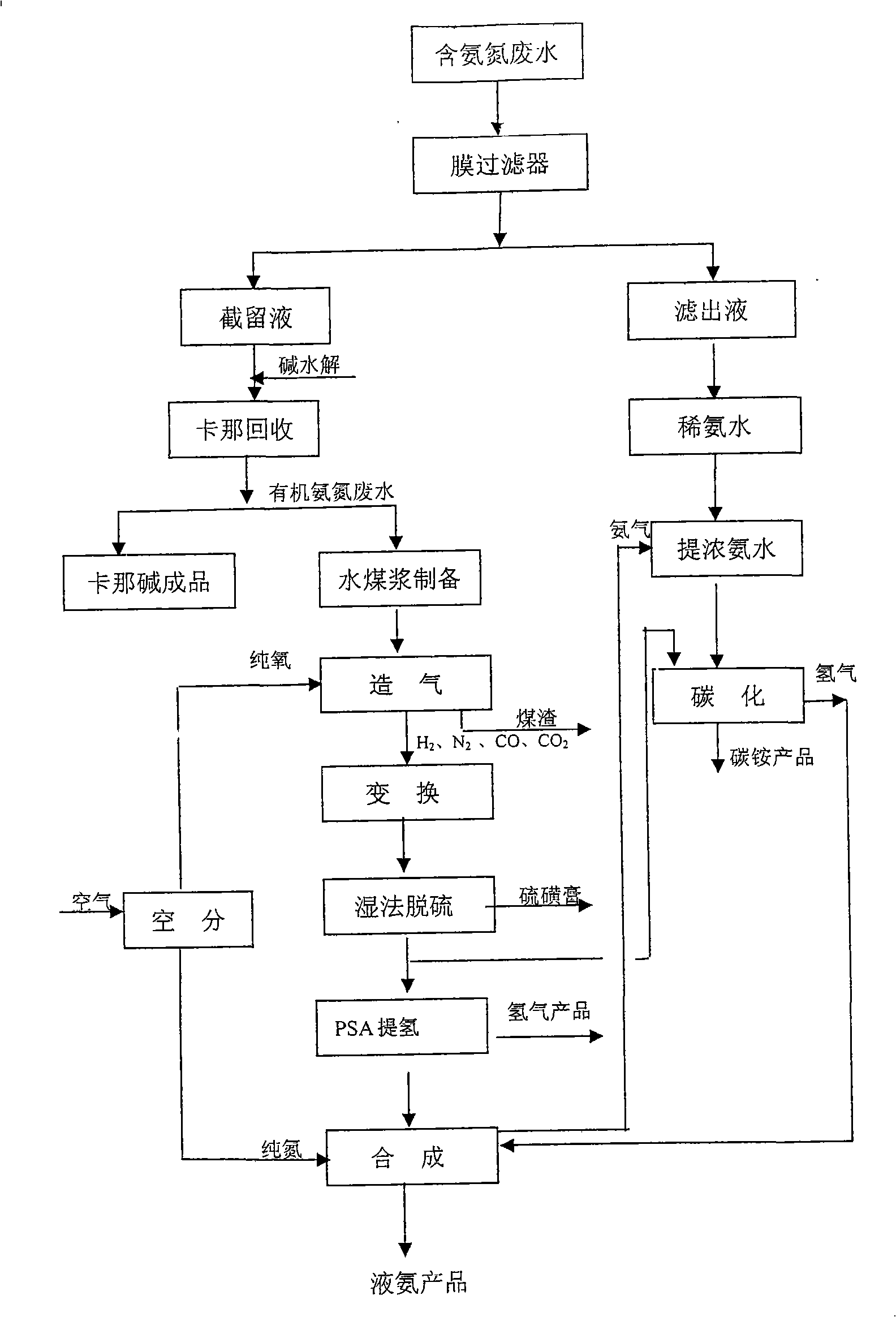

[0009] The main production process includes membrane filtration, kana recovery, ammonia water concentration, coal water slurry preparation, gas generation, conversion, wet desulfurization, PSA hydrogen extraction, synthesis and other steps.

[0010] Ammonia nitrogen waste water (flow rate 10.5-12.3 tons / hour) produced in the production process of amikacin is firstly filtered through a membrane filter, and the filtrate is ammonia containing 0.5%-0.6% (flow rate 8-9 tons / hour) Dilute ammonia water enters the isobaric recovery process to prepare concentrated ammonia water, which is then carbonized to produce ammonium bicarbonate. The retentate (flow rate: 2.5-3.3 t / h) enters the Kanakine recovery device, where Kanakine is extracted after hydrolysis and reused in the production of Amikacin. The organic waste water containing 3-5% ammonia nitrogen produced by kanaine recovery is pumped into the pulping process to prepare coal water slurry; the coal water slurry with a concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com