Automatic treatment system for waste acid liquid generated after metal pickling and process thereof

A treatment system and waste acid technology, applied in metallurgical wastewater treatment, special treatment targets, water/sewage treatment, etc., can solve problems such as high operation and maintenance costs, secondary pollution, and secondary pollution from waste residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

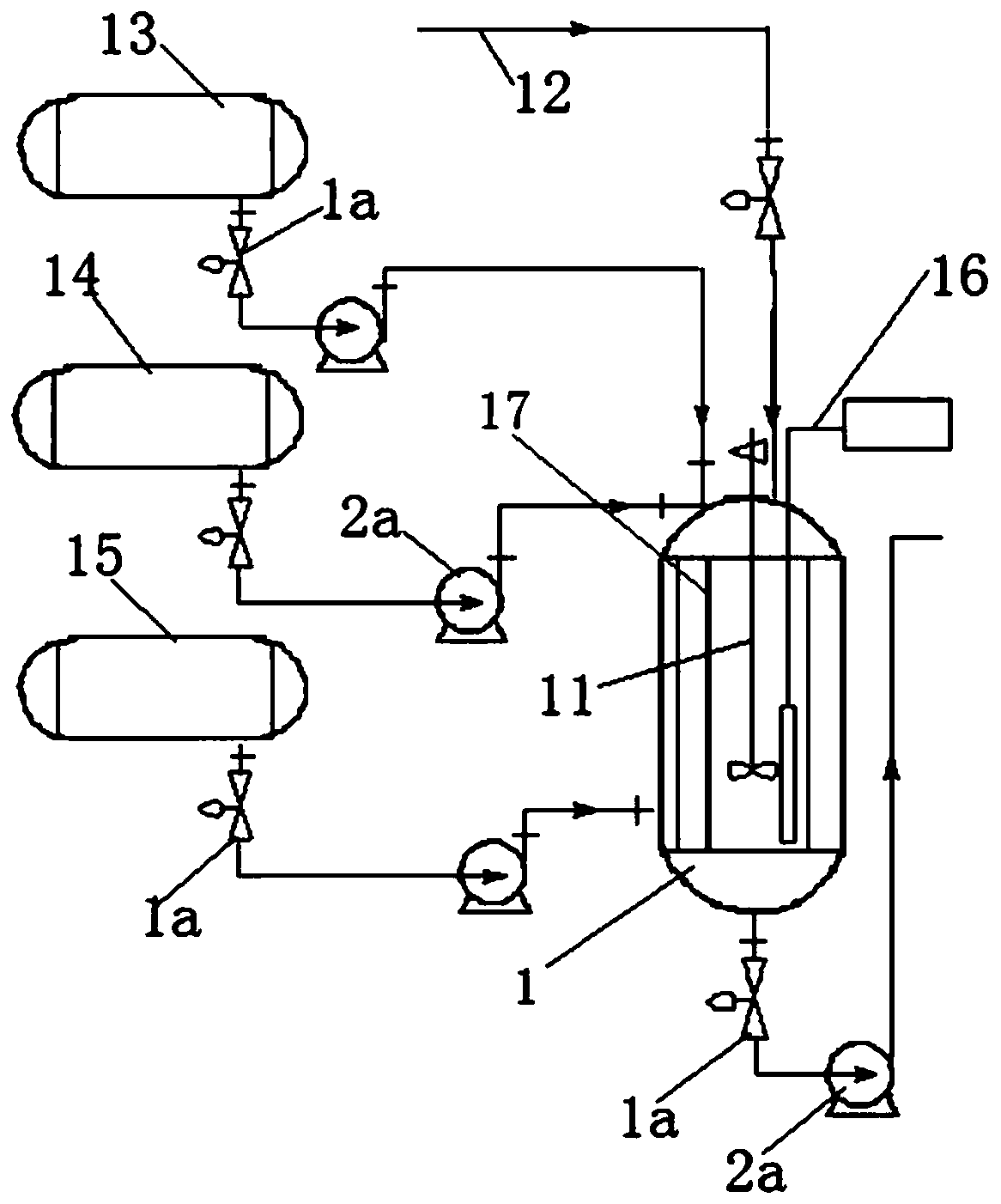

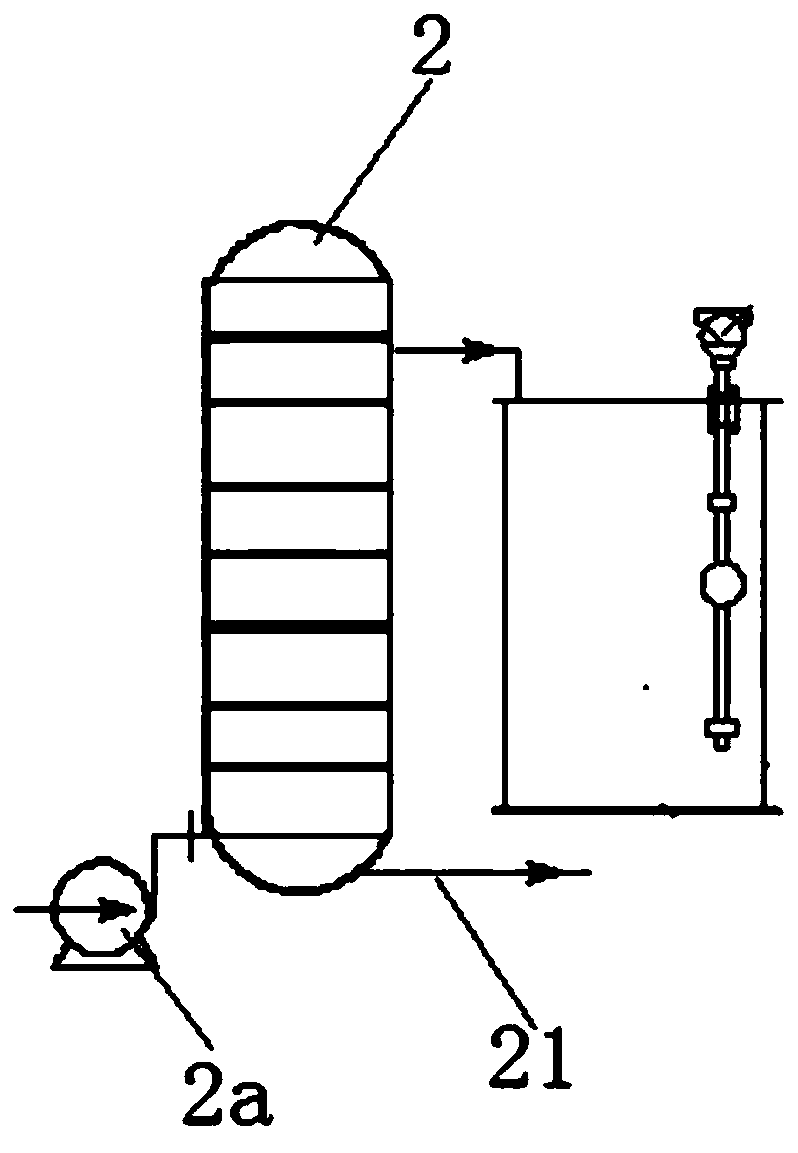

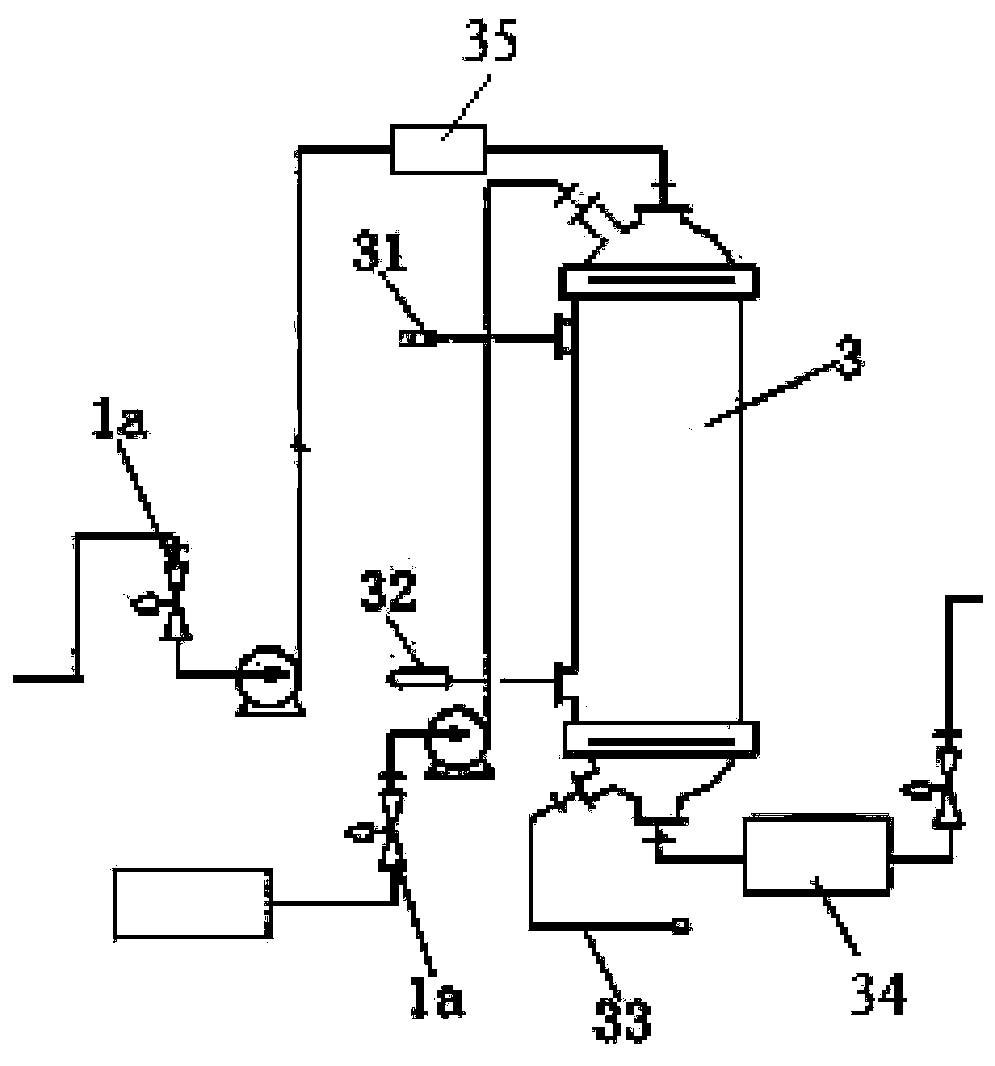

[0049] Such as Figure 1-5 As shown, this embodiment provides an automated processing system for producing waste acid after metal pickling, including:

[0050] Oxidation reaction system, such as figure 1 As shown, it includes an oxidation tank 1 provided with a waste liquid input pipe 12, and a stirrer 11 is provided in the oxidation tank 1; the stirrer 11 is connected to the controller; and it also includes a first additive for delivering treatment chemicals to the oxidation tank 1. The connecting pipes between the first dosing tank 15, the second dosing tank 14, and the third dosing tank 13 and the oxidation tank 1 are all set There are electromagnetic control valve 1a and conveying power pump 2a; the liquid medicine in the first dosing tank 15 is oxidant, the liquid medicine in the second dosing tank 14 and the third dosing tank 13 is lye; the system mainly uses data The pH meter in the intelligent control system detects the pH value of the waste acid in the oxidation tank on...

Embodiment 2

[0057] This embodiment provides an automated treatment process for the waste acid produced after metal pickling, which is based on the automated treatment system of embodiment 1, and specifically includes the following steps:

[0058] (1) Input the critical value of each system startup: input the relevant procedures for the treatment of waste acid liquid and the relevant data of the online detection of each system processing into the digital programming control system, and use the online detection value of each system to control the operation of the equipment ; Specifically: a. The first level gauge 17 installed in the oxidation tank 1, when the waste acid level reaches 1 / 2 of the volume of the oxidation tank 1, stop injecting the waste acid; installed in the reaction of the purification regeneration system The second level gauge of the osmosis unit 5, when the volume of pure water enters the reverse osmosis unit 5 times reaches 1 / 2 of the container volume, the reverse osmosis mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com