System and method for recycling water vapor during roasting aluminum hydroxide

A technology of aluminum hydroxide and water vapor, which is applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of increased alumina production cost, increased power consumption, waste of water resources, etc., to save electricity consumption and The effect of fuel consumption, reduction of exhaust gas, and promotion of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

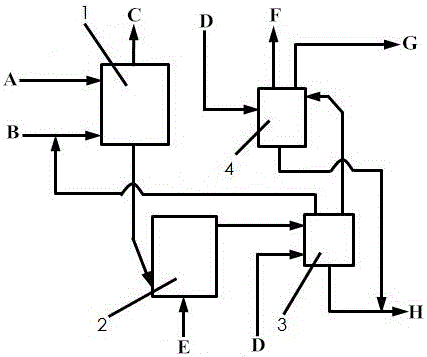

[0028] Below the embodiments of the present invention are combined with the attached figure 1 Described in detail, but the protection scope of the present invention is not limited by the examples.

[0029] Such as figure 1 As shown, the system for recovering water vapor by roasting aluminum hydroxide in this embodiment includes a water vapor recovery device 1, a main furnace 2, a suspension separation heat exchanger 3 and a heat exchange device 4;

[0030] The feed port of the steam recovery device 1 is communicated with the aluminum hydroxide feeding device, the discharge port of the steam recovery device 1 is connected with the feed port of the main furnace 2, and the discharge port of the main furnace 2 is separated from the suspension The feed port of the heat exchanger 3 is connected, the powder outlet of the suspension separation heat exchanger 3 is the discharge port, the gas outlet is connected with the air inlet of the heat exchange device 4, and the gas outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com