Treatment method for high-ammonia-nitrogen wastewater

A treatment method, high ammonia nitrogen technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The problem of high cost, to achieve the effect of reducing turbidity, reducing the risk of scaling, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

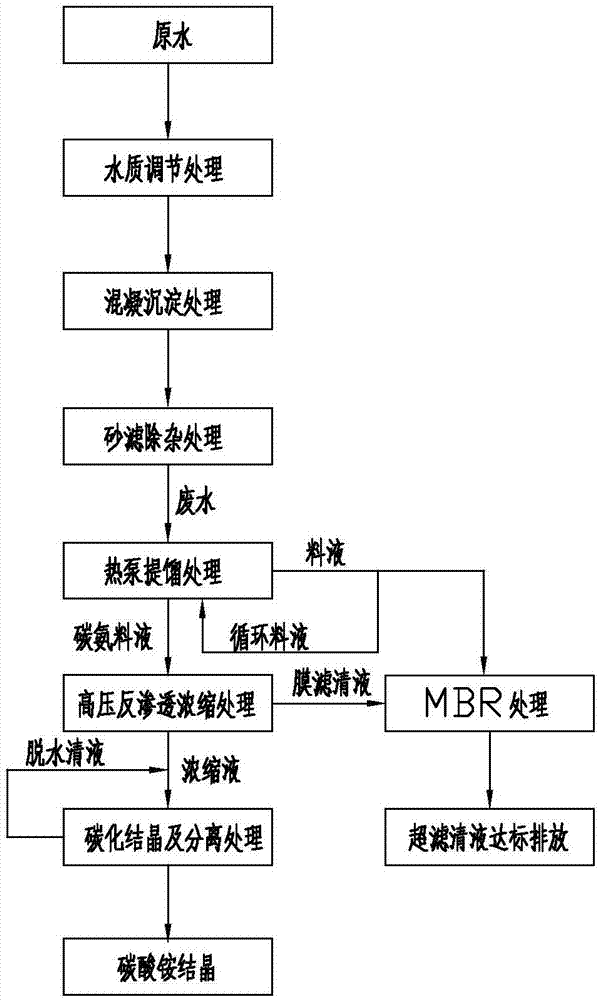

[0032] See figure 1 Shown, the processing method of a kind of high ammonia nitrogen waste water of the present invention, carries out according to the following steps.

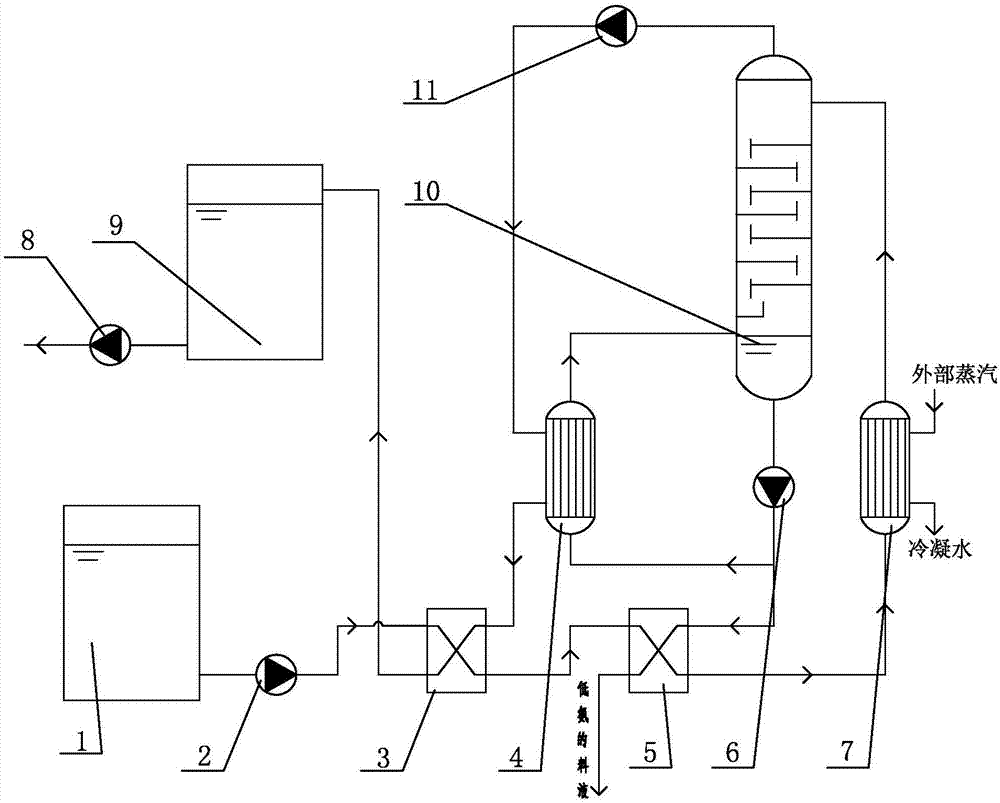

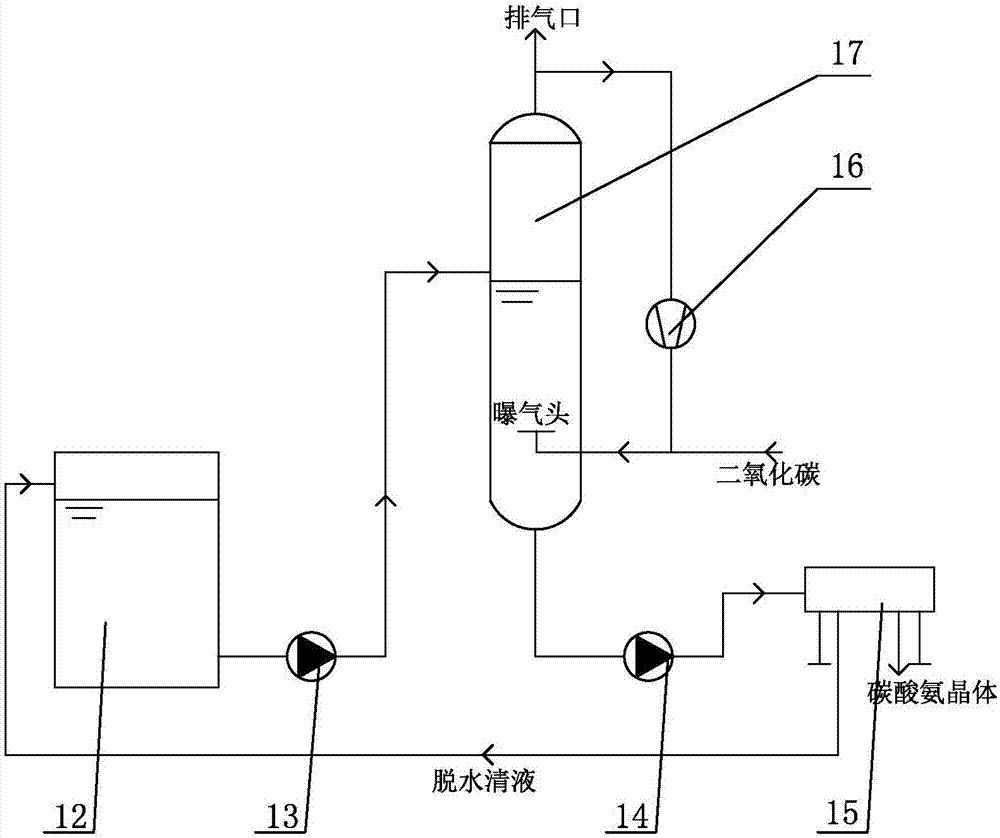

[0033] (1) Water quality adjustment treatment: send the raw water containing high ammonia nitrogen into the water quality adjustment tank, add carbonate and stir evenly, in order to improve the alkalinity of the raw water, the present invention controls the ratio of carbonate and ammonia nitrogen in the raw water to n( CO 3 2- ):n(NH 4 + -N)=1:1~3, if the ratio is controlled at 1:1.25~2.5, by adjusting and controlling the ratio of carbonate and ammonia nitrogen in the raw water, it can ensure sufficient alkalinity to participate in the subsequent deamination reaction wastewater Most of the ammonia nitrogen exists in the form of ammonium carbonate and ammonium bicarbonate, and the hardness ions in the raw water will continue to react with carbonate to form precipitates to reduce the risk of scaling in subse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com