Mechanical stoker type destructor and refuse burning method

A technology of waste incinerator and motorized grate, which is applied in the combustion method, incinerator, combustion type, etc., can solve the problems of inability to suppress NOx and increase the amount of exhaust gas, and achieve the effect of reducing height and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

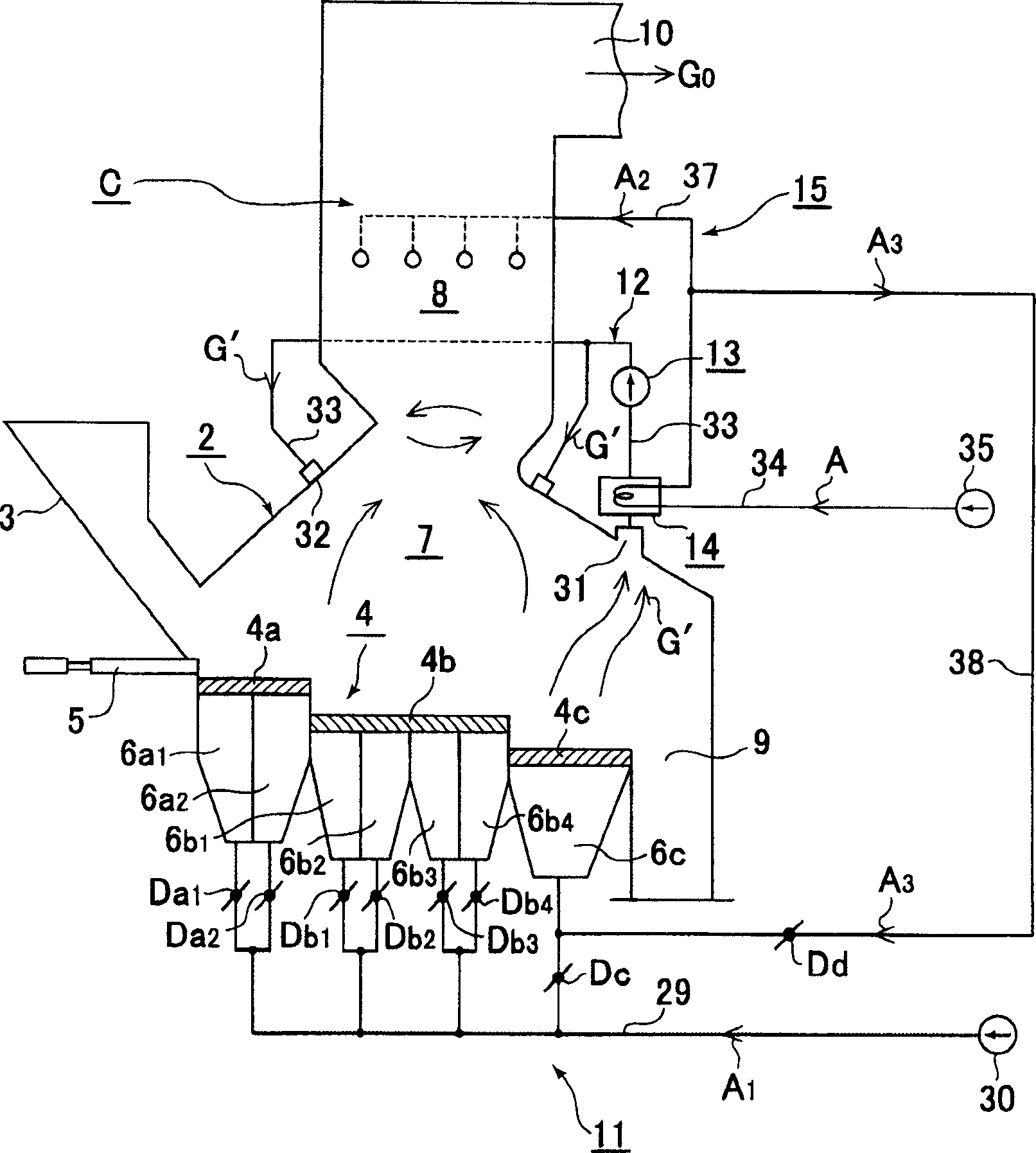

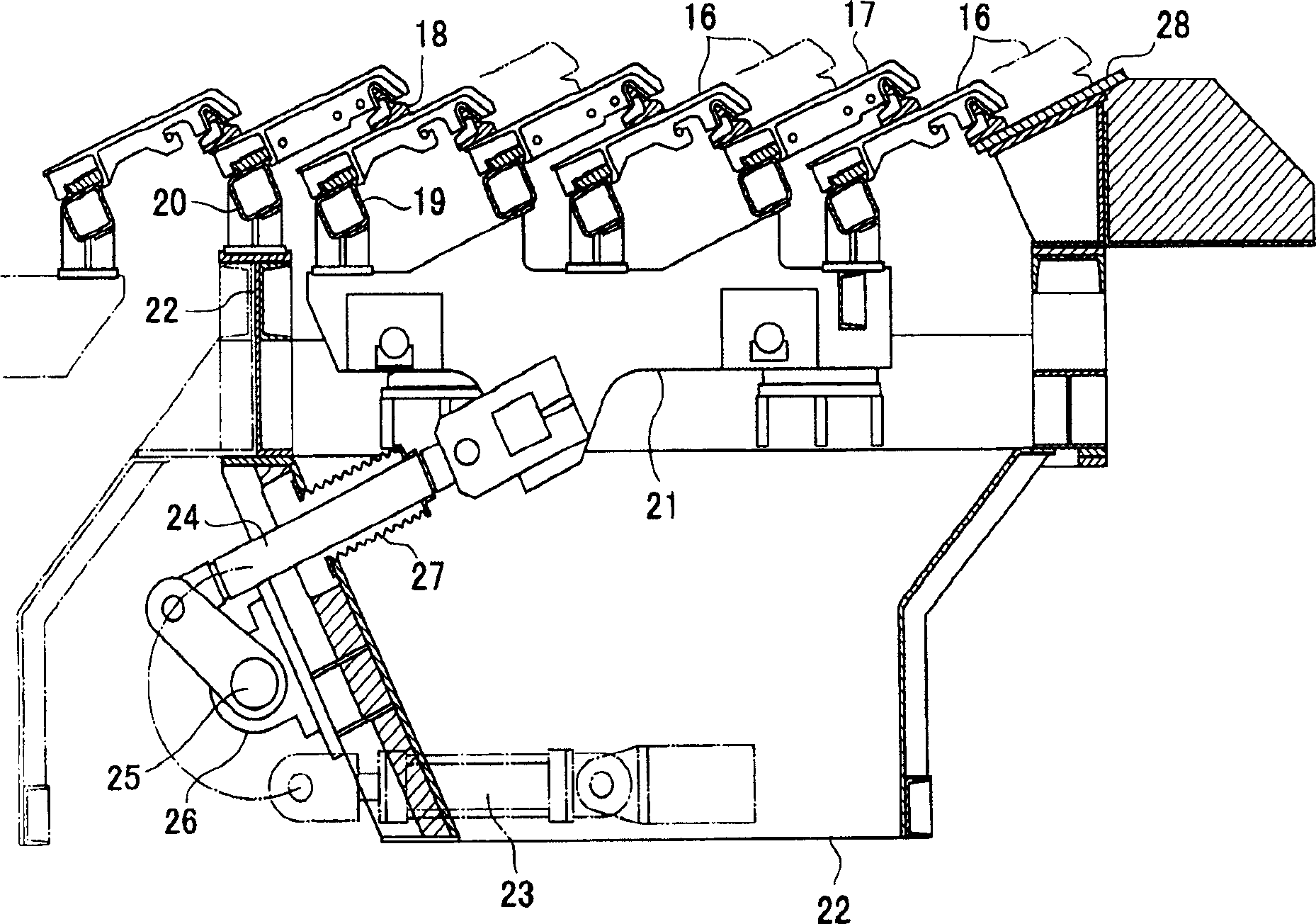

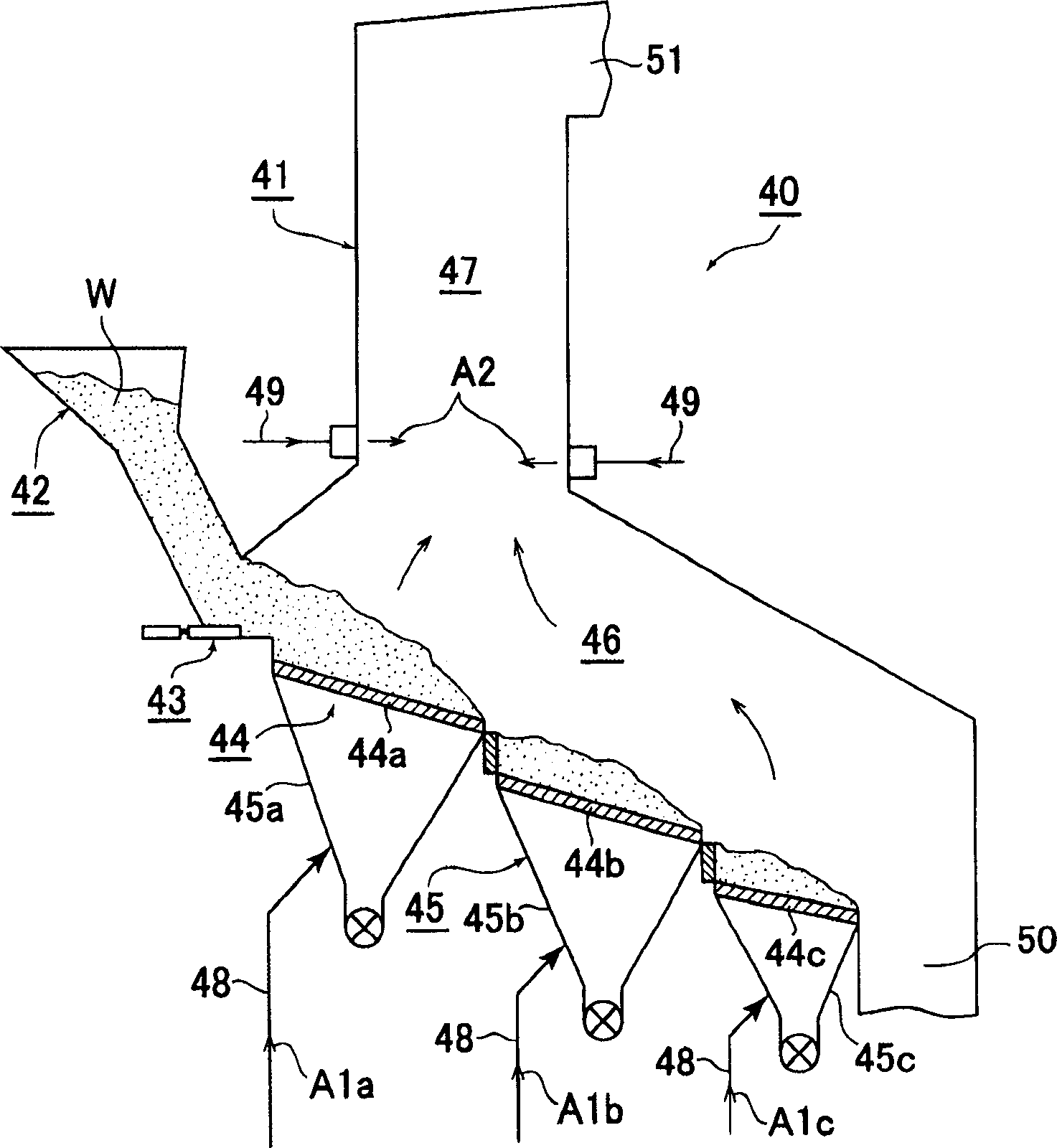

[0031] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0032] figure 1 Shown is an example of the motorized grate type refuse incinerator 1 of the present invention. This garbage incinerator 1 is made up of following parts: the furnace main body 2 that is made of furnace wall; The garbage funnel 3 that puts into municipal waste W usefulness; The motorized fire grate 4 that burns municipal waste W usefulness; Municipal waste W is delivered to motorized fire grate 4 The upper garbage supply device 5; the lower funnel 6 of the motorized grate arranged under the motorized grate 4; the primary combustion chamber 7 formed above the motorized grate 4 and the secondary combustion chamber 8 formed above the primary combustion chamber 7 Combustion chamber C; ash outlet 9 for discharging incineration ash; discharging combustion gas G 0 The exhaust gas outlet 10; the primary combustion air A 1 The primary combustion air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com