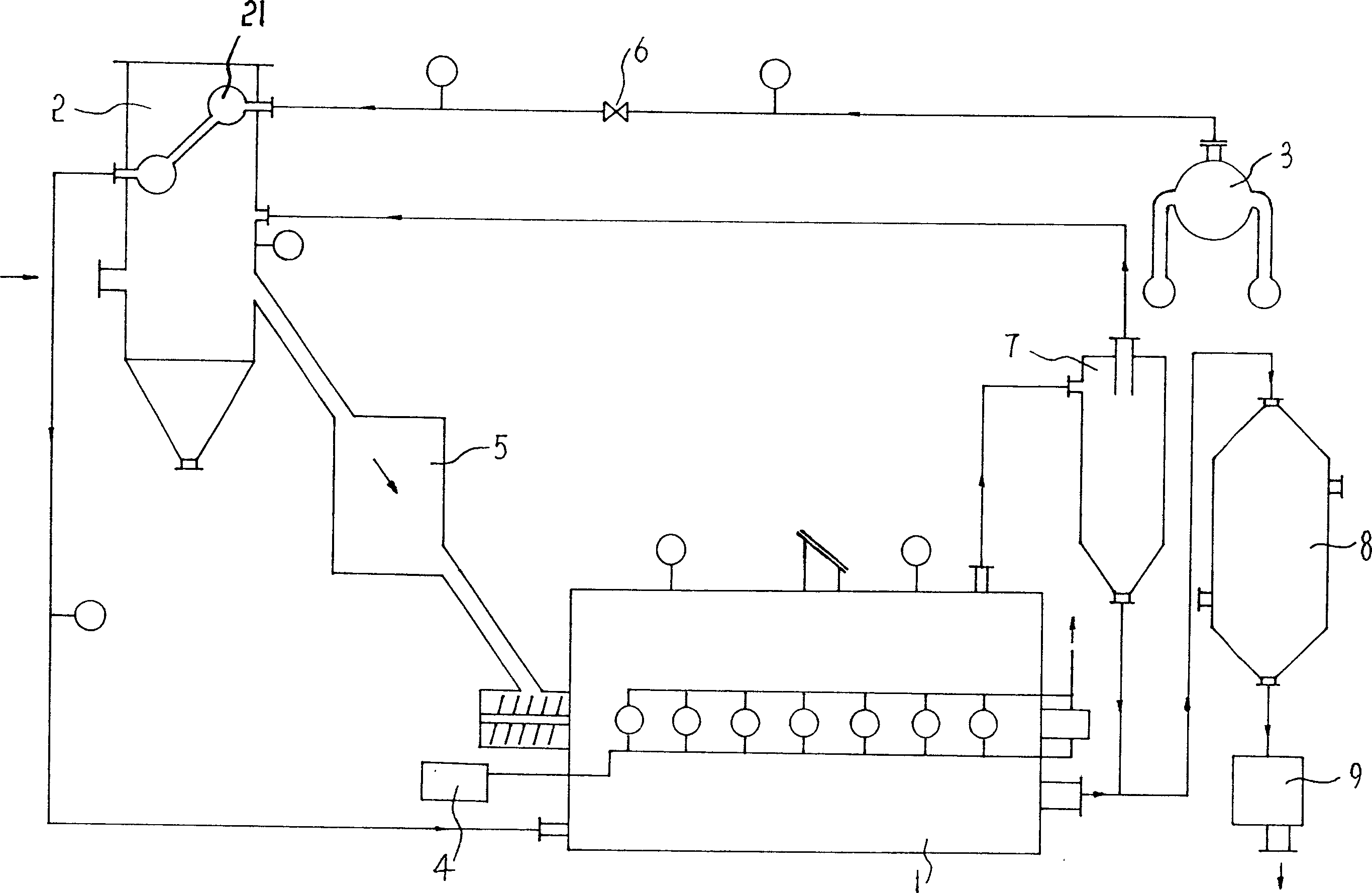

Method and device for manufacturing reduced iron using microwave fluid bed

A fluidized bed and reduced iron technology, applied in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of long heating time, high energy consumption, high price, etc., to reduce secondary energy consumption, and to achieve reasonable process routes. , the effect of reducing smelting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

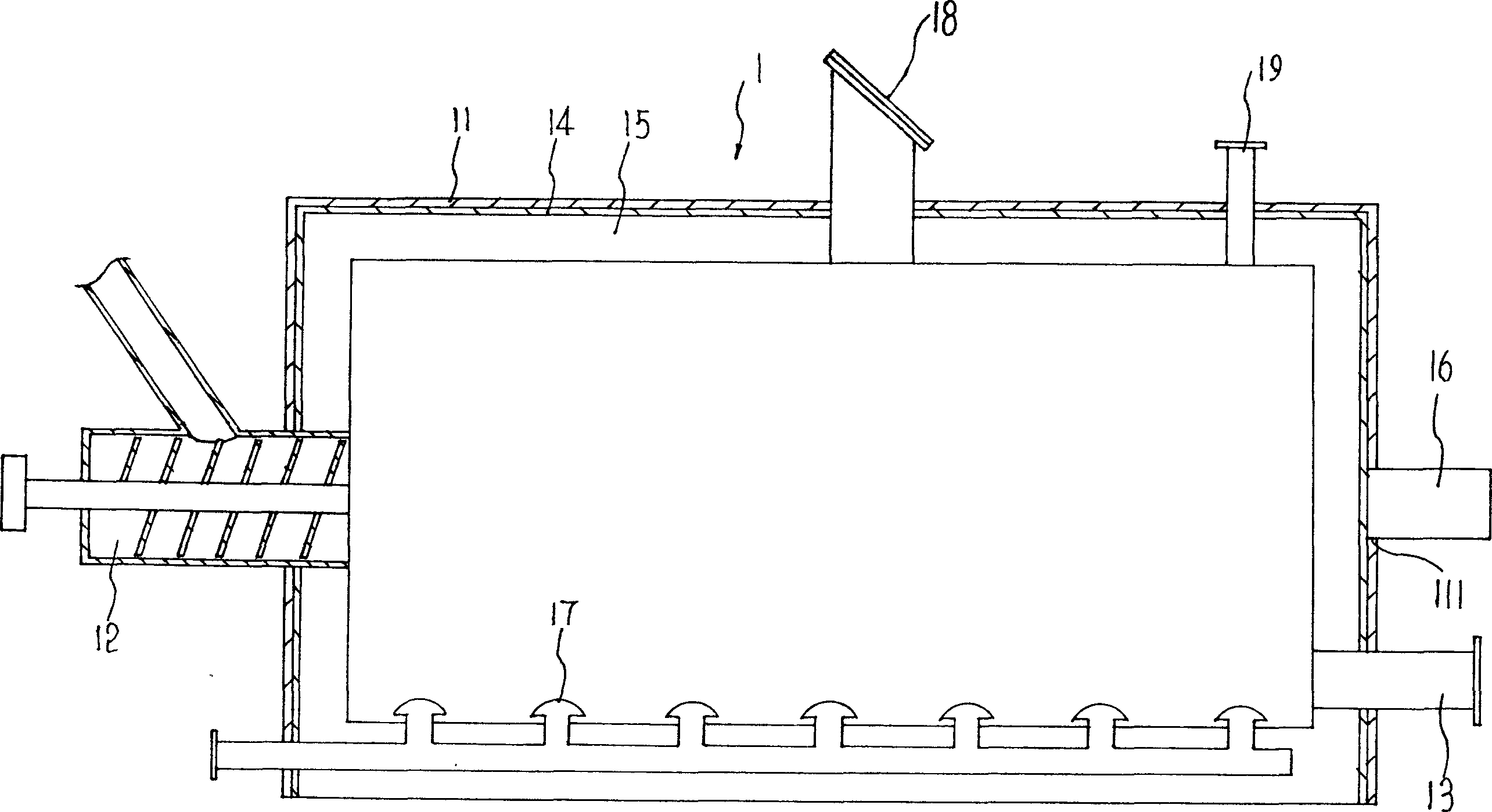

Embodiment 1

[0020] The iron-containing raw material is limonite with 55% iron content produced in Guangxi, crushed to -150 mesh, and the carbon-containing raw material is 6500 white coal, crushed to -80 mesh, the ore-to-coal ratio is 1:0.3, and a conventional fluidized bed The volume ratio to the microwave fluidized bed is 8:1, the microwave frequency is 2.45GHz, the temperature range of the first-stage conventional fluidized bed is 1050±30°C, the temperature in the microwave fluidized bed is maintained at 1020°C, and the superheated steam is maintained at Above 550°C, the residence time of the material in the microwave fluidized bed is 8 minutes, the reaction material is cooled to below 50°C, and the material is discharged. After magnetic separation, the total Fe content of reduced iron is 86%, the meltable iron is 80%, and the metal yield is 78% %.

Embodiment 2

[0022] The iron-containing raw material is limonite with 55% iron content produced in Guangxi, which is pulverized to -100 mesh, and the carbon-containing raw material is white coal, which is pulverized to -80 mesh, and the ore-coal ratio is 1: 0.35. The volume ratio of the microwave fluidized bed is 6:1, the microwave frequency is 2.45GHz, the temperature range of the first-stage conventional fluidized bed is 1150±30°C, the temperature in the microwave fluidized bed is maintained at 1100°C, and the superheated steam is maintained at more than 550°C, the residence time of the material in the microwave fluidized bed is 9 minutes, the reaction material is cooled to below 50°C, and the material is discharged. After magnetic separation, the total Fe content of reduced iron is 83%, the meltable iron is 80%, and the metal yield is 70%. .

Embodiment 3

[0024] The iron-containing raw material is hematite with 48% iron produced in Guangxi, crushed to -120 mesh, and re-selected to a total iron content of 55%; the carbon-containing raw material is white coal, crushed to -80 mesh, and the ore-to-coal ratio is 1 : 0.35, the volume ratio of the primary conventional fluidized bed to the microwave fluidized bed is 8:1, the microwave frequency is 2.45GHz, the temperature range of the primary conventional fluidized bed is 950±30°C, the temperature in the microwave fluidized bed Maintain at 900°C, superheated steam at more than 550°C, residence time of the material in the microwave fluidized bed is 9 minutes, the reaction material is cooled to below 50°C, and the total Fe content of the reduced iron is 90% after magnetic separation, which can be The molten iron is 83%, and the metal yield is 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com