melting furnace

A melting furnace and furnace body technology, applied in the field of smelting, can solve the problems of incomplete melting of metal slag, lower metal effective utilization rate, limited burning time, etc., achieve good melting effect, fast melting speed, and increase heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

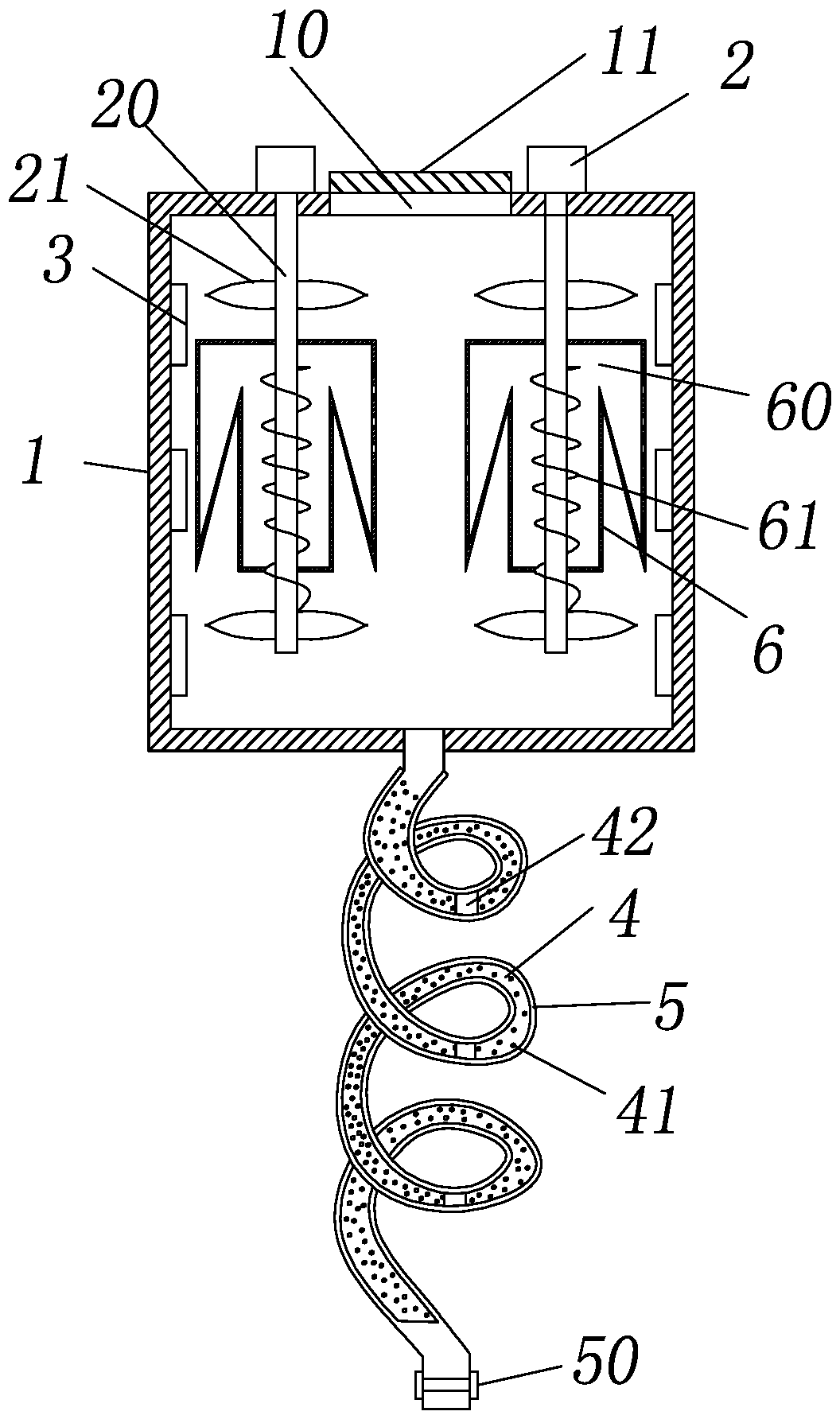

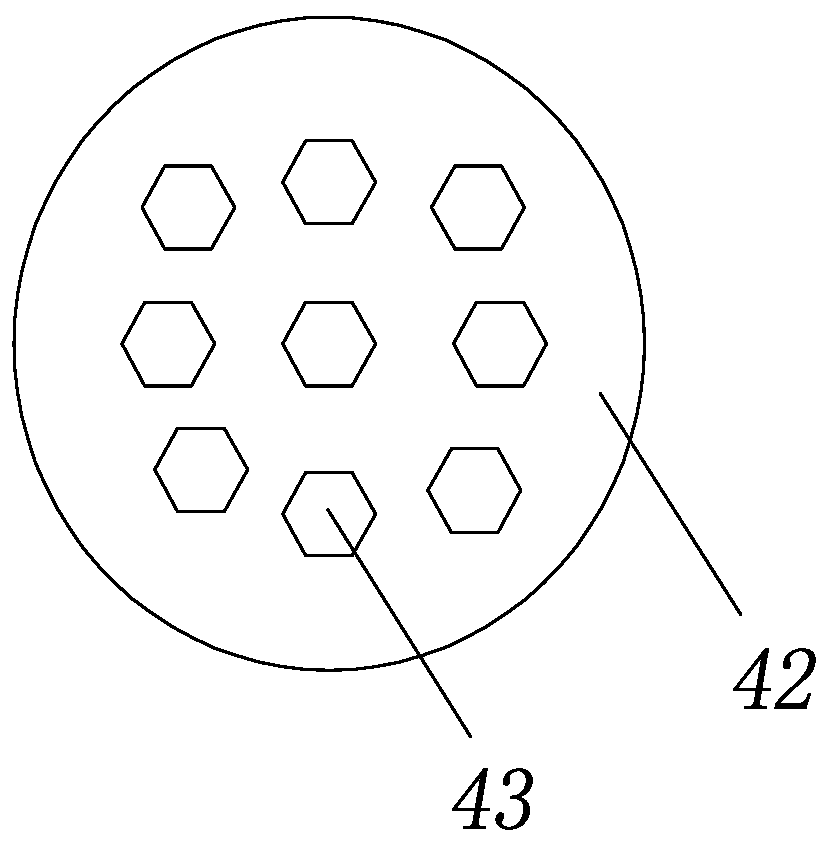

[0022] The reference signs in the drawings of the description include: furnace body 1, feeding port 10, furnace cover 11, motor 2, stirring rod 20, stirring blade 21, heater 3, slag storage pipe 4, mesh 41, mesh plate 42, net Hole 43, fluid pipe 5, liquid discharge valve 50, slag storage box 6, material inlet 60, helical blade 61.

[0023] The embodiment is basically as attached figure 1 Shown: the melting furnace includes a cylindrical body of furnace 1, the top of the body of furnace 1 is provided with a circular feeding port 10, and the feeding port 10 is hinged with a circular furnace cover 11 for covering the feeding port 10, and The furnace cover 11 rotates horizontally relative to the feeding port 10 to avoid vertical overturning and prevent workers from accidentally touching the high-temperature furnace cover 11 . Two motors 2 are installed on the top of the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com