Red mud magnetizing roasting comprehensive utilization system and technology

A technology of magnetized roasting and red mud, which is applied in the comprehensive utilization system and process field of magnetized roasting of red mud, which can solve the problems of waste, low efficiency of fine iron ore, and difficult control of various reactions in reduction, so as to achieve rapid response and improve iron grade , Improve the effect of comprehensive utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

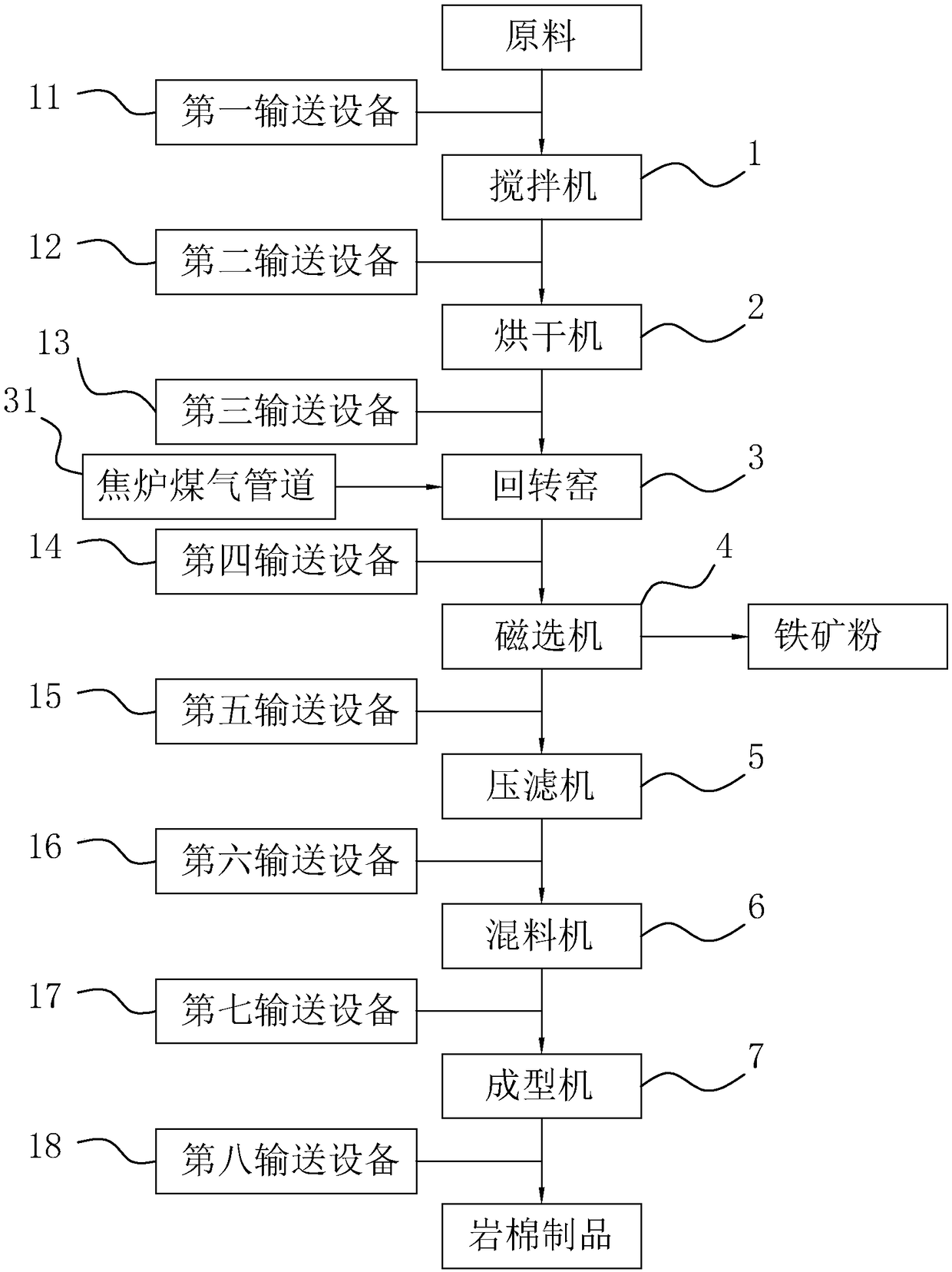

[0055] Embodiment 1: A comprehensive utilization system of red mud magnetization roasting, such as figure 1 and figure 2 As shown, it includes a mixer 1, a dryer 2, a rotary kiln 3, a magnetic separator 4, and a filter press 5, and the rotary kiln 3 is provided with a coke oven gas pipeline 31.

[0056] The mixer 1 is provided with a material inlet and a material outlet. The material inlet of the mixer 1 is connected to a first conveying device 11 , and the other end of the first conveying device 11 is connected to a red mud stockpiling area. Mixer 1 can use the DCS control high-viscosity material mixer produced by Jiuye Sanwei Chemical Machinery, which is suitable for mixing red mud with viscosity to make the material fully mixed. The first conveying device 11 may be a belt conveyor, and the red mud is transported to the mixer 1 through the first conveying device 11 . An additive funnel is provided at the feed port of the mixer 1, and pre-prepared additives are placed in t...

Embodiment 2

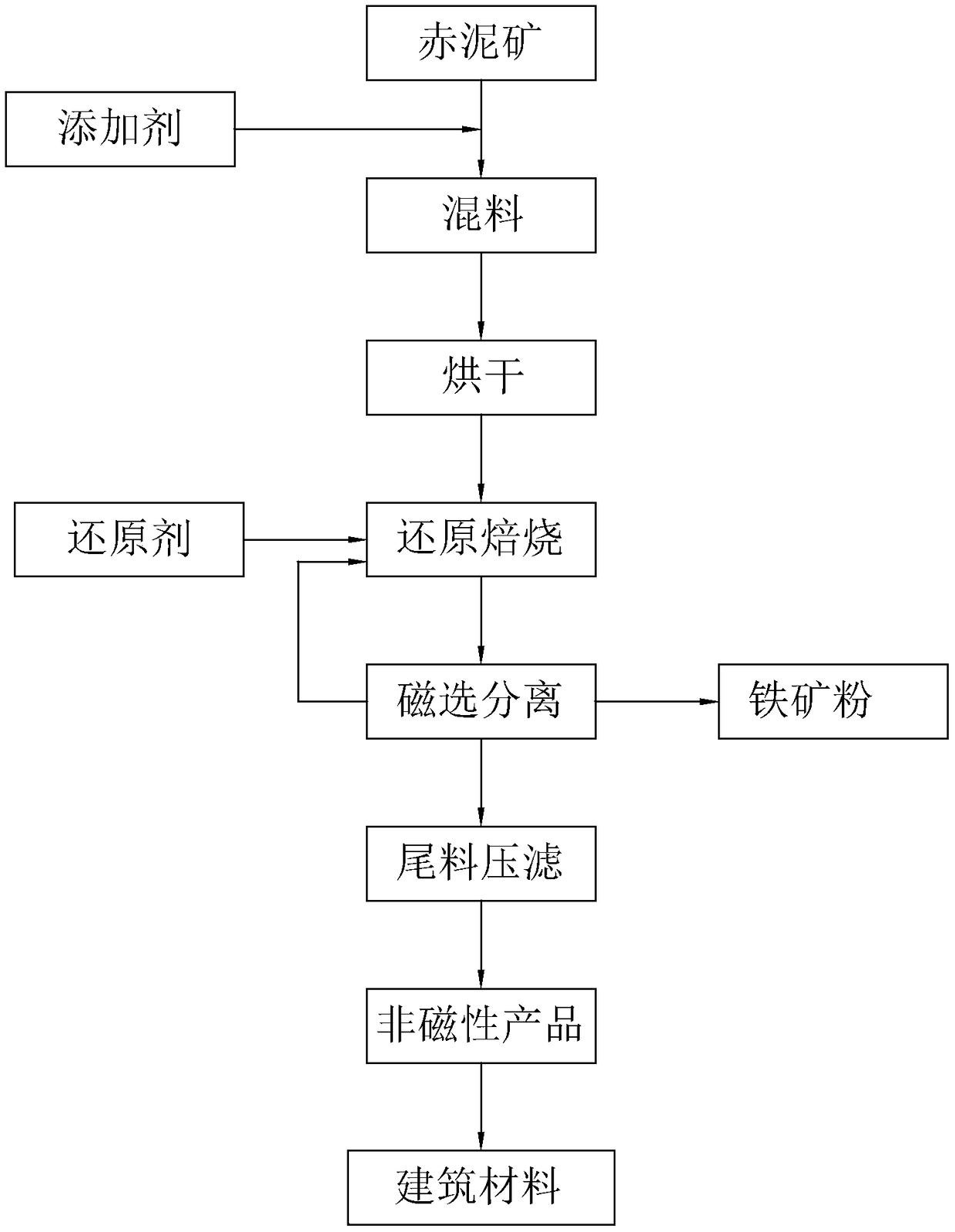

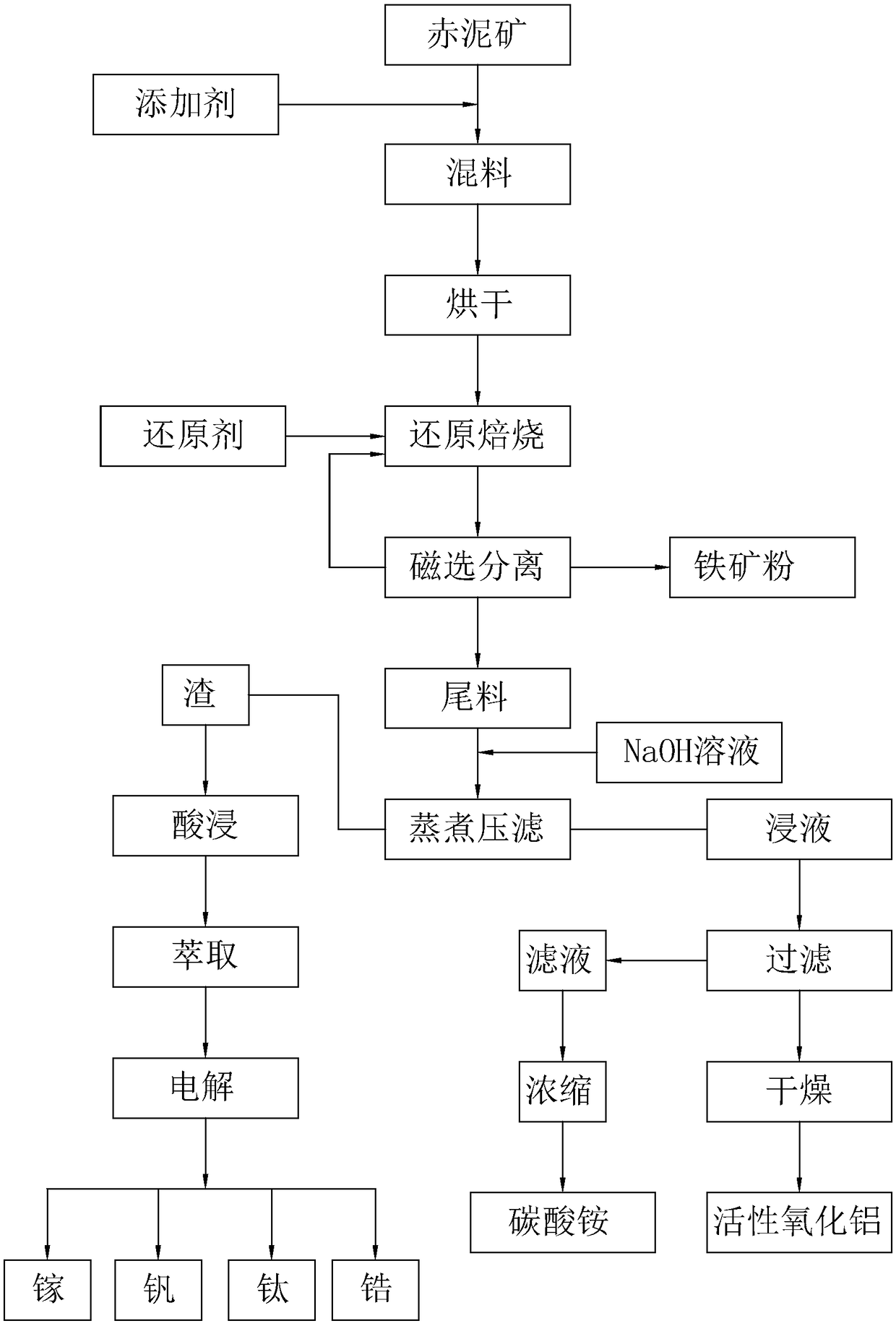

[0088] Example 2: A comprehensive utilization process of red mud magnetization roasting, such as image 3 As shown, the difference from Example 1 is that the non-magnetic tailings after magnetic separation are subjected to cooking and pressure filtration treatment.

[0089] Mix the non-magnetic tailings with an excess of 1.3-1.5% of the oxidant sodium persulfate based on the silicon content of the slag. The functions of sodium persulfate are as follows: First, its oxidation prevents silicon from becoming low-priced and easy-to-gel SiO 3 2- , and become SiO with high price and not easy to gel 4 2- , the second is to provide Na + , making silicon a macromolecular Na that is not easy to gel 2 SiO 4 , easy to filter and separate. Then put the mixed material into a heatable reaction kettle, add sodium hydroxide solution in the reaction kettle and carry out microboiling cooking for 1-2h, so that the aluminum is Na 2 AlO 2 Dissolution, oxidation of silicon into non-colloidal ...

Embodiment 3

[0098] Embodiment 3: A red mud magnetization roasting comprehensive utilization process. The difference from Embodiment 1 is that the iron fine powder separated by the magnetic separator is further subjected to reverse flotation to remove impurities and improve the grade of the iron fine powder. Specific steps are as follows:

[0099] (1) The iron ore powder is ultra-finely ground in a ball mill to an average fineness of 250 mesh, of which 250-300 mesh accounts for more than 90% of the total.

[0100] (2) Put the ultra-fine iron ore powder into the flotation tank, add water and stir to form a slurry, so that the ultra-fine iron ore powder is suspended in the solution. The average concentration of the iron ore powder in the solution is 30g / L, and the water temperature is controlled At 40°C, add DBU to adjust the pH value of the slurry to 11, and the stirring speed is 1200r / min.

[0101] (3) Add flotation agent to the solution, the mass ratio of flotation agent to iron ore powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com