Method for treating spent etching solution and treating equipment thereof

A technology of etching waste liquid and acidic etching waste liquid, which is applied in chemical instruments and methods, ammonia preparation/separation, water/sewage multi-stage treatment, etc., can solve the problems of waste, expensive use, environmental pollution, etc., and achieve recycling Reusable, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to a preferred embodiment of the present invention, the method further includes collecting ammonia gas and passing it into water, and passing through carbon dioxide to prepare ammonium bicarbonate.

[0038] According to a preferred embodiment of the present invention, sulfuric acid is added to the copper-containing precipitate to prepare a copper sulfate solution, which is crystallized to prepare CuSO 4 ·5H 2 O crystals.

[0039] According to a preferred embodiment of the present invention, the flocculant can be reused multiple times, preferably 5 times.

[0040] According to a preferred embodiment of the present invention, the flocculated flocs are separated by filtration or centrifugation.

[0041] According to a preferred embodiment of the present invention, the COD of the flocculated etching waste liquid is reduced to below 40 mg / L, and the arsenic content is reduced to below 0.8 ppm.

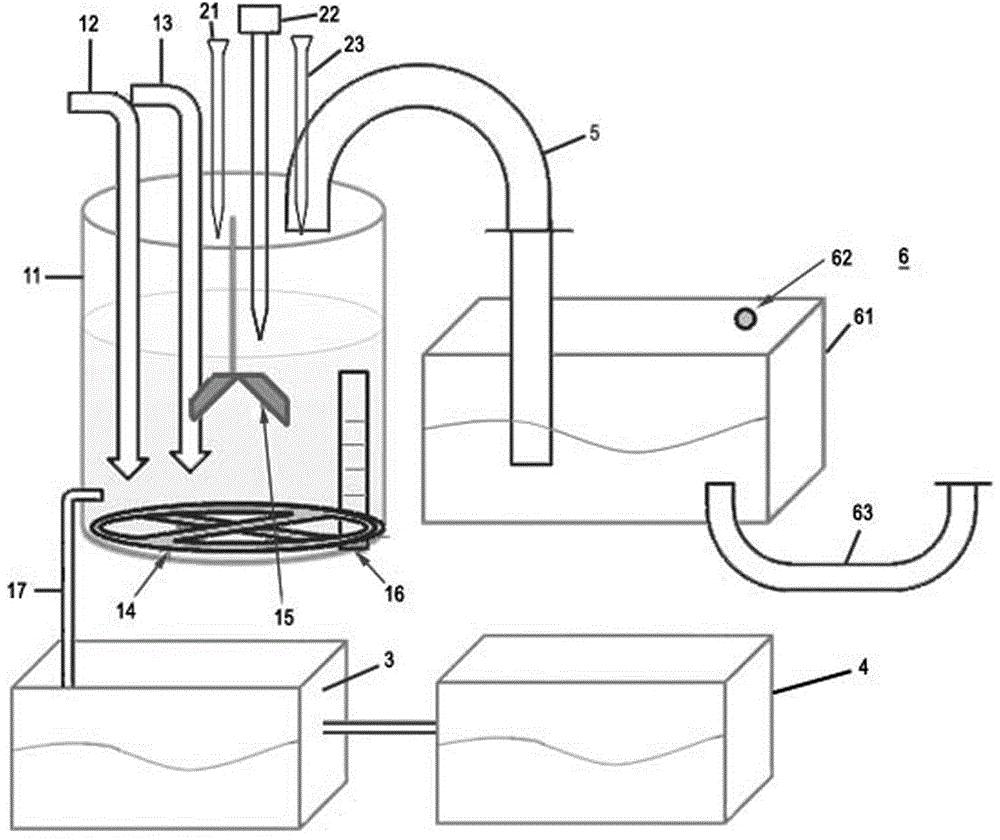

[0042] According to one aspect of the present invention, there is p...

Embodiment 1

[0061] 1000L of acidic etching waste liquid from the acidic etching workshop of Founder Group Gaomi Electronics Co., Ltd. (wherein the acidic etching waste liquid contains 140g / L of Cu 2+ , 2.0mol / L hydrochloric acid, 4000mg / L COD and 15ppm arsenic, and the pH is about 1.0) added to 500L alkaline etching waste liquid from the alkaline etching workshop of Founder Group Gaomi Electronics Co., Ltd. (alkaline etching Liquid contains 130g / L Cu 2+ , 10mol / L ammonium ion, 3800mg / L COD and 15ppm arsenic, where the pH is about 8.8). The volume ratio of acidic etching waste liquid to alkaline etching waste liquid is 2:1. The pH value of the mixed etching waste solution was adjusted to 7.5 with 1 mol / L soda ash solution, and heated to 95° C. for 2 hours to react. The released ammonia gas (approximately 4.78kM) was collected, and a 3.2kM CuO precipitate and filtrate were obtained by centrifugation.

[0062] Pass the collected ammonia gas into water and then into CO 2 , to prepare the ...

Embodiment 2

[0067] With the acidic etching waste liquid 1000L (wherein this acidic etching waste liquid contains the Cu of 145g / L) from the acidic etching workshop of Founder Group Multilayer Circuit Board Company 2+ , 2.0mol / L hydrochloric acid, 4500mg / L COD and 15ppm arsenic, and the pH value is 1.0) was added to 1000L alkaline etching waste liquid from the alkaline etching workshop of Founder Group Multilayer Circuit Board Company (where the alkaline Etching waste liquid contains 125g / L Cu 2+ , 10mol / L of ammonium ions, 4000mg / L of COD and 15ppm of arsenic, where the pH is 8.8). The volume ratio of acidic etching waste liquid to alkaline etching waste liquid is 1:1. The pH value is adjusted to 12-13 with NaOH particles, and the mixed etching waste solution is heated to a temperature of 100°C. Collect the released ammonia gas (about 9.6kM), and obtain Cu(OH)-containing 2 And CuO precipitate (copper-containing 4.2kM) and filtrate.

[0068] Pass ammonia gas into water and then gas CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com