Apparatus and method for hydrogen generation

A technology for generating devices and hydrocarbons, which is applied in hydrogen/syngas production, chemical instruments and methods, hydrogen, etc., and can solve the problems of complex heat resistance or durability, increased equipment cost, poor thermal efficiency, etc. The effect of simple thermal or durability, reduced equipment cost, high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

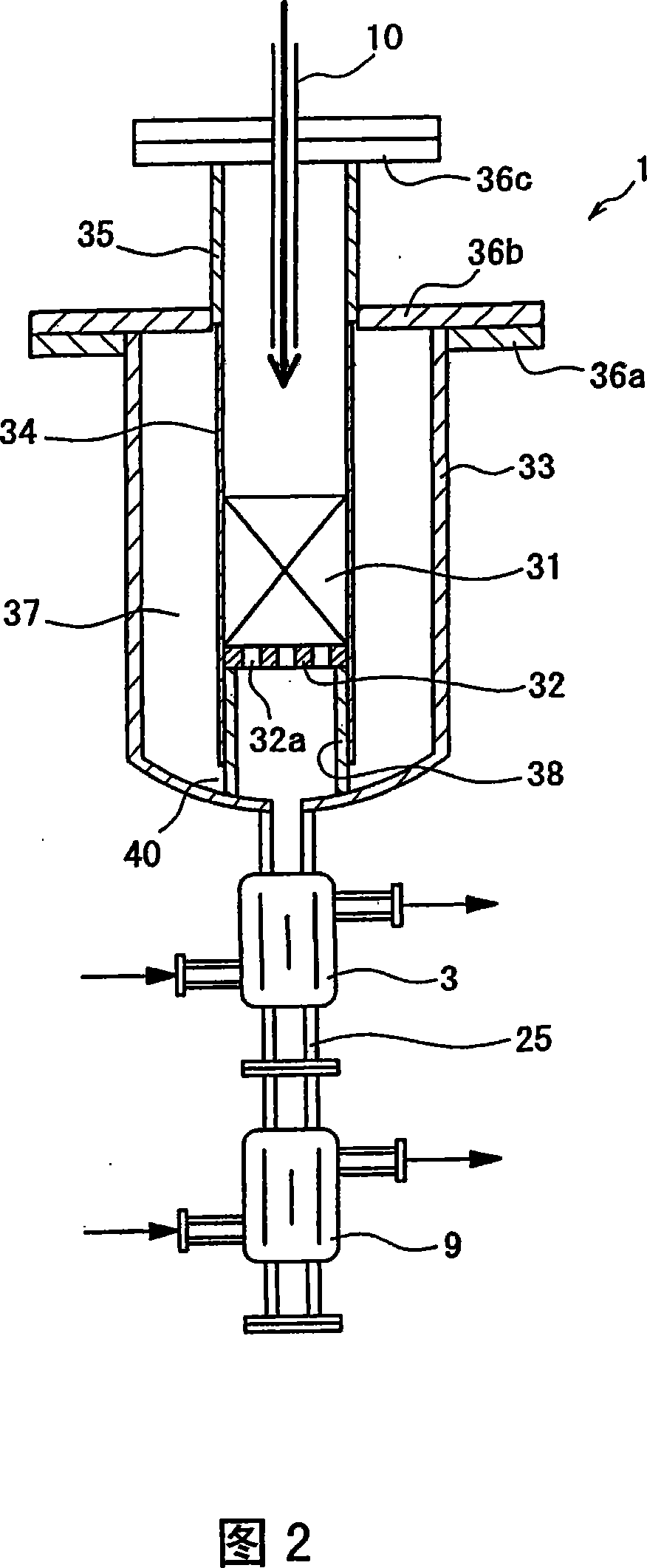

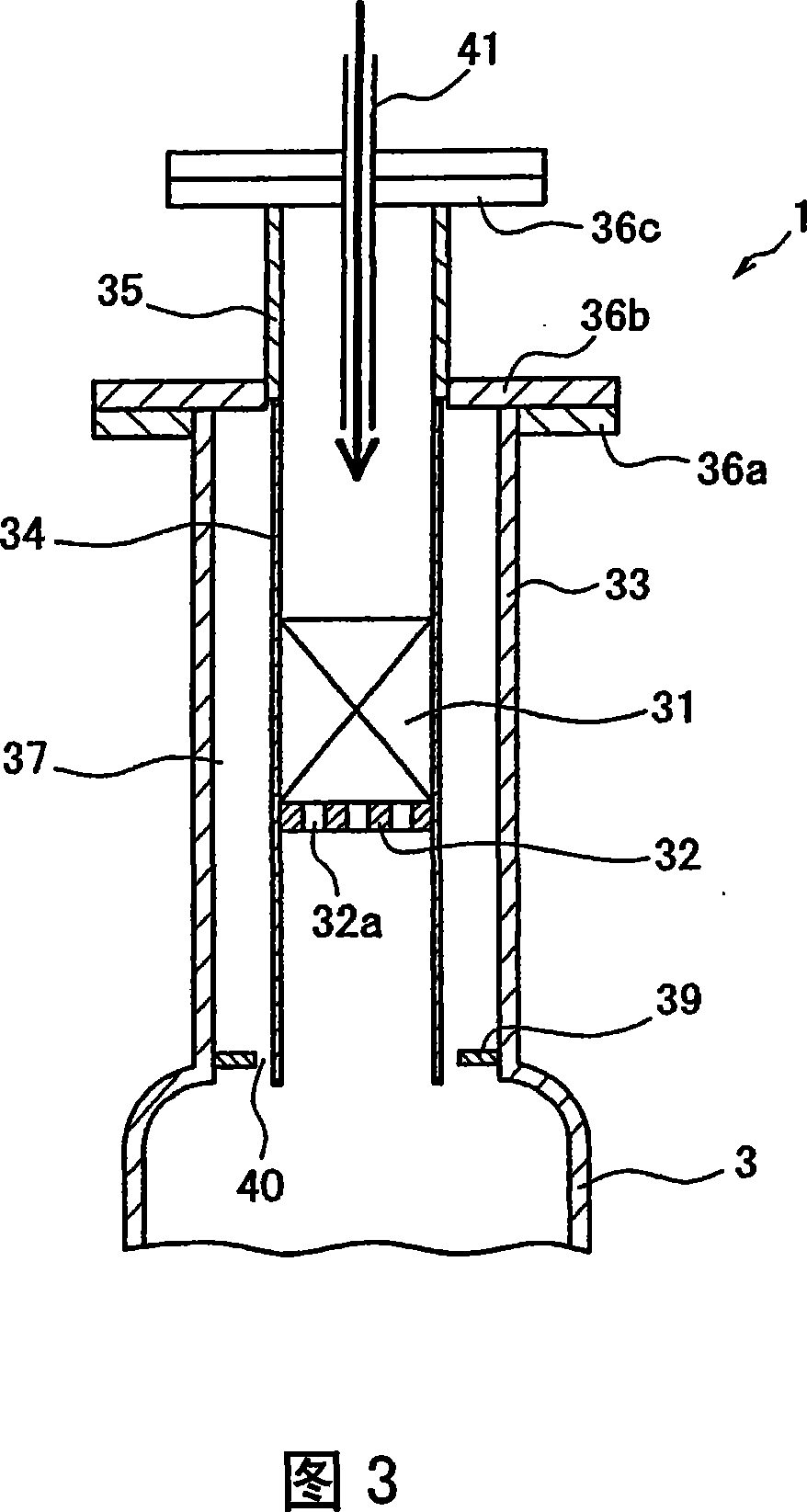

[0020] Next, the best mode for implementing the present invention will be described.

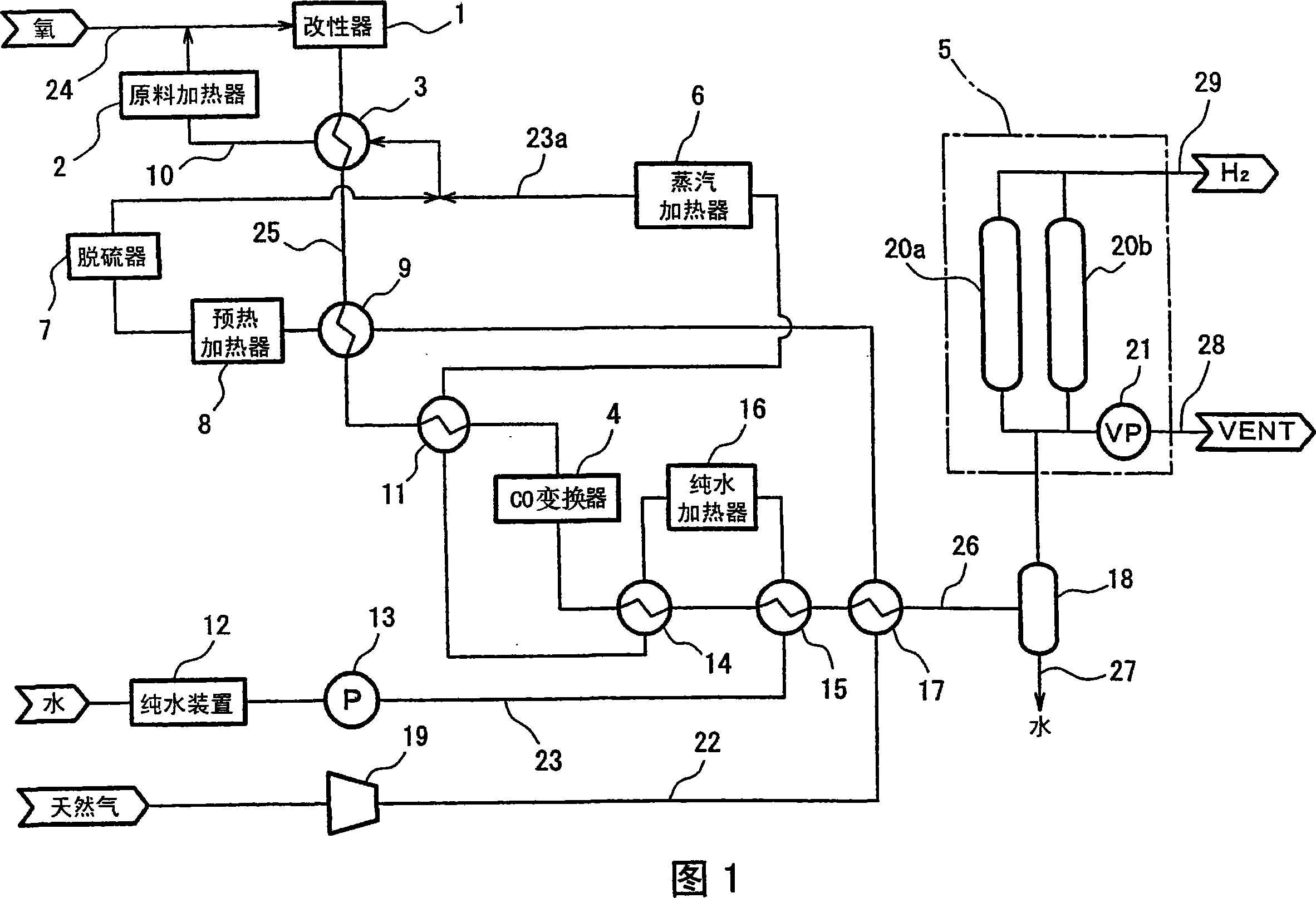

[0021] FIG. 1 is a configuration diagram showing an example of a hydrogen generator to which the present invention is applied.

[0022] This hydrogen generator is a hydrogen generator that reforms a hydrocarbon-based gas to generate a reformed gas rich in hydrogen. As the raw material gas, hydrocarbon-based gases such as natural gas and biogas, including hydrocarbon-based gases supplied as social infrastructure such as propane gas and city gas, can be used. In the following description, natural gas is used as the hydrocarbon-based gas as an example.

[0023] This hydrogen generator includes: a reformer 1 that introduces natural gas, water vapor, and oxygen as raw material gases and reforms the natural gas; a CO shifter 4 that converts the reformed gas discharged from the reformer 1 into CO; Adsorption device 5 for impurities in the reformed gas after CO shift.

[0024] In addition, the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com