Mixing insulating gas dynamic gas distribution device

A technology of mixing insulating gas and dynamic gas distribution, applied in the field of power system, can solve the problem of high liquefaction temperature of high-insulation-strength gas, and achieve the effects of high mixing efficiency, reduction of waste gas volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

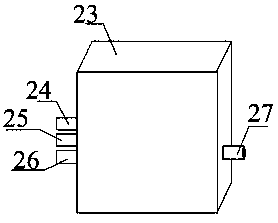

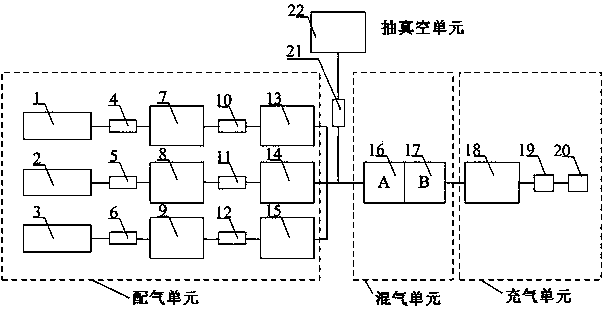

[0025] Please also refer to figure 1 with figure 2 As shown, the embodiment of the present invention provides a dynamic gas distribution device for mixed insulating gas, including:

[0026] protective casing;

[0027] an air distribution unit, an air mixing unit and an air charging unit arranged inside the protective housing;

[0028] The gas distribution unit includes at least one first gas distribution branch for distributing a first type of gas, and at least one second gas distribution branch for distributing a second type of gas. The dielectric strength of the first type of gas is and liquefaction temperature are higher than the second gas;

[0029] The gas mixing unit is connected to the gas distribution unit for mixing the first type of gas and the second type of gas;

[0030] The gas cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com