Concrete expansion agent containing circulating fluidized bed combustion coal solid sulfur clinker

A coal-fired sulfur-fixing ash and circulating fluidized bed technology, applied in the field of concrete expansion agent composition, can solve the problems of complex production process and high production cost, and achieve the effect of simple production process, low cost and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A concrete expansion agent containing coal-fired sulfur-fixing ash in a circulating fluidized bed, its composition and mass percentage examples are: 35% of sulfur-fixing ash, 60% of anhydrite, and 5% of lithium slag.

[0025] Preparation method: take each component according to the stated ratio, after crushing and grinding, mix them evenly in a mixer to obtain the product—concrete expansion agent containing coal-fired sulfur-fixing ash in a circulating fluidized bed .

[0026] The performance of the product has been tested to meet the requirements of GB23439-2009.

Embodiment 2

[0028] A concrete expansion agent containing coal-fired sulfur-fixing ash in a circulating fluidized bed, its composition and mass percentage examples are: 40% of sulfur-fixing ash, 50% of anhydrite, and 10% of lithium slag.

[0029] The preparation method is the same as in Example 1. The product—concrete expansion agent containing coal-fired sulfur-fixed ash of circulating fluidized bed has been tested for limited expansion of clean mortar, and the limited expansion rate in water for 7 days is >0.025%, and the expansion rate in air for 21 days is <-0.02%, which meets GB23439-2009 Require.

Embodiment 3-9

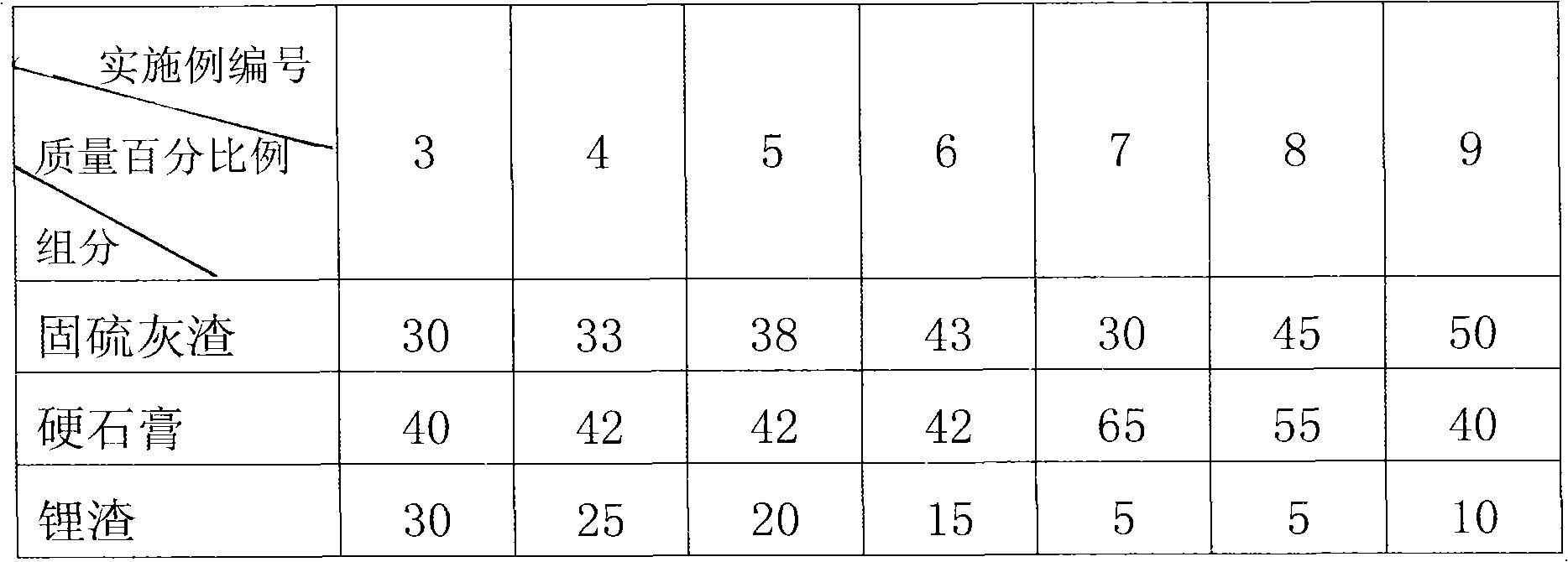

[0031] A concrete expansion agent containing coal-fired sulfur-fixing ash in a circulating fluidized bed, its composition and mass percentage are shown in the following table:

[0032]

[0033] The preparation method of embodiment 3-9 is equal to embodiment 1 or 2, omission.

[0034] In the foregoing embodiment: the main chemical composition and mass percentage of the described sulfur-fixing ash can be SiO 2 25.82~43.66%, SO 3 1.26~12.68%, CaO 2.85~21.35%, Al 2 o 3 11.84~28.62%, Fe 2 o 3 3.41~14.28%, K 2 O 0.54~1.09%, Ti 2 O 0.32~1.42%; for example: SiO 2 31.06%, SO 3 11.60%, CaO 19.45%, Al 2 o 3 12.00%, Fe 2 o 3 11.34%, K 2 O 0.55%, Ti 2 O 0.32%; it can also be composed of other mass percentages of sulfur-fixing ash in the prior art.

[0035] In the above-described embodiment: the main chemical composition and mass percentage of the lithium slag can be SiO 2 47.73~58.28%, Al 2 o 3 17.01~18.88%, Fe 2 o 3 1.22~2.7%, CaO 5.57~10.06%, MgO 0.16~1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com