Comprehensive treatment method for carrying out desulfurization, denitration, mercury removal and recycling on flue gas of boiler

A technology for desulfurization and denitrification, boiler flue gas, applied in the direction of chemical instruments and methods, separation methods, ammonium sulfate, etc., can solve the problems of easy to block equipment, high operating costs, post-treatment and cost of resistance loss, etc., to achieve applicable Wide range and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

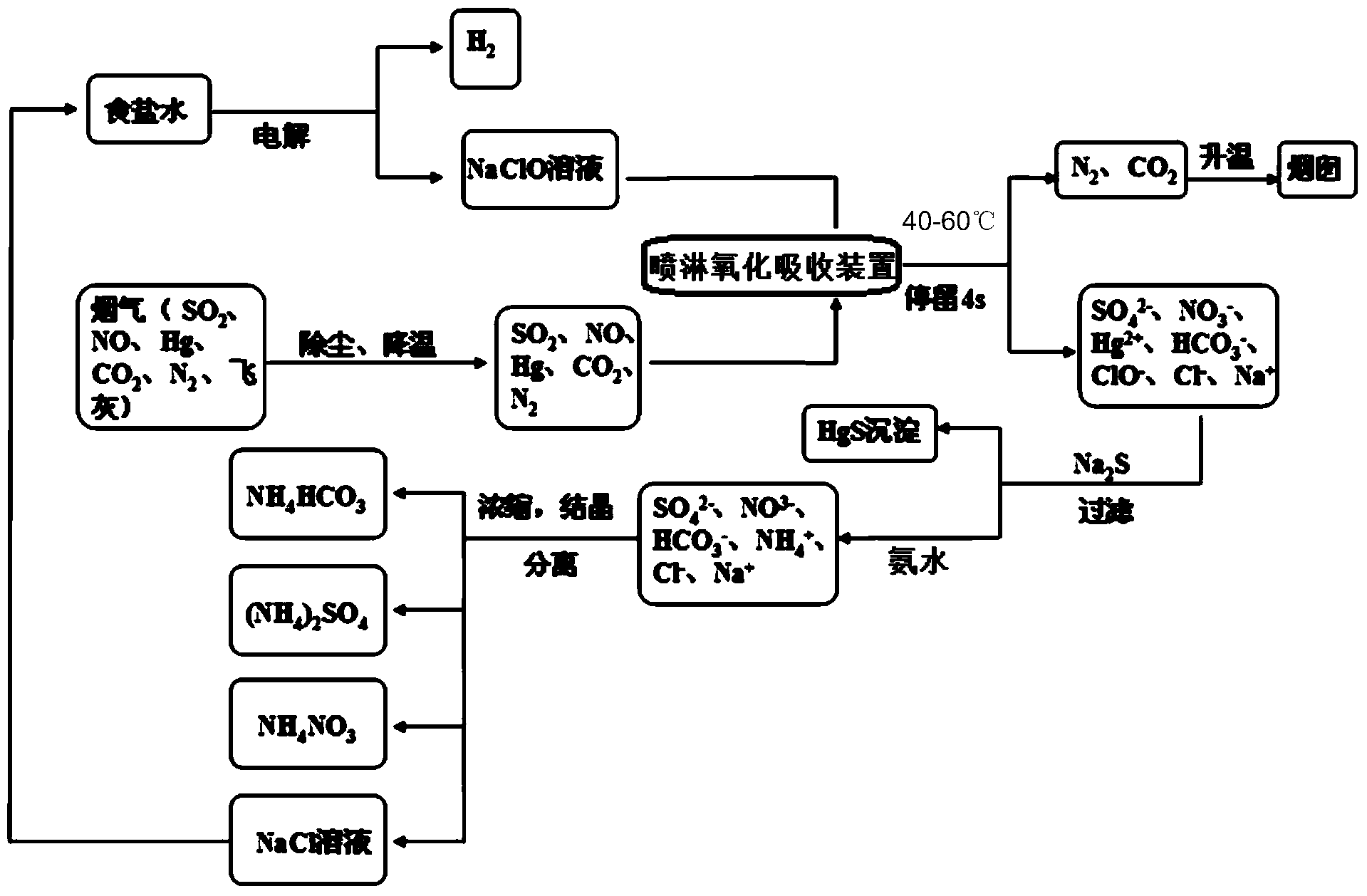

[0033] a. Preparation of oxidation absorbent: send purified salt water into sodium hypochlorite generator for electrolysis to obtain sodium hypochlorite solution and H 2 , wherein sodium hypochlorite solution is used as an oxidation absorbent. In step a, sodium hypochlorite solutions of different concentrations are obtained by controlling conditions such as electrolysis temperature, sodium chloride concentration, solution pH, electrode area, and current density. As an oxidation absorbent, the concentration of sodium hypochlorite solution is controlled at 0.9-3.5g / L. In step a, the brine used for electrolysis to generate sodium hypochlorite solution can also be obtained by purifying and refining waste brine from power plants.

[0034] b. Oxidative absorption of pollutants in flue gas: pump the sodium hypochlorite solution obtained in step a from the top of the spray oxidation absorption device, and form convection with the incoming flue gas, so that the CO in the flue gas 2 Ab...

Embodiment 1

[0047] Step 1: Send purified 15g / L salt water at 20°C into the sodium hypochlorite generator at a flow rate of 5L / h, at 15A / dm 2 A 1.5g / L sodium hypochlorite solution was obtained at a current density of 1.5 g / L as an oxidation absorber.

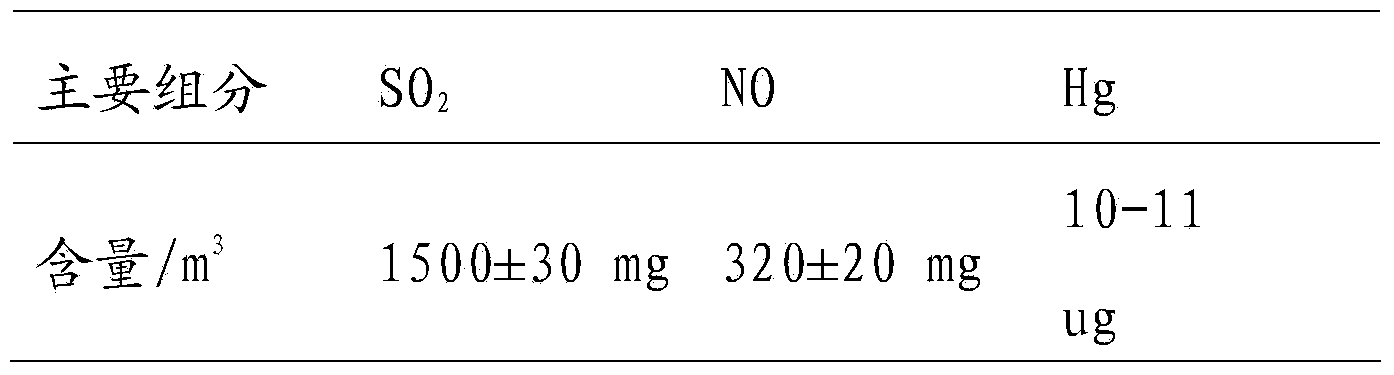

[0048] Step 2: The sodium hypochlorite solution of 1.5g / L obtained in step 1 is pumped in from the top of the spray oxidation absorption device, forms convection with the flue gas shown in Table 1 that passes through, controls the liquid-gas ratio to be 8, and the gas flow rate is 5m / s, the flue gas purification temperature is 40°C. The purified gas is discharged from the upper end of the tower, almost 100% SO 2 was removed, NO x The removal rate is 92%, CO 2 The removal rate of Hg is close to 5%, and the removal rate of Hg is close to 100%; the sprayed mixed oxidation absorption solution contains SO 4 2- , NO 3 - 、HCO 3- , Cl - 、Na + , Hg 2+ .

[0049] Step 3: Add 0.01M Na to the oxidation absorption solution obtained in step 2...

Embodiment 2

[0053] Control the flue gas purification temperature to 45°C, other operations are the same as in Example 1, and almost all SO can be removed 2 and mercury, NO x The removal rate reaches more than 90%, CO 2 The removal rate is close to 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com