Method for carrying out electrolytic treatment on copper-containing electroplating wastewater and recycling copper

A technology of electrolytic treatment and copper electroplating, applied in the direction of water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve problems such as difficult control, complicated process, secondary pollution, etc., achieve convenient collection, simple process flow, No secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

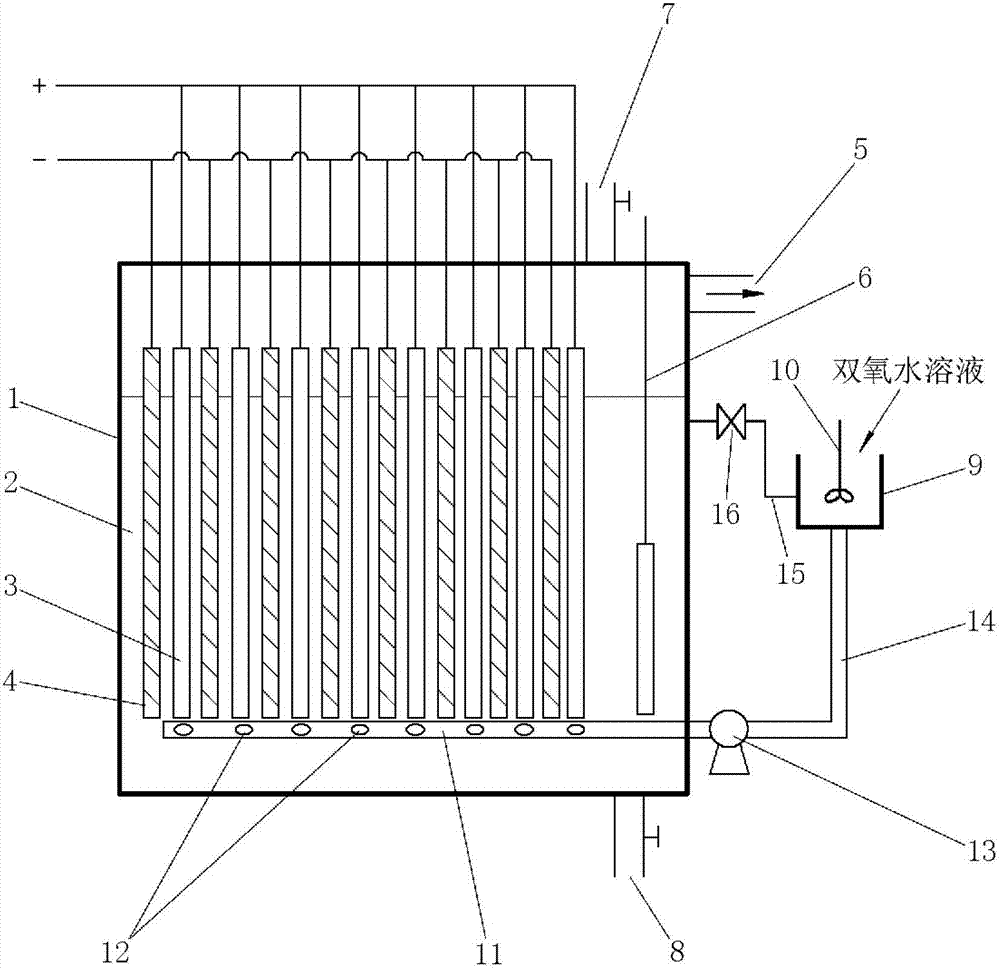

[0039] Refer to attached figure 1 , a method for electrolytically treating copper-containing electroplating wastewater and recovering copper. The electrolytic treatment of copper-containing electroplating wastewater is carried out through an electrolytic treatment of copper-containing electroplating wastewater. The electrolytic treatment of copper-containing electroplating wastewater includes an electrolytic cell 1 and an electrolyte stirring device. The electrolytic cell 1 adopts a glass electrolytic cell, the anode 3 adopts a titanium-based platinum electrode, and the cathode 4 adopts a copper electrode. The anode 3 and the cathode 4 are arranged alternately in a unipolar parallel manner, and an exhaust port 5 and a feed port are arranged on the top of the electrolytic cell 1 7. A valve is provided on the feed port 7, a pH meter 6 is provided in the electrolytic cell 1, a discharge port 8 is provided at the bottom of the electrolytic cell 1, and a valve is provided on the dis...

Embodiment 2

[0042] Refer to attached figure 1 , The electrolytic treatment of copper-containing electroplating wastewater device for electrolytic purification of copper-containing electroplating wastewater is the same as in Example 1. The method for electrolytic treatment of copper-containing electroplating wastewater is: before electrolytic treatment, add an appropriate amount of quicklime to the electroplating copper-containing wastewater with a concentration of 15.8mg / L, adjust the pH value of the wastewater to 6.9, and filter to remove sediment; pass the filtrate through the The feed port 7 enters the electrolytic cell 1 as the electrolyte 2, and then adds appropriate amounts of NaCl and KCl in the electrolyte 2 at a molar ratio of 1:1, so that the content of chloride ions in the solution is twice the content of copper ions, and the anode The distance between 3 and cathode 4 is 4.5mm; during electrolysis, pass 5.0V direct current, slowly add 30% hydrogen peroxide solution to the anode...

Embodiment 3

[0044] Refer to attached figure 1 , The electrolytic treatment of copper-containing electroplating wastewater device for electrolytic purification of copper-containing electroplating wastewater is the same as in Example 1. The method of electrolytic treatment of copper-containing electroplating wastewater is: before electrolytic treatment, add an appropriate amount of quicklime to the electroplating copper-containing wastewater with a concentration of 384mg / L, adjust the pH value of the wastewater to 7.0, and filter to remove sediment; pass the filtrate through the feed Port 7 enters the electrolytic cell 1 as the electrolyte 2, and then adds an appropriate amount of NaCl and KCl in the electrolyte 2 at a molar ratio of 1:1, so that the content of chloride ions in the solution is twice the content of copper ions, and the anode 3 The distance between the cathode and the cathode 4 is 15mm; during electrolysis, connect 16.0V direct current, slowly add 30% hydrogen peroxide soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com