Metal gravity casting mould and method

A technology of gravity casting and metal mould, which is applied in the field of metal type gravity casting mold and casting, and metal type gravity casting. It can solve the problems of large waste gas discharge of redundant structures and increased air permeability of sand cores, so as to achieve good compactness and improve utilization Efficiency and less exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

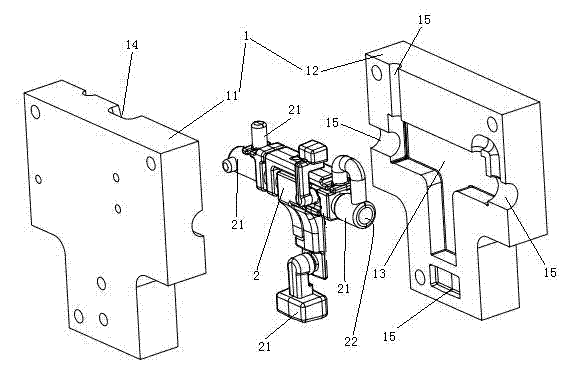

[0022] Embodiment one, see figure 1 , a metal gravity casting mold, comprising a metal mold 1 and an inner cavity sand core 2.

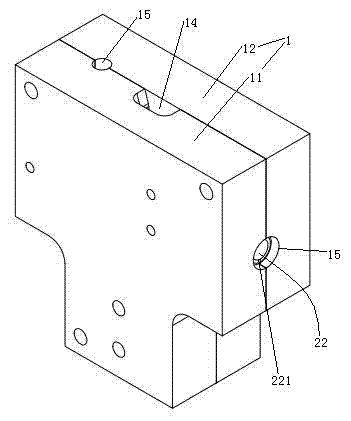

[0023] The metal mold 1 includes a first mold half 11 and a second mold half 12 . A cavity 13 is provided in the metal mold 1 . A pouring hole 14 and four positioning holes 15 are provided on the metal mold 1 . Three of the four positioning holes 15 are through holes. The pouring hole 14 and the positioning hole 15 are arranged on the connecting surface of the first half mold 11 and the second half mold 12 . Casting holes are only offered on the first half mold 11. The positioning hole 15 is surrounded by a half on the first mold half and a half on the second mold half.

[0024] The inner cavity sand core 2 is formed by molding sand bonded together by a bonding material. The cavity core 2 is provided with four connecting heads 21 . The cavity core 2 is provided with an exhaust channel 22 extending from the end surface of one of the four connec...

Embodiment 2

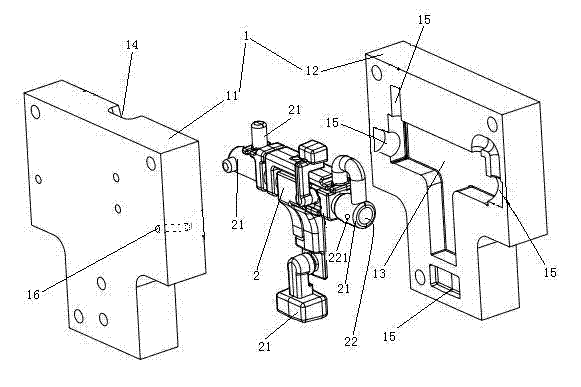

[0026] Embodiment two, see image 3 , the difference with the first embodiment is: all the positioning holes 15 do not pass through the metal mold 1, that is, they are not through holes. The outlet 221 of the exhaust channel is arranged on the side of the positioning head 21 . An air passage 16 communicating with the outer surface of the metal mold 1 and the outlet 221 of the exhaust passage is provided in the metal mold. During the casting process, the gas in the exhaust through hole 22 is discharged to the outside of the metal mold 1 through the air channel 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com