Integrated utilization method of low grade magnesite

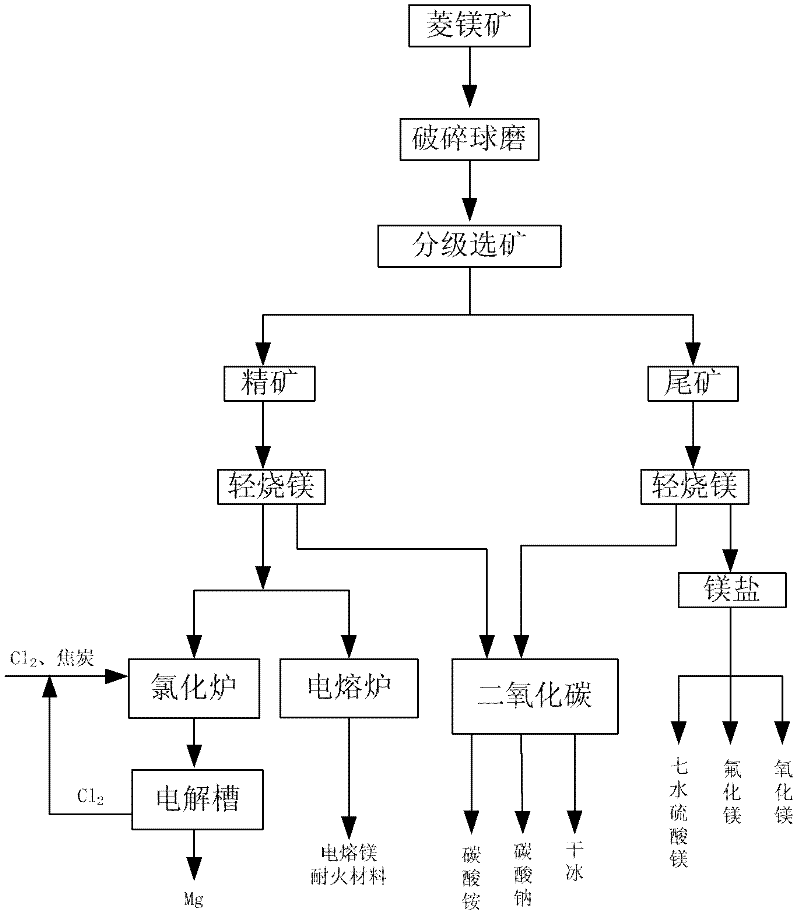

A magnesite, low-grade technology, applied in chemical instruments and methods, magnesium oxide, wet separation, etc., can solve the problems of difficult control of roasting time, low product purity, low output value, etc. The effect of high product purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

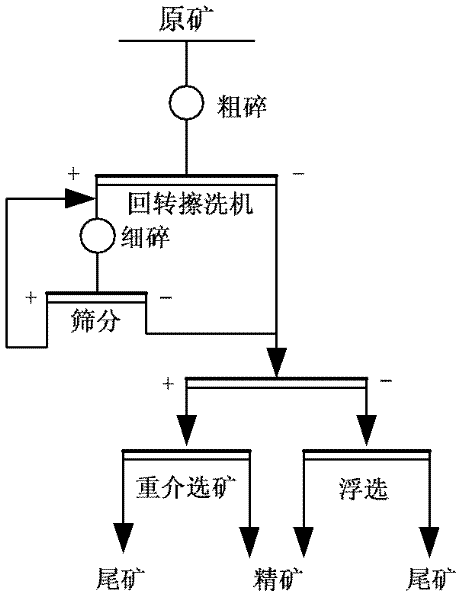

[0025] Example 1: A magnesite test ore sample was crushed to -1 mm by a hammer crusher, and then ground by a ceramic ball mill to -200 mesh, accounting for about 85%, and then the flotation test was carried out. The flotation test was carried out in a 1.5L XFD type hanging tank flotation machine. The medicaments used are dodecylamine, sodium carbonate, water glass, and sodium hexametaphosphate, which are analytically pure. The flotation process and reagent system such as image 3 :

[0026] The test results are as follows:

[0027]

[0028] A horizontal fluidized bed is used to lightly burn the flotation tailings, the temperature is controlled at 950°C, and the time is 0.5h. Take 30 g of the lightly burned product, add 40 mL of 10% HCl to react for 25 minutes, and then filter. The filtrate is adjusted to pH 4.5 with freshly digested milk of lime and filtered to obtain a pure filtrate. Fresh milk of lime was added to the purified filtrate at a rate of 10 mL / min, and the ...

Embodiment 2

[0031] Example 2: A high-silicon and low-grade magnesite was desiliconized by a heavy-floating combined process, and the chemical multi-element analysis results of the raw ore are as follows:

[0032] element MgO SiO 2 CaO Fe 2 o 3 Burn out content 42.95 6.08 1.15 0.29 48.27

[0033] use Figure 4 The mineral processing method shown is to process the ore sample:

[0034]After coarse crushing, the ore is graded by a rotary scrubbing machine, and the coarse particles are crushed and screened again; the fine particles are washed again, the products under the screen are flotation, and the products on the screen are subjected to heavy-medium beneficiation in a cyclone, and the flotation concentrate and the dense-medium concentrate Combined into final concentrate. The final concentrate recovery and grade were 70.33% and 46.82% respectively.

[0035] The obtained tailings were lightly burned by using a horizontal fluidized bed at a controlled ...

Embodiment 3

[0037] Example 3: The raw ore ground in Example 1 was first magnetically separated in a magnetic separation tube with a magnetic field strength of 1400oe, and then flotation operation was performed to obtain an iron concentrate with a yield of 0.57% and a total iron grade of 52.12% At the same time, the concentrate ferric oxide in the flotation products dropped from 0.31% to 0.24%.

[0038] Lightly burn the flotation tailings with a horizontal fluidized bed at a controlled temperature of 750°C for 50 minutes. Take lightly burned product 30g, add 10% H 2 SO 4 40 mL was reacted for 30 minutes and filtered, and the filtrate was adjusted to pH 3.0 with ammonia water to remove iron, and NaS was added to remove heavy metals, then evaporated and crystallized to obtain MgSO 4 ·7H 2 O.

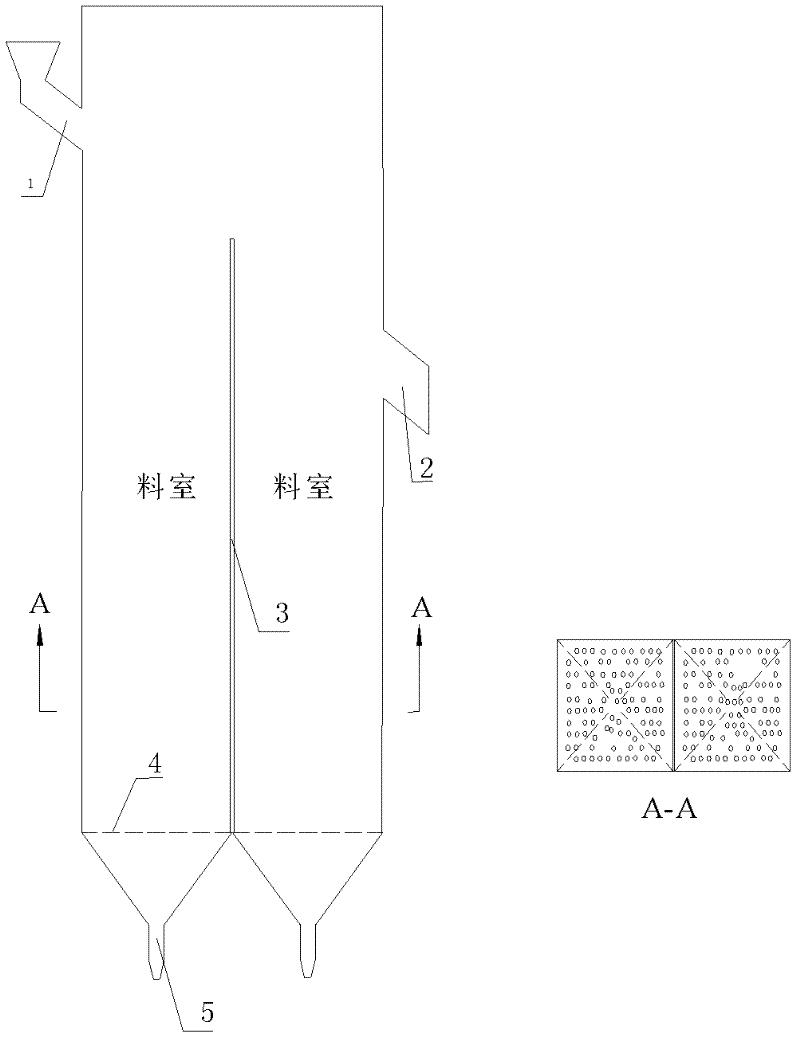

[0039] Take 130g of the light-burned product obtained from the flotation concentrate in a horizontal fluidized bed at a temperature of 1000°C and a time of 20 minutes, with a carbon blending coeffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com