Chitosan porous functional layer of dustproof and antibacterial mask and preparation method of chitosan porous functional layer

A chitosan and functional layer technology, which is applied in the field of hygienic material preparation, can solve the problems of inability to effectively resist fine particles, poor moisture absorption and air permeability, and difficulty in breathing, and achieve uniform product structure, improved moisture absorption and air permeability, and good controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

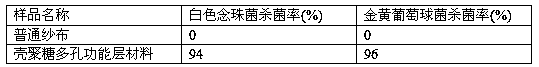

Examples

Embodiment 1

[0025] (1) Weigh 0.5 g of sodium alginate and dissolve it in 70 mL of water, add 5 mL of sodium periodate solution (40 mg / mL) dropwise, and react with electromagnetic stirring at room temperature for 4 hours. Add 100 μL of ethylene glycol dropwise to it, stir and react for 1 hour, then use a dialysis bag with a molecular weight cut-off of 3500 to soak in deionized water for dialysis for 24 hours, during which the water is changed every 2 hours, and the vacuum equipment is freeze-dried for 48 hours to obtain the aldehyde Sodium alginate solid.

[0026] (2) Weigh 0.5 g of carboxymethyl chitosan and dissolve it in 15 mL of water. During the process, ultrasonic or stirring is required for about 30 minutes to dissolve. At the same time, the following solution is prepared: 12.5 mg of the above-mentioned alginate sodium alginate is dissolved in 5 mL of water ; 0.75 g glycerol was dissolved in 0.5 mL water, 0.04 g poloxamer was dissolved in 4.5 mL water and 5 mL PBS.

[0027] (3) Add...

Embodiment 2

[0032] (1) Dissolve 0.75 g of starch in 75 mL of water, add 5 mL of sodium periodate solution (80 mg / mL) dropwise, and react with electromagnetic stirring at room temperature for 2 hours. Add 200 μL of ethylene glycol dropwise to it, react for another hour, and then use a dialysis bag with a molecular weight cut-off of 3500 to soak in deionized water for dialysis for 24 hours, during which the water is changed every 2 hours, and the vacuum equipment is freeze-dried for 48 hours to obtain aldehyde Starch.

[0033] (2) Weigh 1.0 g of carboxymethyl chitosan and dissolve it in 30 mL of water. During the process, ultrasonic or stirring is required for about 30 minutes to dissolve. At the same time, the following solution is prepared: 100 mg of the above-mentioned formaldehyde starch is dissolved in 10 mL of water; 0.75 1 g of glycerol was dissolved in 1 mL of water, and 0.30 g of poloxamer was dissolved in 10 mL of water.

[0034] (3) Add the prepared glycerin into the carboxymeth...

Embodiment 3

[0038] (1) Weigh 0.5 g of sodium alginate and dissolve it in 70 mL of water, add 5 mL of sodium periodate solution (40 mg / mL) dropwise, and react with electromagnetic stirring at room temperature for 4 hours. Add 100 μL of ethylene glycol dropwise to it, stir and react for 1 hour, then use a dialysis bag with a molecular weight cut-off of 3500 to soak in deionized water for dialysis for 24 hours, during which the water is changed every 2 hours, and the vacuum equipment is freeze-dried for 48 hours to obtain the aldehyde Sodium alginate solid.

[0039] (2) Dissolve 1.20 g of carboxymethyl chitosan in 55 mL of water, 60 mg of sodium alginate in 10 mL of water, 1.5 g of glycerol in 1 mL of water, and 0.30 g of poloxamer in 20 mL of water In water, 6 mg PEI was dissolved in 5 mL of water. Add glycerin to the above chitosan solution and stir for 5 min. Add the PEI solution to the chitosan solution and stir for 15 minutes. Then the sodium alginate solution was added dropwise into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com