Process method for co-producing ammonium bicarbonate by using coking plant waste

An ammonium bicarbonate and process method technology, applied in the chemical industry, ammonium carbonate/acid carbonate, sustainable manufacturing/processing, etc., to achieve obvious economic and social benefits, simple process flow, and pollution prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

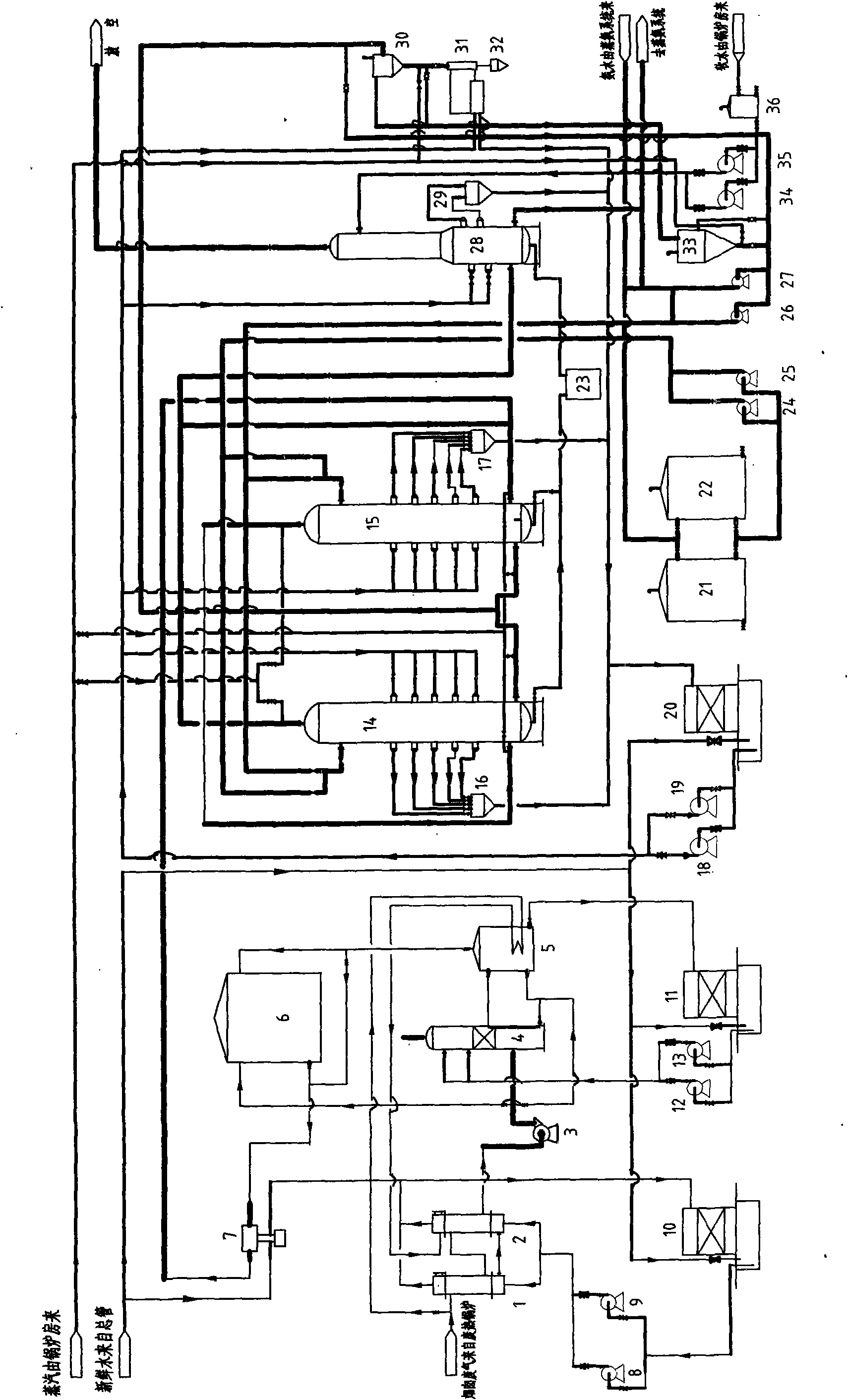

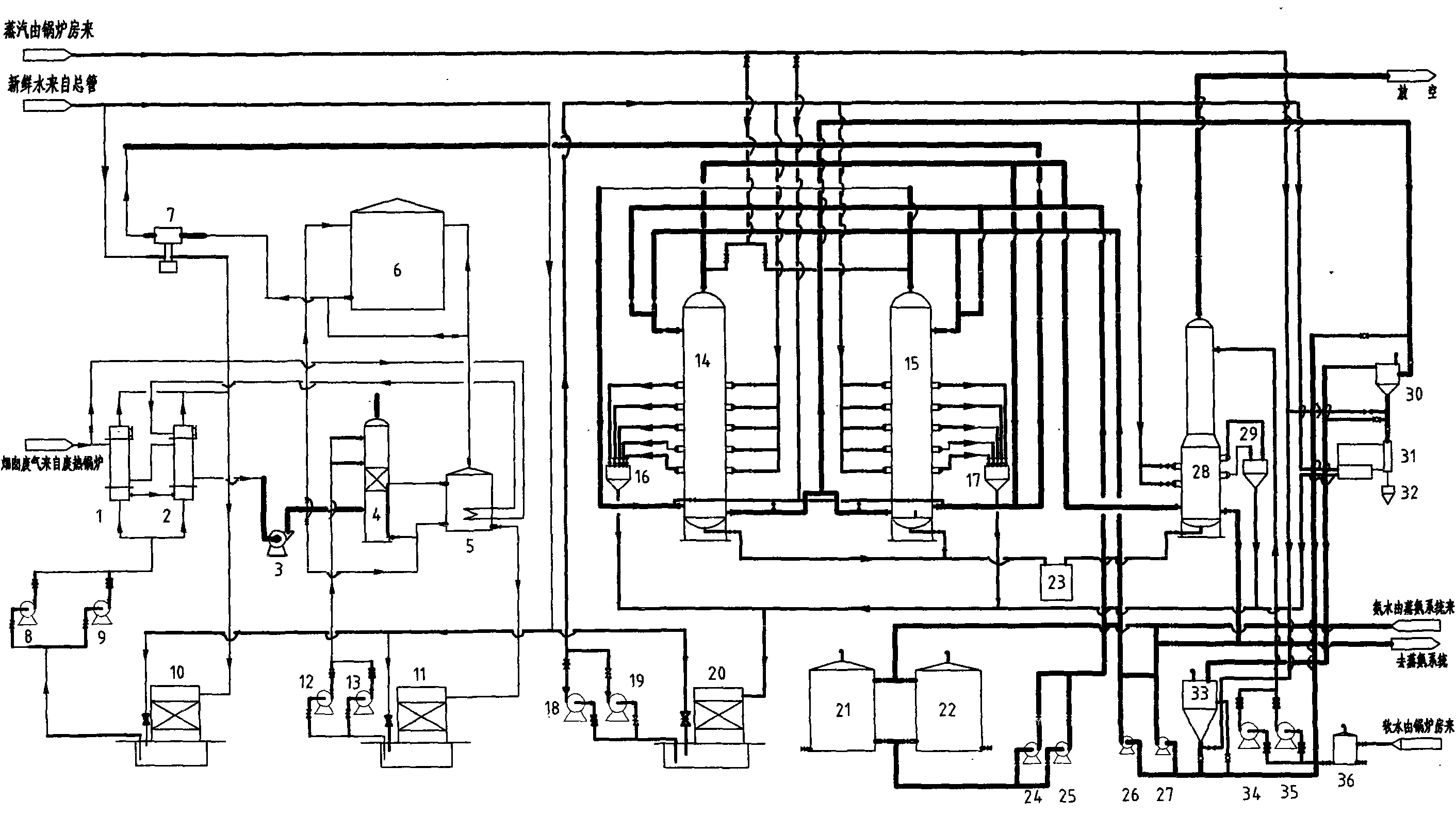

[0030] The following is based on figure 1 The shown process flow diagram further illustrates the technical solution of the present invention.

[0031] From figure 1 As can be seen:

[0032] Step 1: The waste gas at about 260°C from the chimney goes through heat exchangers 1 and 2 to cool down to 40-50°C step by step, and then divides into two paths. One path passes through the fan 3 and directly enters the gas storage tank 6, and the other path enters the absorption After the tower 4 is washed and attached, it enters the concentration tank 5 for heating and stirring by using the natural pressure difference to increase the CO 2 The concentration of high concentration CO from the concentration tank 5 2 The gas enters the gas holder 6 with a low concentration of CO 2 Gas mixing ready for use;

[0033] The second step: waste liquid treatment process

[0034] Enter the ammonia water tank 21 and 22 for stand-by through distillation by the waste ammonia water of the ammonia dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com